Method and device for checking oil channel sealing of engine cylinder

A technology of engine cylinder block and inspection method, which is applied in the direction of engine test, measuring device, liquid tightness measurement using liquid/vacuum degree, etc., which can solve problems such as inconvenient operation, leakage of rubber rod trimming, and difficulty in sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

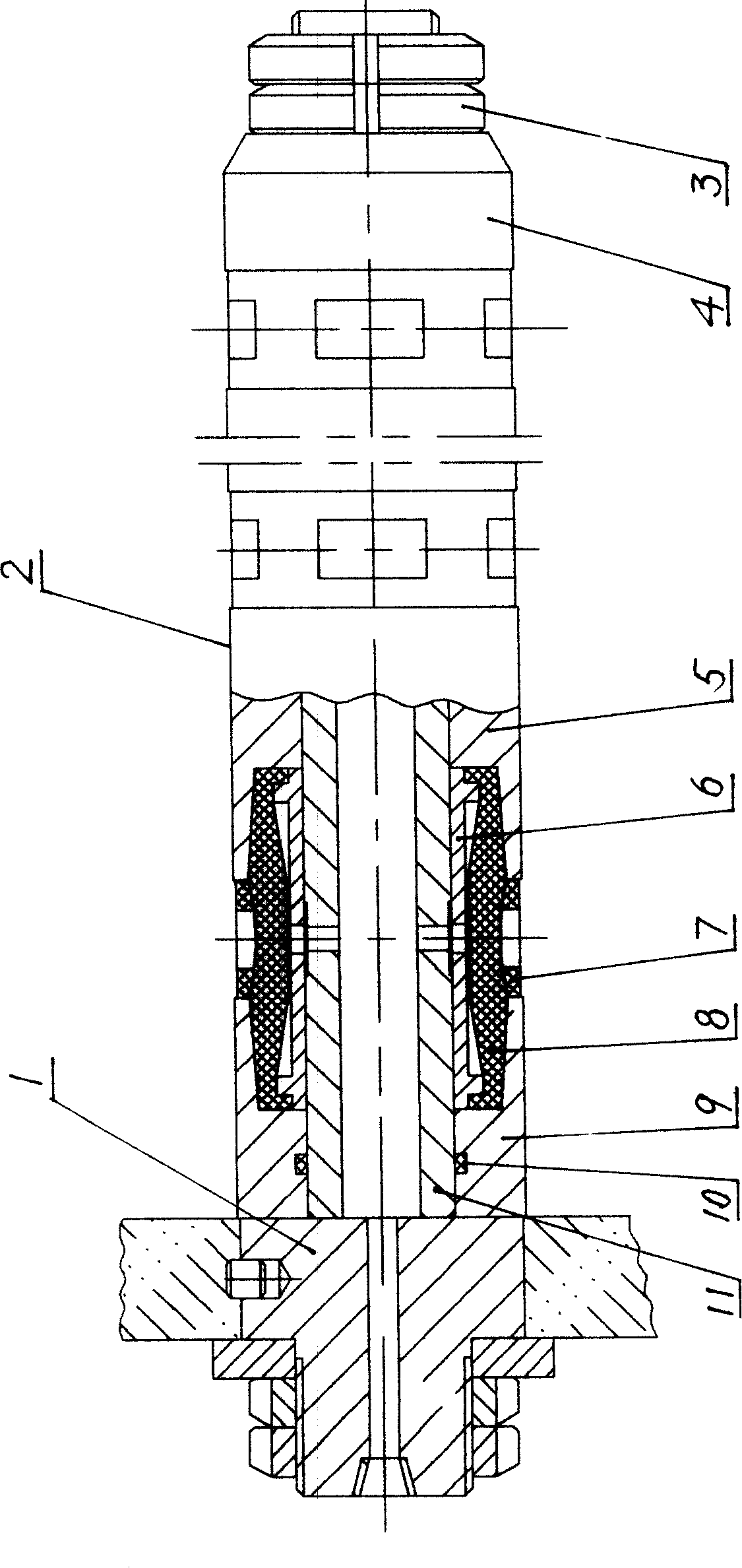

[0015] Referring to the accompanying drawings, the inspection device is provided with an expanding core sealing shaft 2 and a joint 1 installed at one end thereof. Inside the expanding core sealing shaft, there is a mandrel 11 with an axial inner hole. One end of the inner hole of the mandrel is blocked, and the mandrel There are five expansion rings 8 made of oil-resistant rubber on the periphery. The cavity inside the expansion ring is connected with the inner hole of the mandrel. There are spacers 5 between adjacent expansion rings. There are stop rings on the outer end faces of the expansion rings at both ends. 4 and 9, and are compressed by the nut 3, and the joints of the spacer, the retaining ring and the expansion ring are sealed. A transition sleeve 6 is provided between the expansion ring and the mandrel, and a through hole aligned with the through hole on the mandrel is provided on the transition sleeve, and a sealing ring 10 is provided at the junction between the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com