Method and device for on-line catalytic pyrolysis fine purification of biomass

A technology of catalytic cracking and biomass oil, which is applied in catalytic cracking, cracking, petroleum industry, etc., can solve the problems of affecting fast cracking reaction, reducing liquid yield, reducing liquid yield, etc., and achieves the effect of weakening pyrolysis and condensation reaction Impact, reduce energy consumption and investment and operation costs, and improve the effect of liquid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

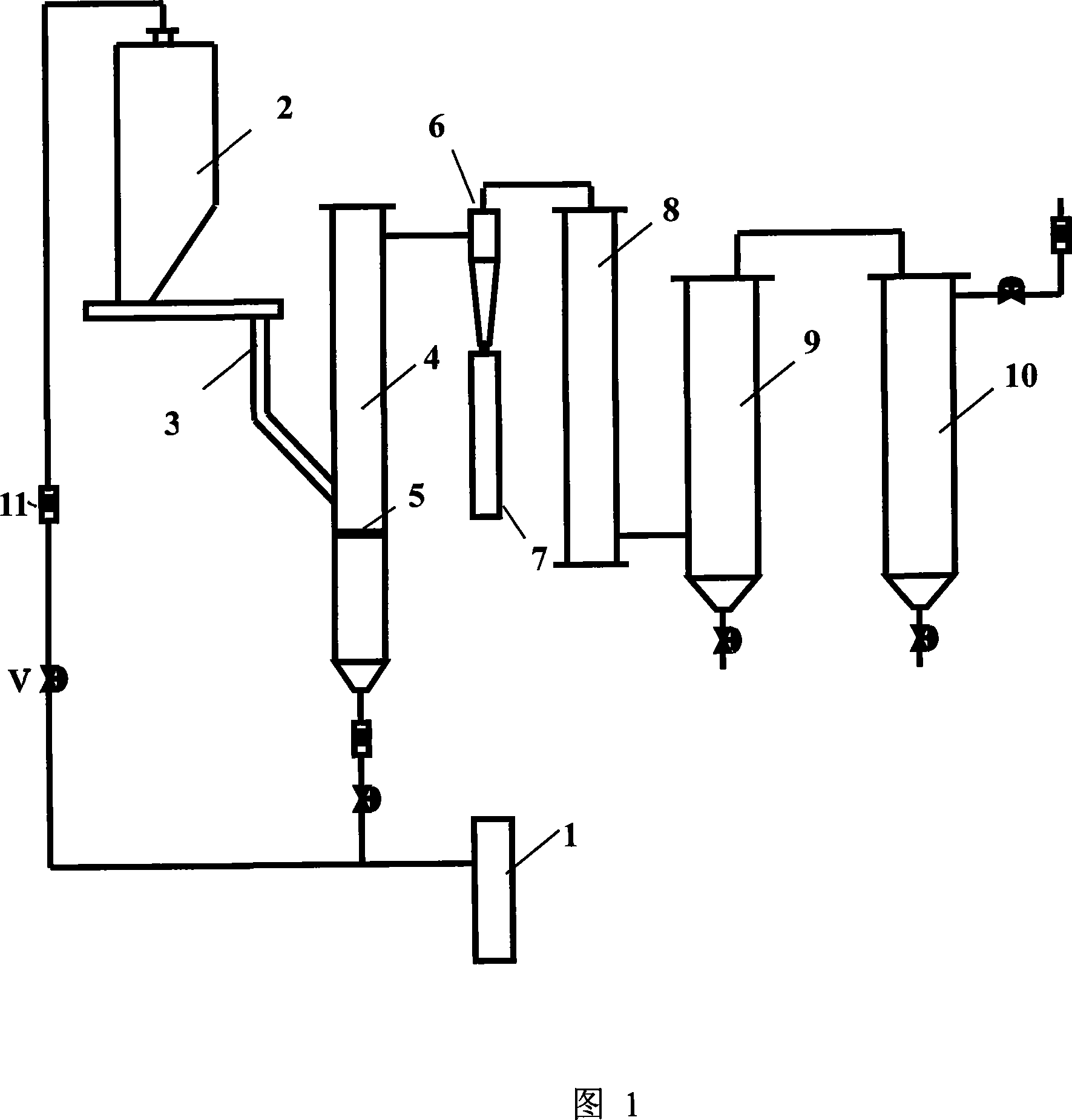

[0026]See Fig. 1, the device for refining biomass oil on-line catalytic cracking of the present invention comprises a hopper 2 connected in sequence, a screw feeder 3, an atmospheric pressure bubbling fluidized bed gasifier 4, a cyclone separator 6, a downward fixed atmospheric pressure bed reactor 8, a primary condenser 9 and a secondary condenser 10, and a nitrogen cylinder 1 connected to the top of the hopper 2 and the bottom of the normal pressure bubbling fluidized bed gasifier 4; wherein the normal pressure bubbling fluidized bed A gas distribution plate 5 is also provided at the middle and lower part of the gasifier 4, and an ash hopper 7 is provided below the cyclone separator 6. In addition, a gas flow meter 11 with a regulating valve is provided on the passage connecting the nitrogen cylinder 1 with the hopper 2 and the atmospheric pressure bubbling fluidized bed gasifier 4, and on the exhaust pipeline at the rear end of the second condenser 10 , so as to control the...

Embodiment 6~10

[0041] Fix the catalytic cracking temperature at 500°C and change the mass space velocity from 0.5 to 7.0h -1 , other process conditions are consistent with Embodiment 1~5.

[0042] The fast cleavage product yield is consistent with Examples 1-5.

[0043] The product yield after online catalytic cracking, and its conversion into yield using bio-oil as raw material are shown in Table 4.

[0044] Table 4. The effect of space velocity on the yield of online catalytic cracking products

[0045] implement

[0046] It can be seen that the liquid yield of the present invention is obviously higher than that of off-line catalytic cracking, and the coking rate is also significantly lower than that of off-line catalytic cracking.

[0047] The biomass oil under the condition of the highest liquid yield in the above examples was analyzed for hydrocarbon elements, and the oxygen content was calculated by the subtraction method, and the results are shown in Table 5. It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com