Ship with liquid transport tanks provided with deformation absorbers

An absorber, a technology for transporting liquids, applied in the directions of transportation and packaging, some cabins in the hull, the hull, etc., which can solve the problems of needing maintenance, fragile elastic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

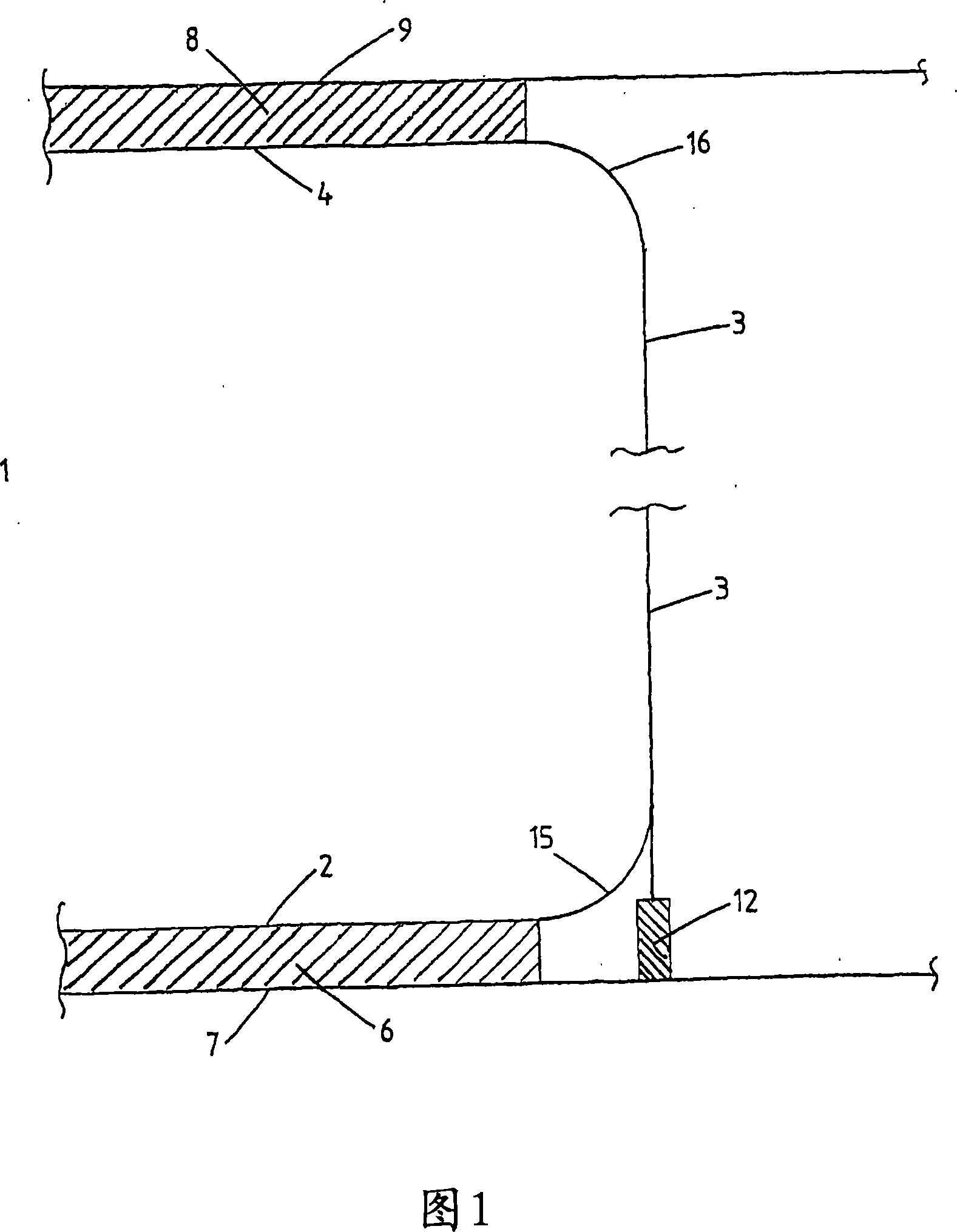

[0039] In FIG. 1 , reference numeral 1 generally designates a transport tank. The transport tank 1 consists of a tank bottom 2 , a cylindrical tank peripheral wall 3 and a tank top 4 . The tank bottom 2 is designed flat and is connected to the lower deck 7 of the hull, which is not shown in further detail, by inserting an insulating layer 6 . The top 4 of the tank is connected to the upper deck 9 of the hull by inserting an insulating layer 8 . The tank circumferential wall 3 is partially supported towards the bottom by deformable support means 12 . The support means 12 engages on the bottom part of the tank peripheral wall 3 . Deformation absorbers 15, 16 are accommodated in the tank walls. Here the deformation absorbers 15, 16 are formed as segments with a cross-section in the shape of a sector (quarter circle shape) and are respectively between the tank bottom 2 and the tank peripheral wall 3, or between the tank top 4 and the tank peripheral wall 3 extend between. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com