Sodium-air heat exchanger

An air heat exchanger, argon technology, applied in the direction of indirect heat exchanger, heat exchanger type, climate sustainability, etc., can solve problems that have not been reported yet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

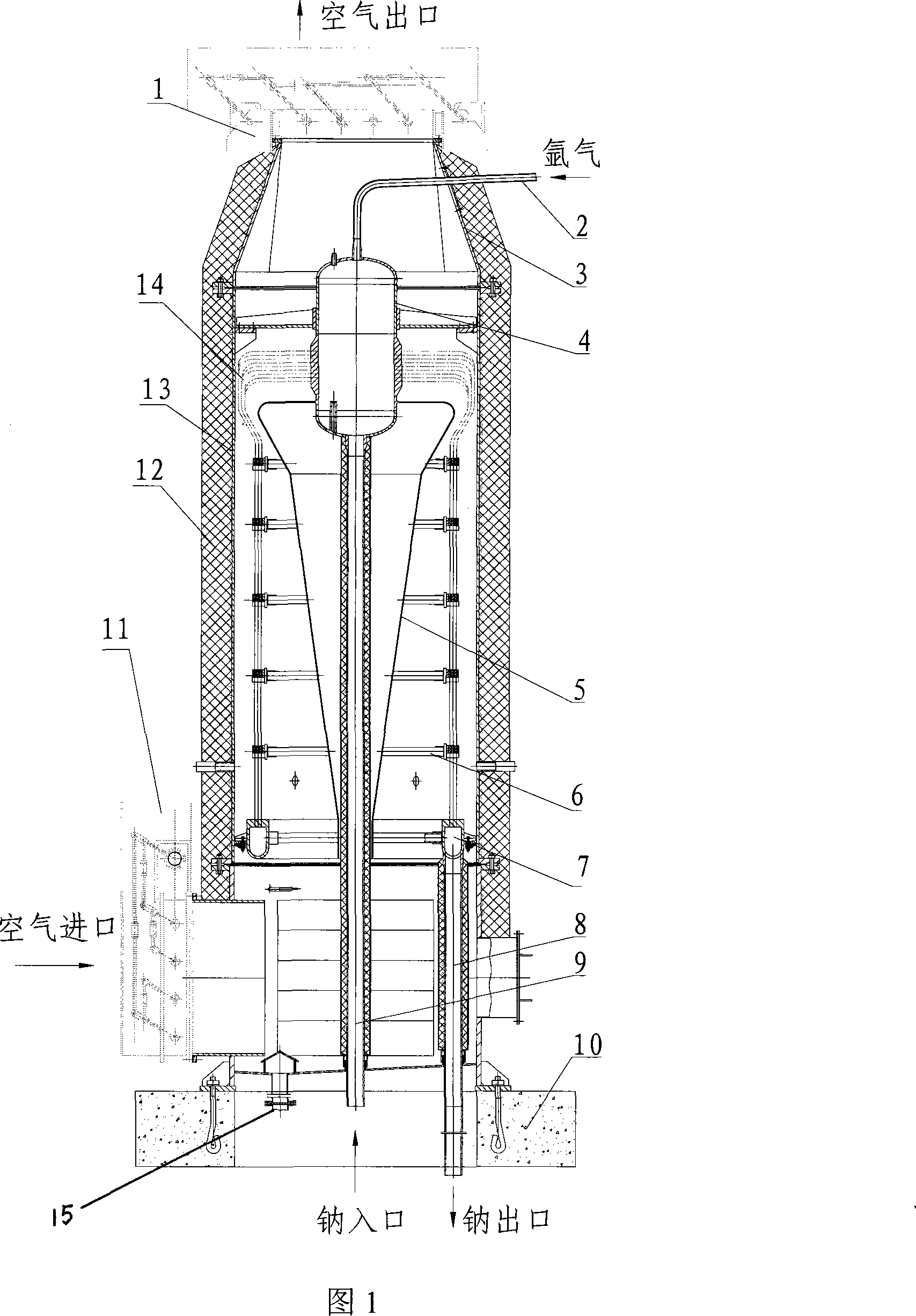

[0011] The technical solution of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0012] A sodium-air heat exchanger, which includes a cylinder 3, which is fixed on a concrete floor 10. An outlet damper 1 is provided at the top of the barrel 3, and an inlet damper 11 is provided at the bottom. The inlet damper 11 is a single-section inlet damper, and there are three arranged at an angle of 90° to each other to ensure that the air is evenly distributed according to the pipe system. The outlet damper 1 is a double-stage outlet damper. Each damper rotary guide vane can rotate and be fixed within the range of 0-90 degrees. An expansion tank 4 is arranged on the top of the inner cavity of the cylinder body 3, which is a vertical cylindrical container with a free surface of sodium, and is fixed on the inner side wall of the cylinder body 3 by a support plate. The top of the expansion tank 4 is provided with an argon inlet con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com