Multifunctional slagging material findings and method for producing the same

A multi-functional, slag-making technology, applied in the field of metallurgy, can solve problems such as efficient material utilization, and achieve the effects of saving consumption, reducing total amount, and accelerating chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

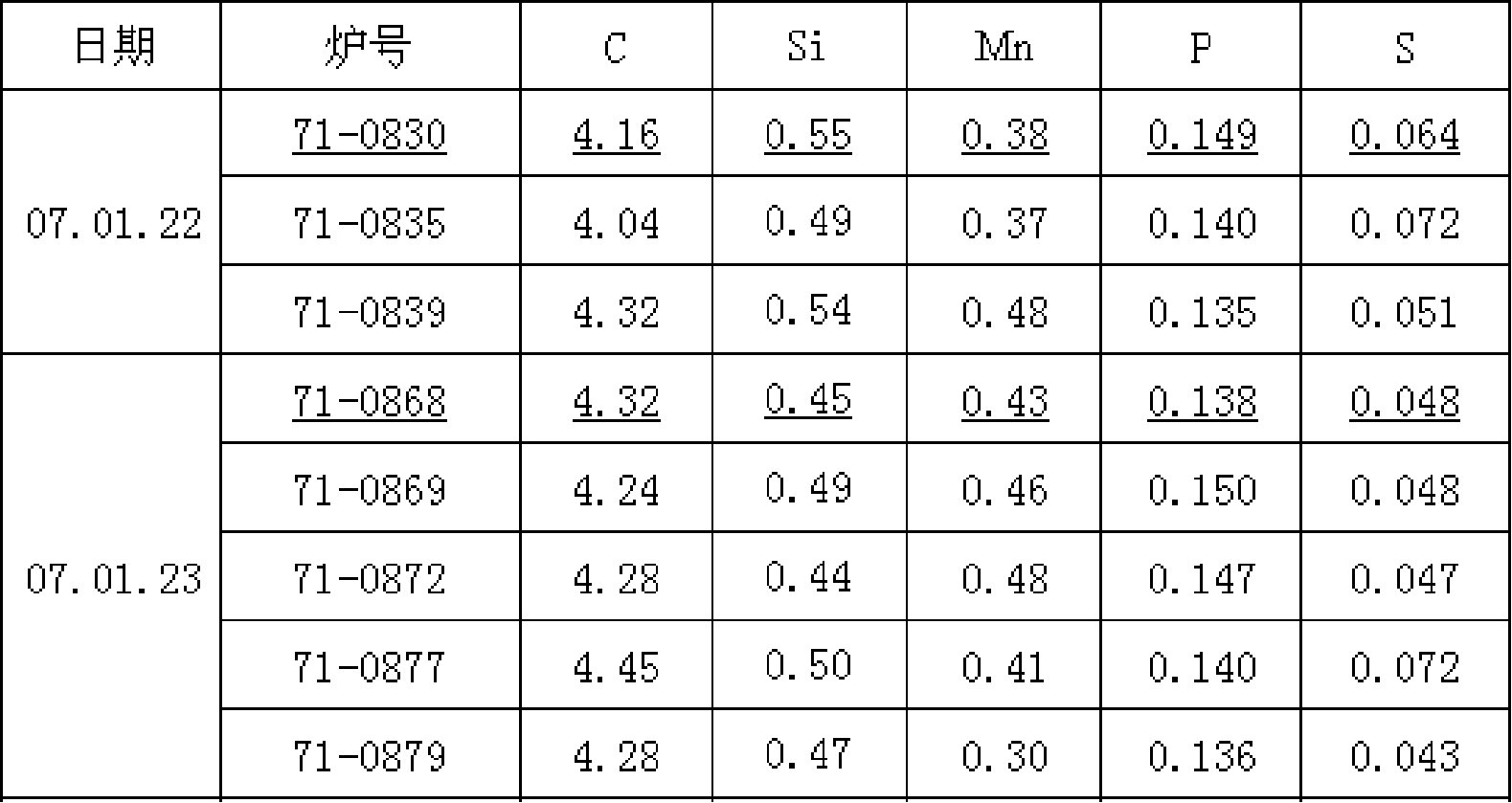

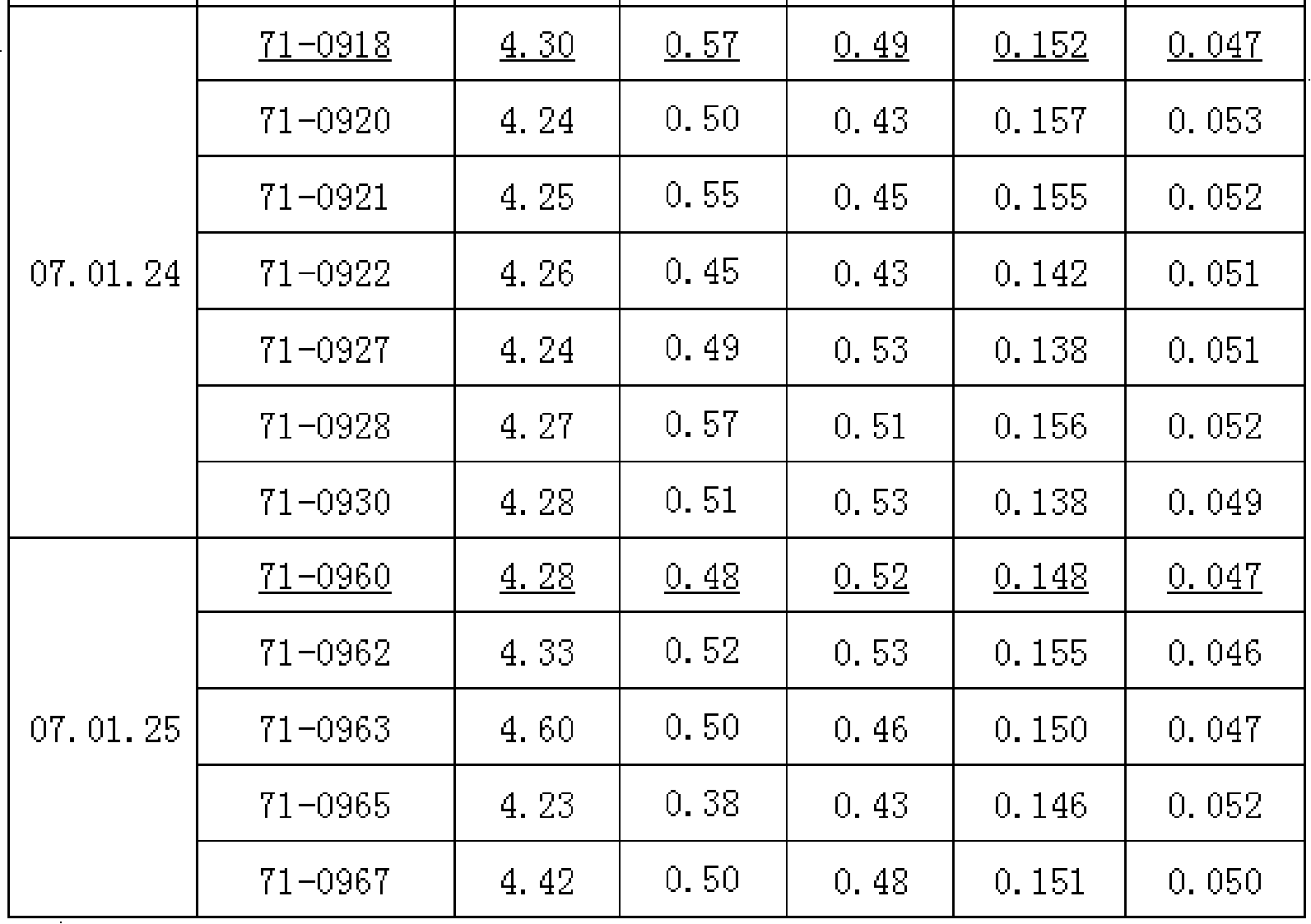

Image

Examples

Embodiment Construction

[0013] The auxiliary material for slagging material of the present invention is characterized in that it is composed of the following components by weight ratio: 8.0-9.5 parts of converter steel slag, 0.5-2.0 parts of additives; wherein, the additives are composed of the following components in weight percentage Composition: Na 2 CO 3 5.00~10.00%, FeO 70.00~80.00%, BaCO 3 10.00~20.00%; the prepared slagging material contains the following components in weight percentage: CaO 32.00~45.00%, FeO 20.00~30.00%, BaCO 3 1.00~4.00%, SiO 2 7.00~12.00%, MgO 7.00~9.00%, Na 2 COx 0.5-2.00%.

[0014] Na in the additive of the present invention 2 CO 3 、BaCO 3 It has the function of dephosphorization, FeO provides oxygen sites, and also has the function of dephosphorization. The additive used in the present invention can comprehensively play the functions of dephosphorization and slagging, and is a new high-quality auxiliary material for slagging materials.

[0015] The slagging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com