Catalyst for denitrification and dedioxin

A technology for removing dioxins and catalysts is applied in the field of denitration and dedioxin removal catalysts and their preparation, which can solve the problems of inability to perform normal filtration reaction, blockage of honeycomb strip holes, increase production costs, etc., and achieve high anti-dust interference ability, The effect of preventing volume shrinkage and reducing environmental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with specific examples, which do not limit the present invention.

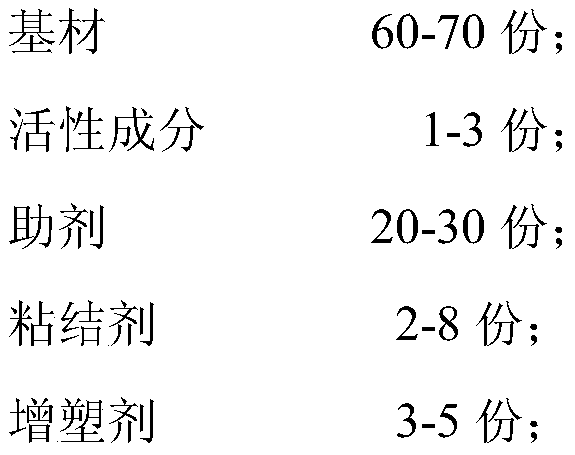

[0046] A kind of denitration and dedioxin catalyst is made by following raw material, and described parts are weight parts:

[0047] 60-70 parts of substrate;

[0048] Active ingredient 1-3 parts;

[0049] Auxiliary 20-30 parts;

[0050] Binder 2-8 parts;

[0051] 3-5 parts of plasticizer;

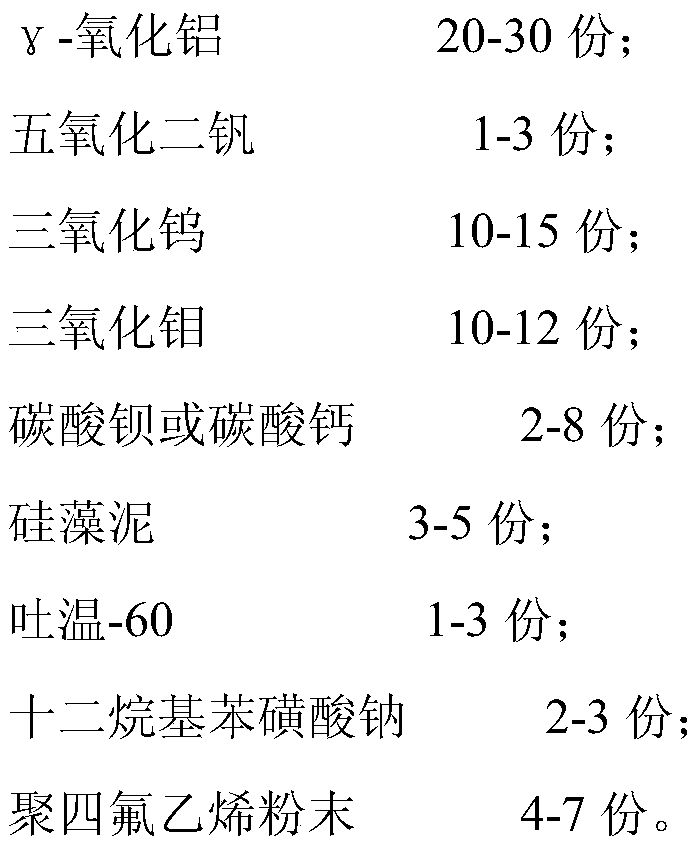

[0052] Wherein the base material includes titanium dioxide, silicon powder and γ-alumina.

[0053] Each composition and consumption in the specific embodiment see the following table:

[0054] Element Embodiment one Embodiment two Embodiment three Substrate 60 copies 65 copies 70 copies active ingredient 1 copy 1.2 parts 3 copies Auxiliary 20 copies 25 copies 30 copies binder 2 copies 25 copies 8 servings plasticizer 3 copies 3.7 servings 5 copies extrude lubricant 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com