Separation process of removing dimethyl ether impurities in chloromethane through water absorption

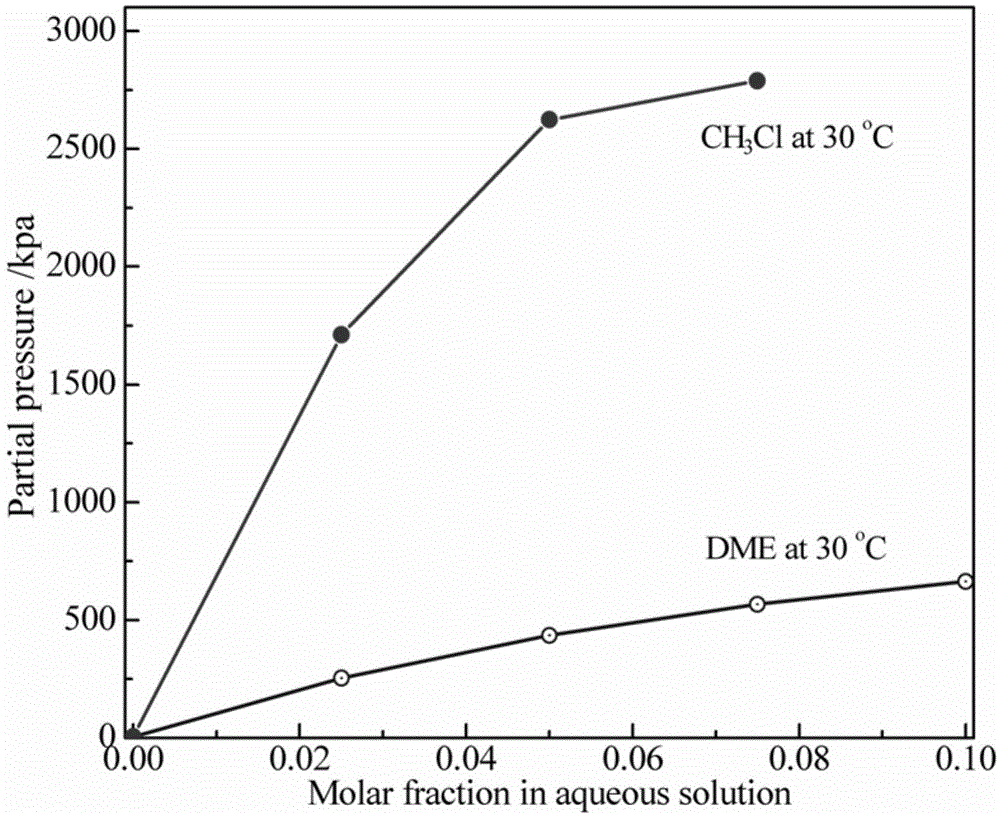

A technology of dimethyl ether and methyl chloride, applied in the field of gas separation and purification, can solve problems such as low solubility of methyl chloride, and achieve the effects of simple regeneration process and low regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

