Enhanced compounded mix multi-stage alternate wetland sewage treating process and apparatus thereof

A technology for artificial wetland and sewage treatment, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of poor impact load resistance, long hydraulic retention time, nitrogen and phosphorus removal Poor capacity and other problems, to achieve the effect of strong impact load resistance, reduced floor space, and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

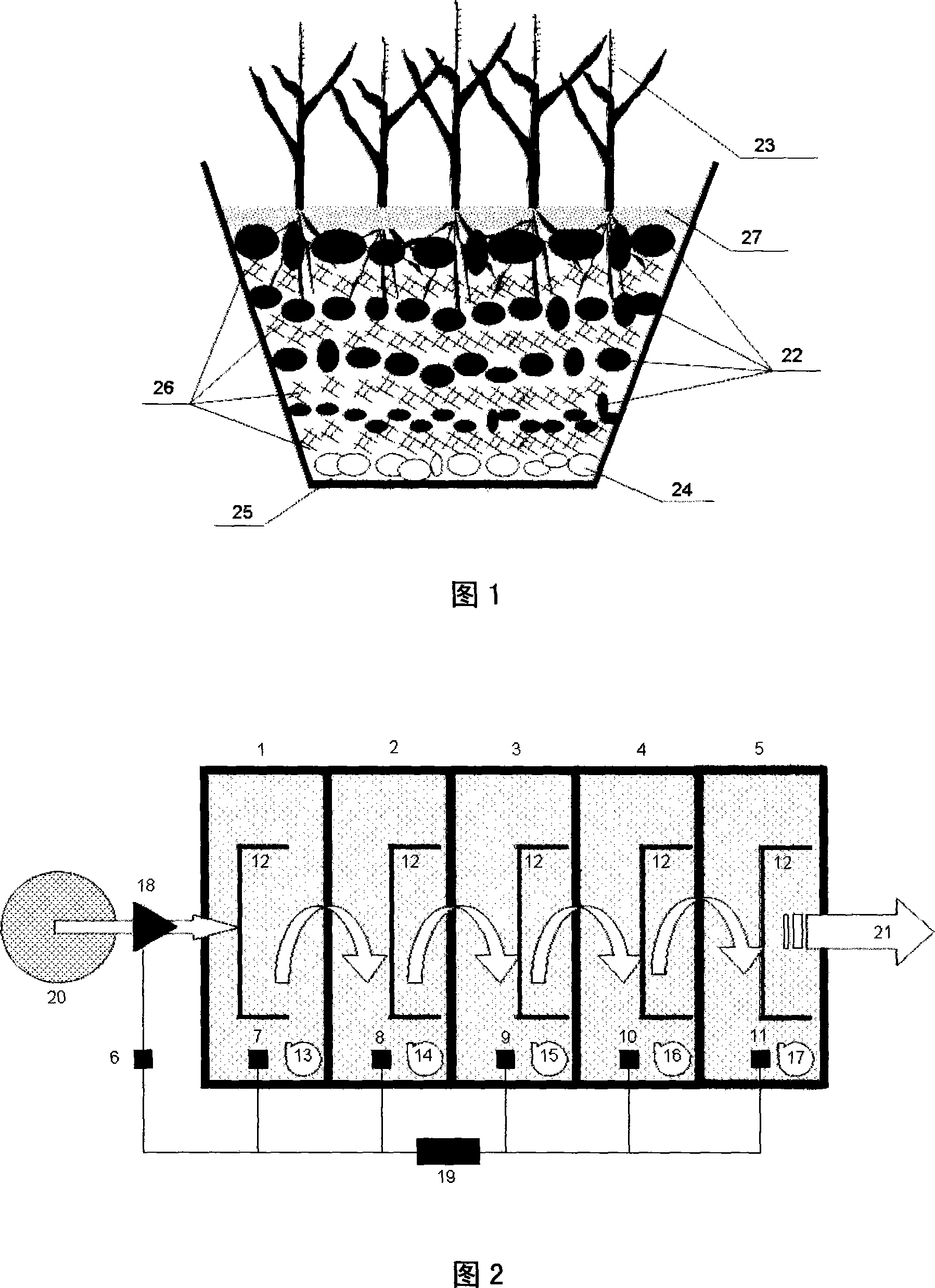

[0013] The main components of the multi-stage alternating constructed wetland are: five rectangular vertical flow wetland units, PLC programmable controller, water inlet / outlet solenoid valve, suction pump, water distribution system and connecting pipelines. The bed walls of the five wetland units are made of impermeable materials. Each unit is a mixed packing layer with a thickness of 55 cm, filled with dewatered sludge and gravel of different particle sizes, and filled according to the reverse particle size (see Figure 1). The water distribution pipes are distributed at 5-10cm on the surface of the composite filler, and the distribution is uniform. Local dominant plants such as reeds are selected as wetland plants.

[0014] Fig. 2 is the operating condition diagram of the present invention, and the stage operation time and residence time can be adjusted according to different water quality and water quantity requirements. The first wetland unit 1 is flooded, the second wetl...

Embodiment 2

[0019] Add domestic sewage with average concentrations of COD, ammonia nitrogen, total nitrogen, and total phosphorus at 130mg / L, 16.7mg / L, 17.6mg / L, and 1.75mg / L, and strengthen the composite filler multi-stage alternating wetland system for COD, ammonia nitrogen, and total The removal rates of nitrogen and total phosphorus are 95%, 90%, 89% and 98% respectively, and the average concentrations of COD, ammonia nitrogen, total nitrogen and total phosphorus in the treated effluent are 6.5mg / L, 1.67mg / L, 1.94mg / L, 0.04mg / L, reaching the sewage reuse standard.

Embodiment 3

[0021] Each wetland unit is filled with dewatered sludge from waterworks, gravel, crushed stone and soil. The wetland filling thickness is 45-65cm. The top layer of the bed is covered with soil. Reeds or local dominant plants are planted on the soil. A mud layer and a gravel layer, the bottom layer is an anti-seepage layer, and the particle size of the sludge layer decreases from top to bottom.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com