Macrotype metal mold system for recovering thermal energy by cooling water

A heat recovery and metal mold technology, applied in the field of metallurgy, can solve problems such as high ambient temperature, poor cooling effect, and environmental pollution, and achieve the effects of broad application prospects, reasonable structural design, and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

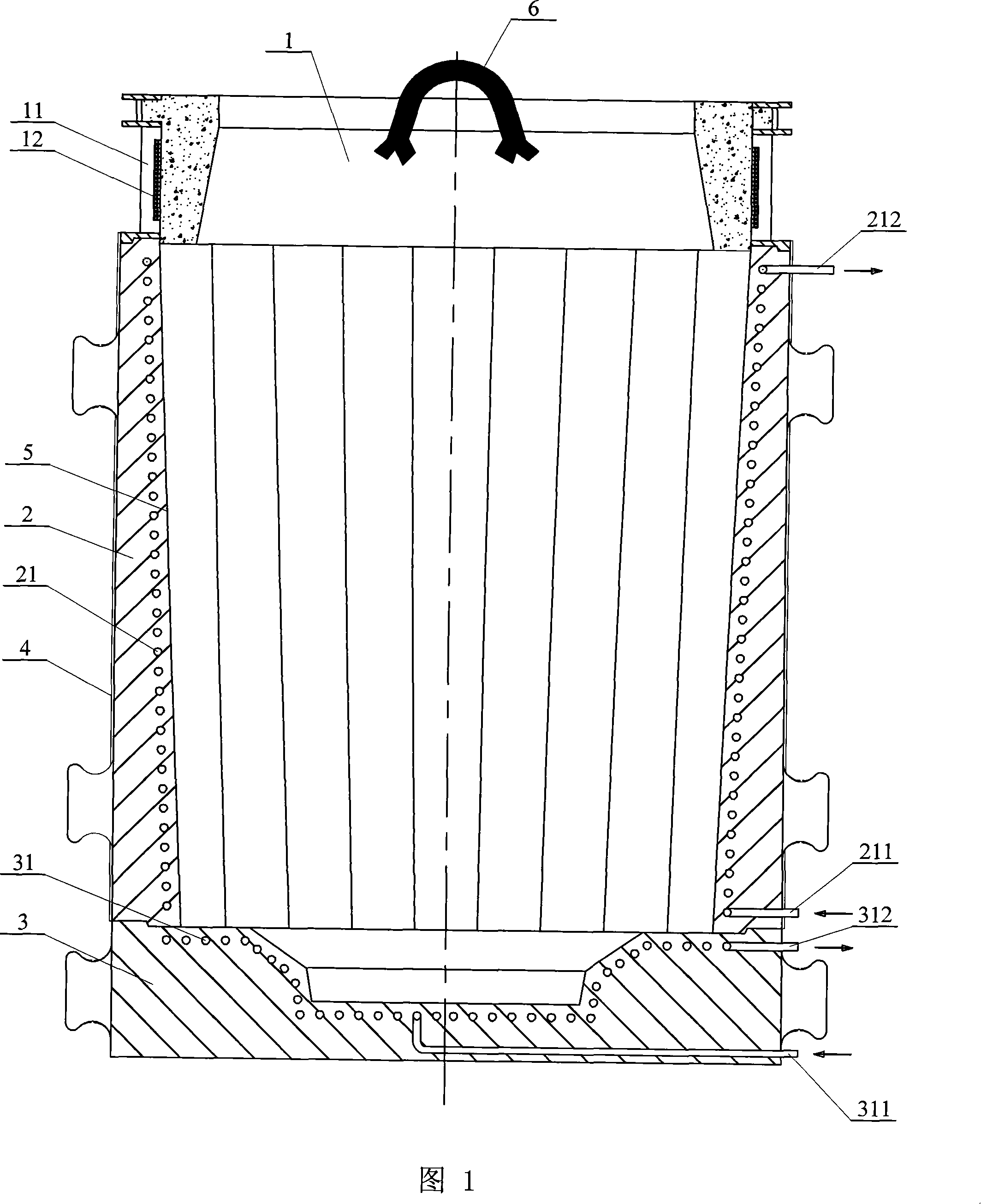

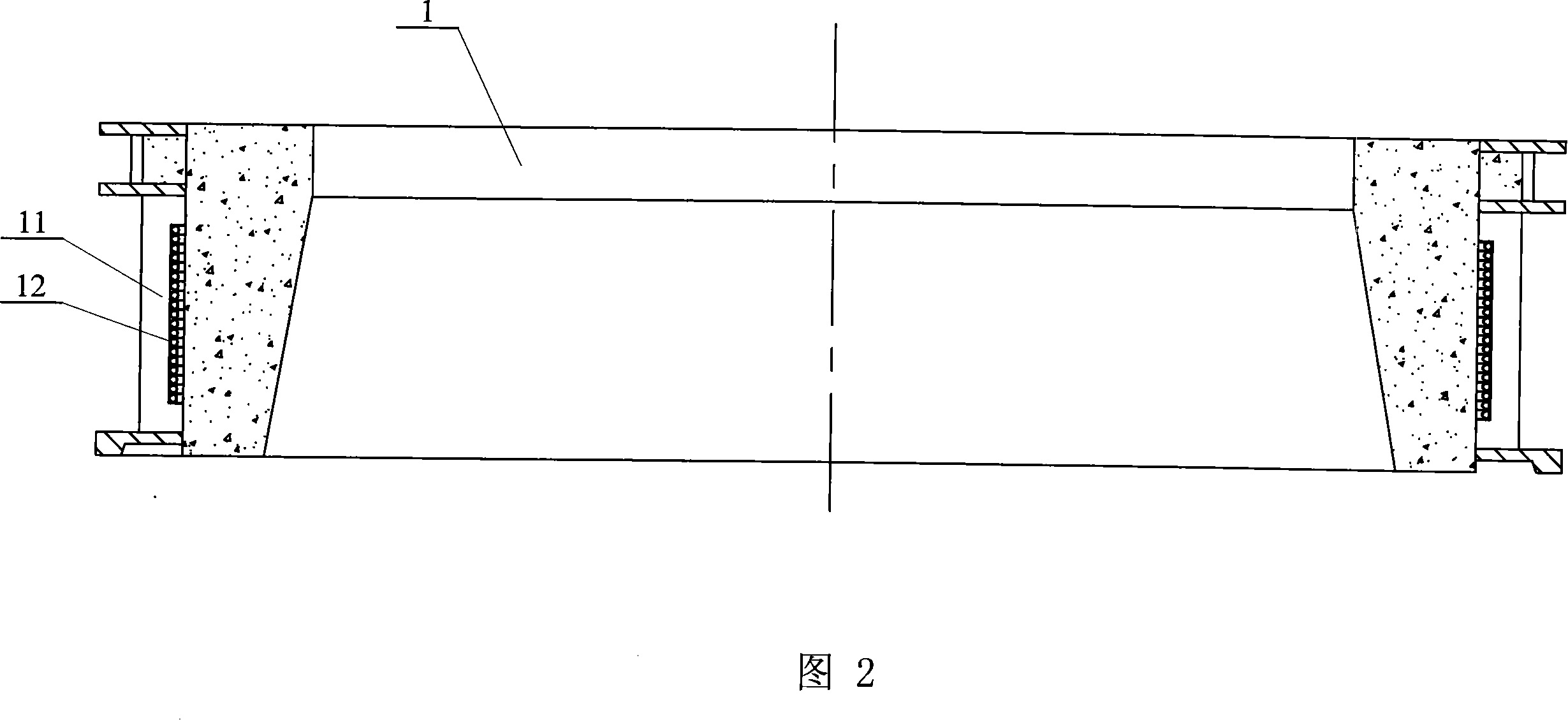

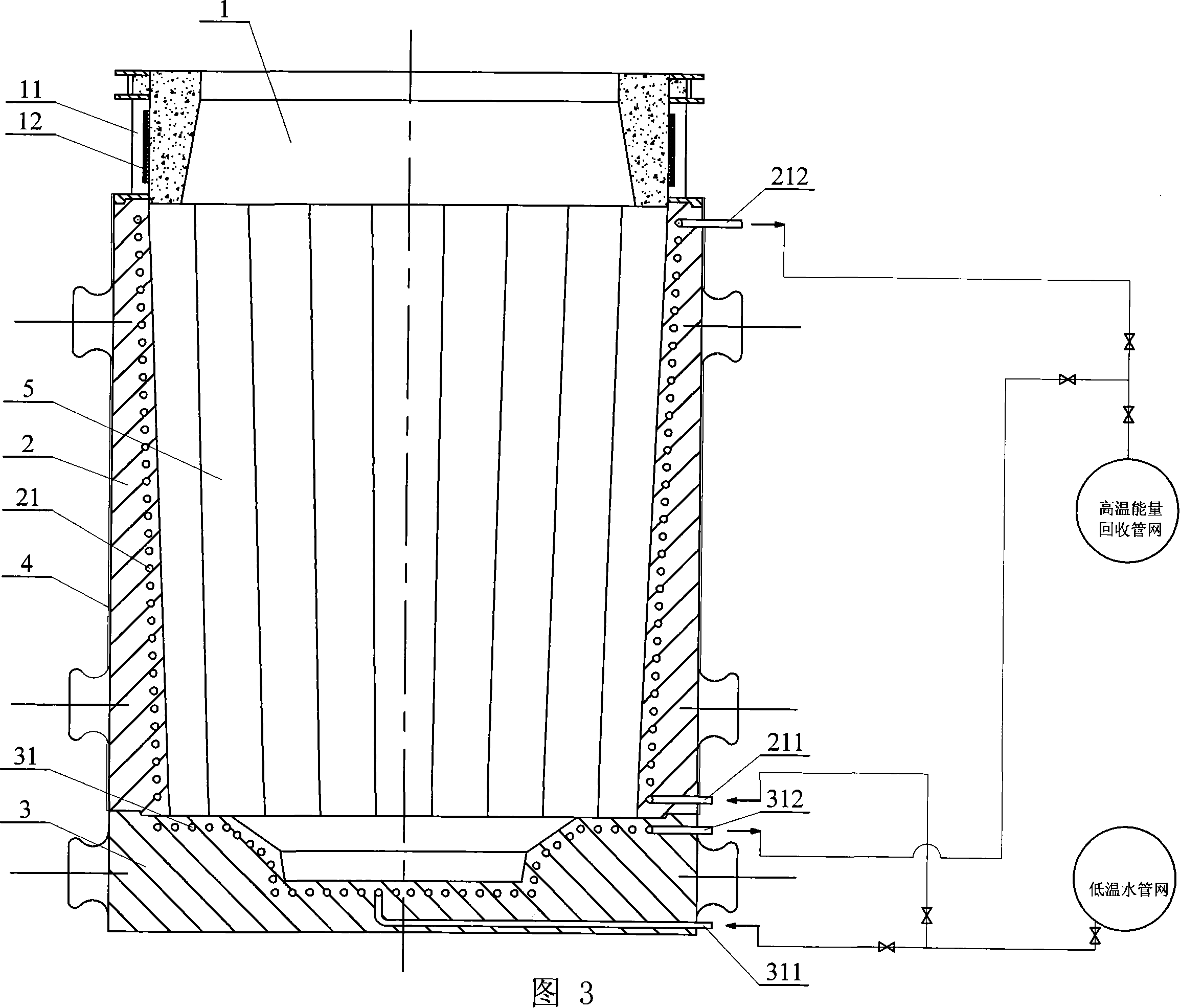

[0016] The specific implementation will be described in detail below in conjunction with the accompanying drawings.

[0017] As shown in Figure 1, this embodiment includes a water-cooled heat energy recovery metal mold, a low-temperature water supply pipe network 7, and a hot water energy recovery pipe network 8. The magnetic induction heating riser 1 and the metal mold chassis 3, the inside of the metal mold 2 is provided with a cooling water pipe 21, and the outer surface of the metal mold 2 is fixedly provided with water inlet pipes communicating with the water inlet and outlet of the cooling water pipe 21 respectively Head 211 and water outlet pipe head 212; the inside of the metal mold chassis 3 is provided with a cooling water pipe 22, and the outer surface of the metal mold chassis 2 is fixedly provided with a water inlet pipe head communicating with the water inlet and outlet of the cooling water pipe 22 respectively 221 and water outlet pipe head 222; wherein the cool...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com