Condensation polymer type organic silicon die plastic and preparation technique of organic silicon resin for the same

A preparation process and silicone technology are applied in the field of preparation technology of polycondensation-type silicone molding compounds and special silicone resins, which can solve the problems of high thermal shrinkage, poor adhesion, and low softening point, and improve the environment. , the effect of reducing the reaction speed and improving the compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

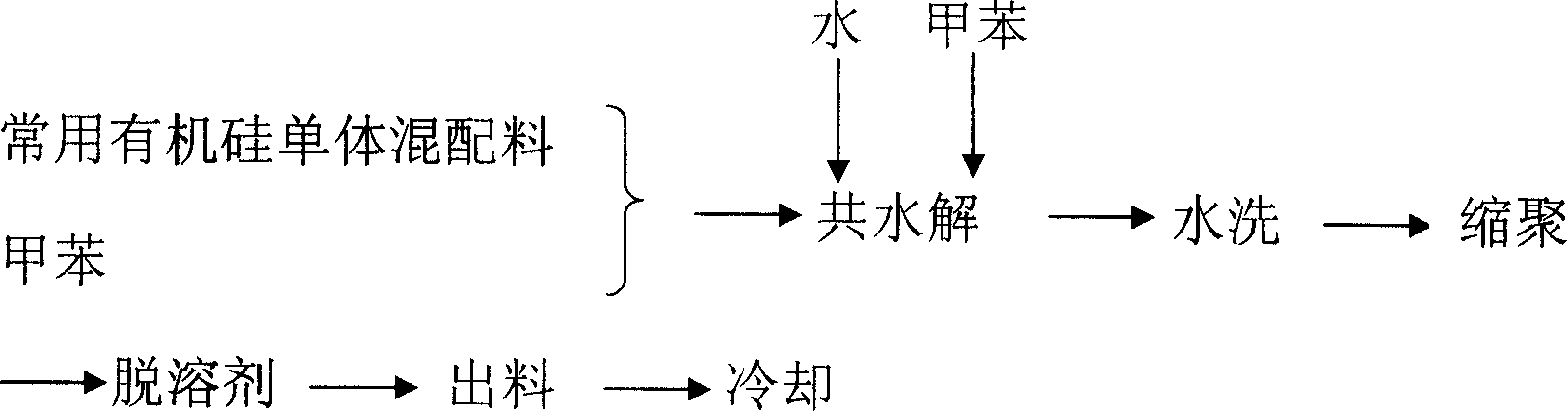

Method used

Image

Examples

Embodiment 1

[0024] a. Raw material composition ratio by mass

[0025] Monomethyltrichlorosilane Purity>99% 60 parts

[0026] Dimethyldichlorosilane 99.9% purity 60 parts

[0027] One-phenyltrichlorosilane Purity>99% 120 parts

[0028] Ester functional silicone coupling agent purity >99% 90 parts

[0029] b. After fully mixing the above-mentioned organosilicon monomers, add 800 parts of toluene, 1000 parts of water, and 360 parts of ethylene glycol butyl ether solvent, co-hydrolyze at a temperature of 10°C, wash with water, and add 400 parts of dihydroxydiol Phenylsilane is used as a modifier, 1.8 parts of cobalt naphthenate is used as a catalyst for polycondensation, and finally the product is obtained by desolvating under the condition of a vacuum of 1kpa, cooling and pressing into tablets.

[0030] The performance of the obtained product is suitable for molding plastics, with good heat resistance and arc resistance, but slightly higher thermal elasticity and larger expansion coeffici...

Embodiment 2

[0032] a. Raw material composition ratio by mass

[0033] Monomethyltrichlorosilane Purity>99% 120 parts

[0034] Dimethyldichlorosilane 99.9% purity 60 parts

[0035] One-phenyltrichlorosilane Purity>99% 180 parts

[0036] Diphenyldichlorosilane purity>99% 60 parts

[0037] Organosilicon monomer containing double bonds, purity > 99%, 40 parts

[0038] Acryloyl silicone macromonomer Purity>99% 160 parts

[0039] b. After fully mixing the above silicone monomers, add 1200 parts of toluene, 1800 parts of water, and 600 parts of methyl ethyl ketone solvent, co-hydrolyze at a temperature of 10°C, wash with water, and add 660 parts of bisphenol A modified silicone The oligomer is used as a modifier, and 6 parts of cobalt naphthenate is used as a catalyst for polycondensation, and finally the product is obtained by desolventizing under the condition of a vacuum of 1kpa, cooling and pressing into tablets.

[0040] The performance of the obtained product is quite good, but the cu...

Embodiment 3

[0042] a. Raw material composition ratio by mass

[0043] Monomethyltrichlorosilane Purity>99% 120 parts

[0044] Dimethyldichlorosilane 99.9% purity 60 parts

[0045] One-phenyltrichlorosilane Purity>99% 120 parts

[0046] Diphenyldichlorosilane purity>99% 60 parts

[0047] Ester functional silicone coupling agent purity >99% 100 parts

[0048]b. After fully mixing the above silicone monomers, add 800 parts of toluene, 1100 parts of water, and 500 parts of methyl ethyl ketone solvent, co-hydrolyze at a temperature of 10°C, wash with water, and add 460 parts of bisphenol A modified silicone The oligomer is used as a modifier, and 2.3 parts of cobalt naphthenate is used as a catalyst for polycondensation, and finally the product is obtained by desolventizing under the condition of a vacuum of 1kpa, cooling and pressing into tablets.

[0049] The obtained product has good performance and is suitable for making molding compounds, but it is slightly soft at room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com