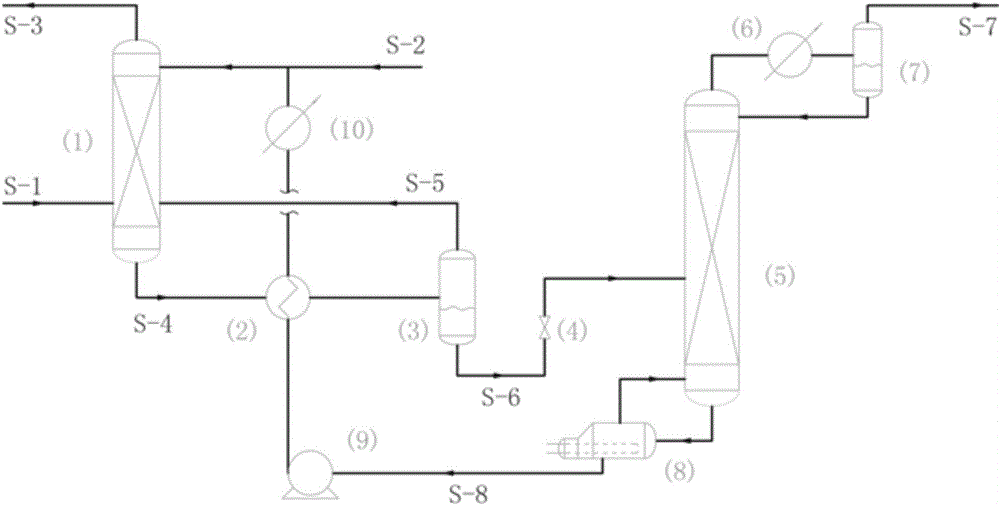

[0026] Crude methyl chloride (S-1) from the dehydration unit with a flow rate of 450Nm 3 / h, containing 75mol% of methyl chloride and 25mol% of dimethyl ether, enters the absorption tower (1) from the bottom under the conditions of 0.2MPaG and 15°C, and flows from bottom to top.

[0027] The fresh absorbent (S-2, pure water, the supplementary amount is about 6kg / h) and the cooled regenerated absorbent (S-8) are joint stock, with a total flow rate of 3.75t / h, and enter the absorption tower (1) from the top , flowing from top to bottom.

[0028] In the absorption tower (1), the dimethyl ether impurity enters the liquid phase by the gas phase due to the hydrogen bond, and most of the methyl chloride cannot enter the absorbent; the absorption tower (1) top extracts the methyl chloride ( S-3), the volume flow rate is 335Nm 3 / h, the dimethyl ether content is then reduced to 0.3mol%; the rich absorption liquid (S-4) is extracted from the bottom of the absorption tower (1), the con...

Embodiment 2

[0037] Crude methyl chloride (S-1) from the dehydration unit with a flow rate of 450Nm 3 / h, containing 75mol% of methyl chloride and 25mol% of dimethyl ether, enters the absorption tower (1) from the bottom under the conditions of 0.5MPaG and 35°C, and flows from bottom to top.

[0038] The fresh absorbent (S-2, pure water, the supplementary amount is about 6kg / h) and the cooled regenerated absorbent (S-8) are joint stock, with a total flow rate of 2.98t / h, and enter the absorption tower (1) from the top , flowing from top to bottom.

[0039] In the absorption tower (1), the dimethyl ether impurity enters the liquid phase by the gas phase due to the hydrogen bond, and most of the methyl chloride cannot enter the absorbent; the absorption tower (1) top extracts the methyl chloride ( S-3), the volume flow rate is 328Nm 3 / h, the dimethyl ether content is then reduced to 0.3mol%; the rich absorption liquid (S-4) is extracted from the bottom of the absorption tower (1), the con...

Embodiment 3

[0048] Crude methyl chloride (S-1) from the dehydration unit with a flow rate of 450Nm 3 / h, containing 75mol% of methyl chloride and 25mol% of dimethyl ether, enters the absorption tower (1) from the bottom under the conditions of 0.2MPaG and 15°C, and flows from bottom to top.

[0049] Fresh absorbent (S-2, CaCl 2 The aqueous solution with a mass concentration of 15%, the supplementary amount is about 2kg / h) is combined with the cooled regenerated absorbent (S-8), and the total flow rate is 4.5t / h, and enters the absorption tower (1) from the top. flow down.

[0050] In the absorption tower (1), the dimethyl ether impurity enters the liquid phase by the gas phase due to the hydrogen bond, and most of the methyl chloride cannot enter the absorbent; the absorption tower (1) top extracts the methyl chloride ( S-3), the volume flow rate is 336Nm 3 / h, the dimethyl ether content is then reduced to 0.2mol%; the rich absorption liquid (S-4) is extracted from the bottom of the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com