Powder for black zirconia sintered body, production method thereof, and sintered body thereof

A black zirconia, sintered body technology, applied in chemical instruments and methods, inorganic chemistry, zirconium compounds, etc., can solve problems such as reducing the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

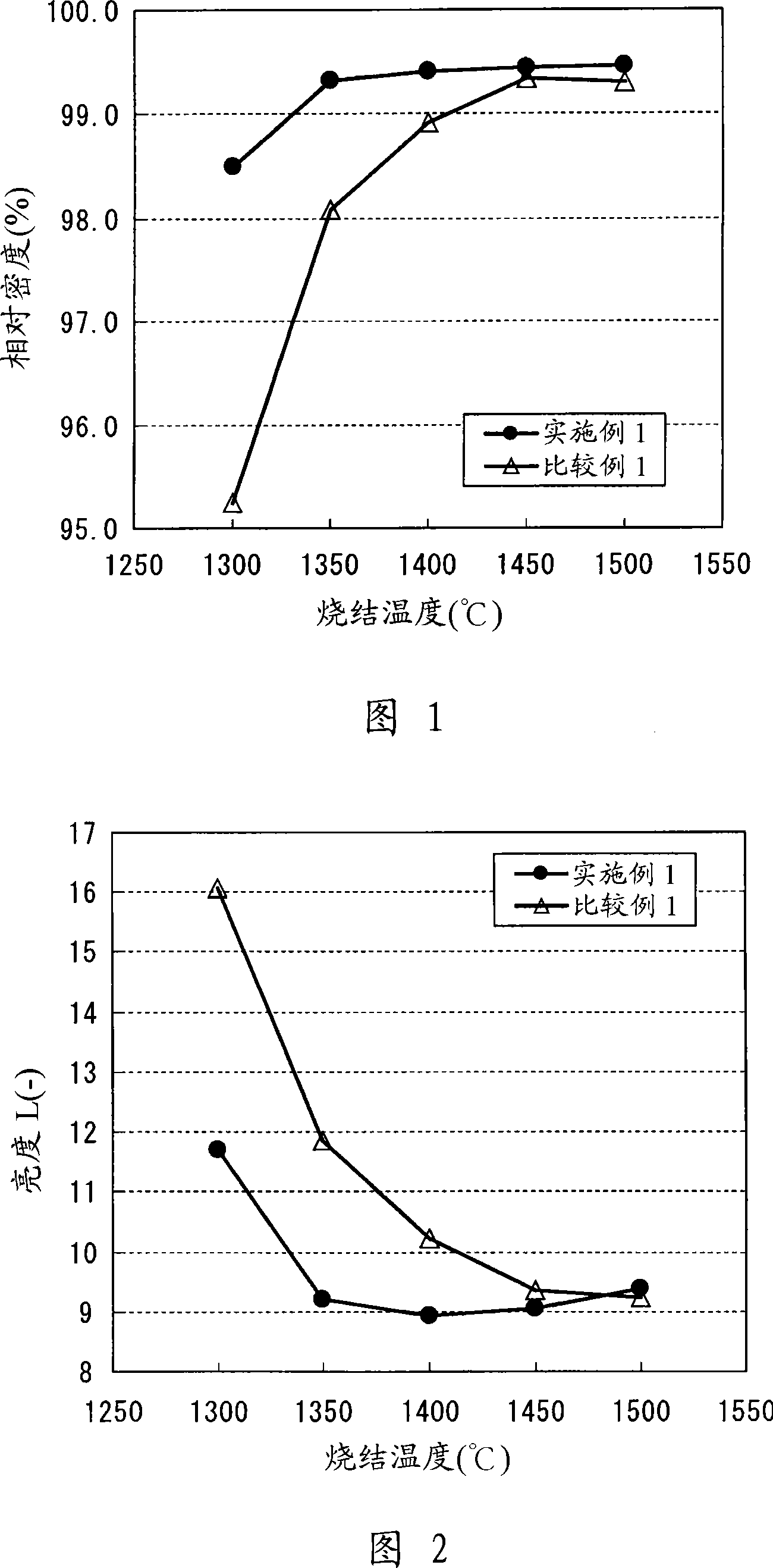

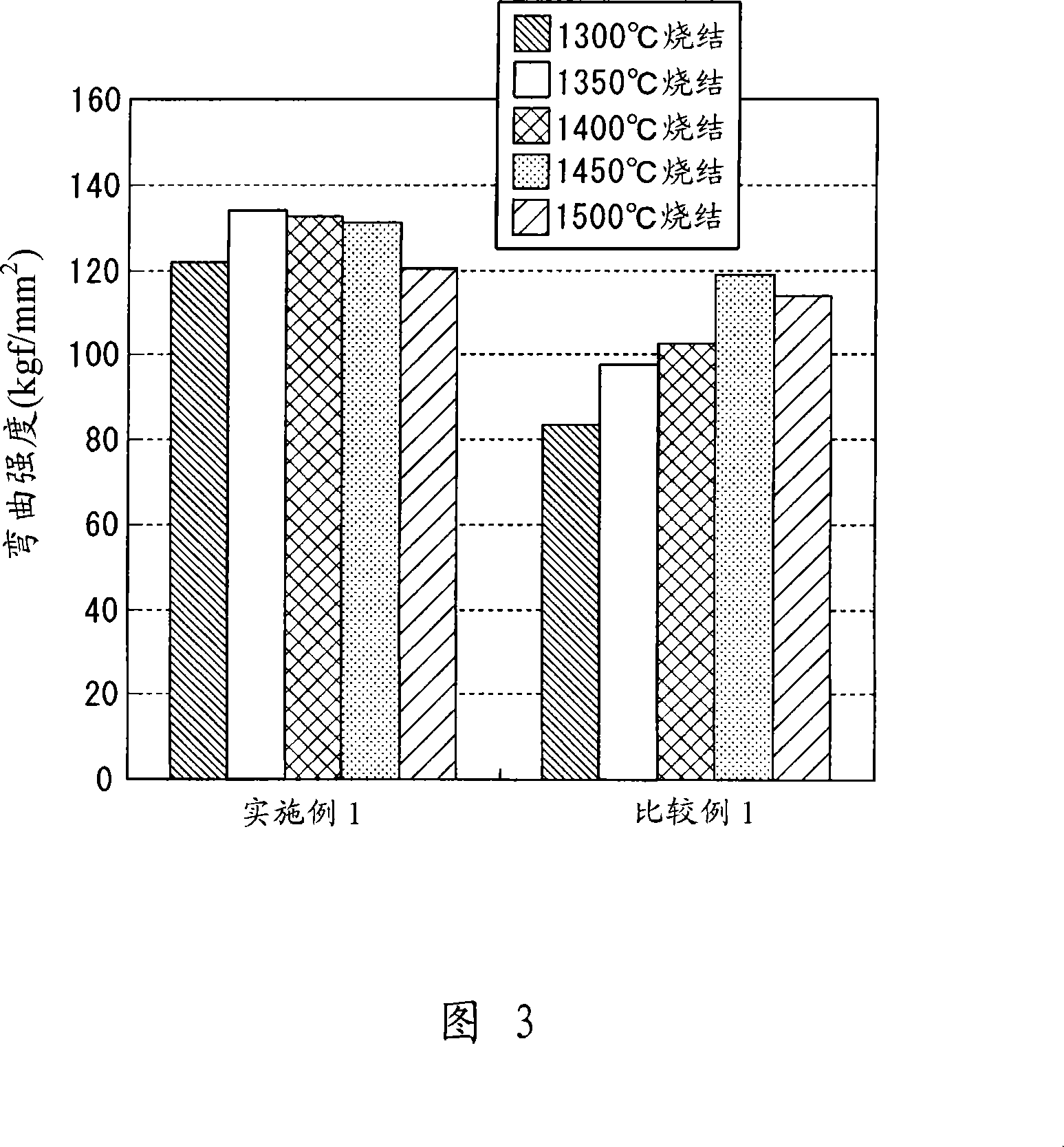

Embodiment 1

[0066] Zirconia powder TZ-3YS-E manufactured by Tosoh Co., Ltd. at 96.0% by weight (except for Y with 5.35% by weight) 2 o 3 Contains 0.25% by weight of Al in addition to stabilized zirconia 2 o 3 , BET specific surface area is 6m 2 In / g), the coprecipitate obtained by adding ammonia water to the aqueous nitrate solution of Co, Zn, Fe, and Al was filtered, washed with water, and dried as a colorant using 3.5% by weight of coprecipitate, and an additional 0.5% by weight was added. Al 2 o 3 The powder is wet-mixed with a ball mill and then dried to obtain a mixed powder.

[0067] Through uniaxial molding pressure 700kg / cm 2 The obtained mixed powder was molded to obtain a composite molded body. The sintering temperature of each molded body is in the range of 1300 ° C ~ 1500 ° C, set a temperature every 50 ° C, using an electric furnace, in the atmosphere, under the condition of a heating rate of 100 ° C / hour, to reach the specified temperature, each The molded body wa...

Embodiment 2

[0072] In addition to adding 3.5 wt% of dry powder as a colorant, 1.0 wt% of commercially available Al 2 o 3 Except for the powder, it was sintered for 2 hours under the same conditions as in Example 1.

[0073] In addition, when the dry powder was separately fired at 800°C, it was confirmed that the chemical composition was (Co 0.68 Zn 0.32 )(Fe 0.70 al 0.30 ) 2 o 4 .

[0074] Table 1 shows the performance evaluation results of the obtained sintered body.

Embodiment 3

[0076] Sintering was carried out for 2 hours under the same conditions as in Example 1 except that 3.5% by weight of dry powder was added as a colorant.

[0077] In addition, when the dry powder was separately fired at 800°C, it was confirmed that the chemical composition was Co(Fe 0.50 al 0.50 ) 2 o 4 .

[0078] Table 1 shows the performance evaluation results of the obtained sintered body.

[0079] Due to the absence of Zn, the generated pores increase and the bending strength decreases, but a certain degree of bending strength, brightness, and sintering uniformity can also be maintained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com