Method of double filum narrow interstice alternating-direct current pulse matching electric arc welding

A DC pulse, narrow-gap technology, used in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problem of not seeing the arc effect, and achieve the effect of solving the problem of side wall fusion, easy maintenance, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In the test of the present invention, the main equipment adopted is: one DC electric welding machine, one AC electric welding machine, two wire feeders, one double wire AC and DC welding controller, and several welding wires.

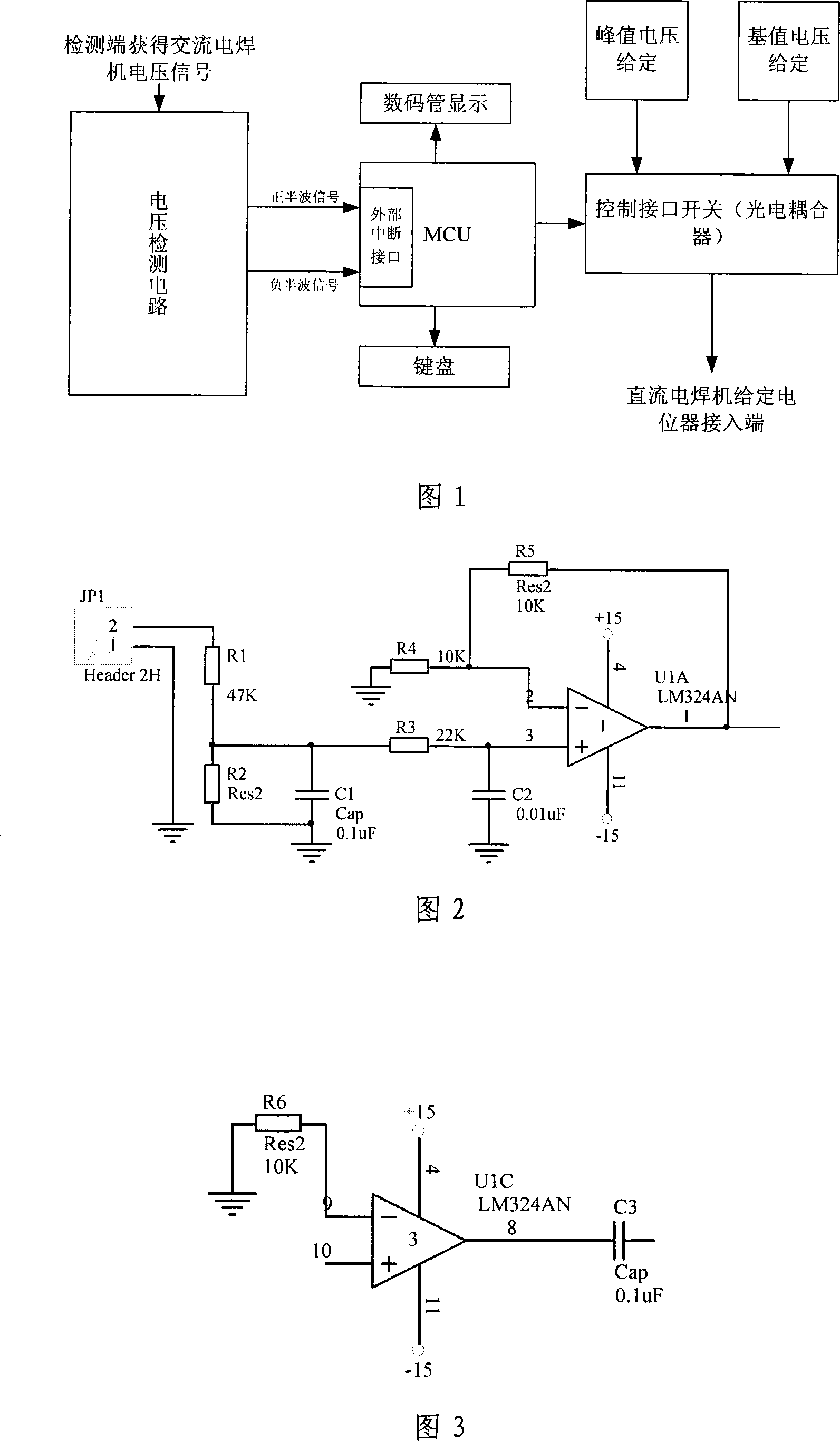

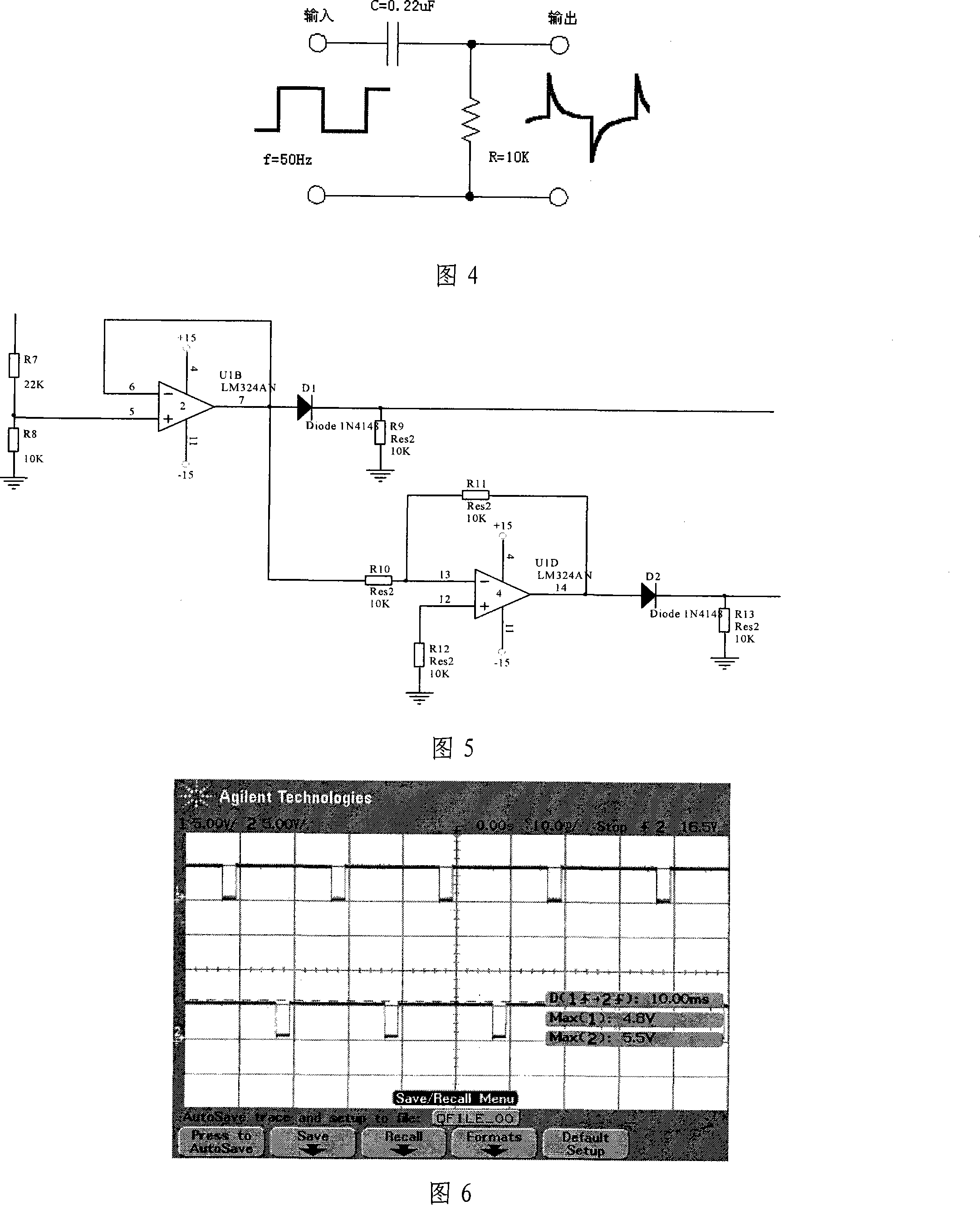

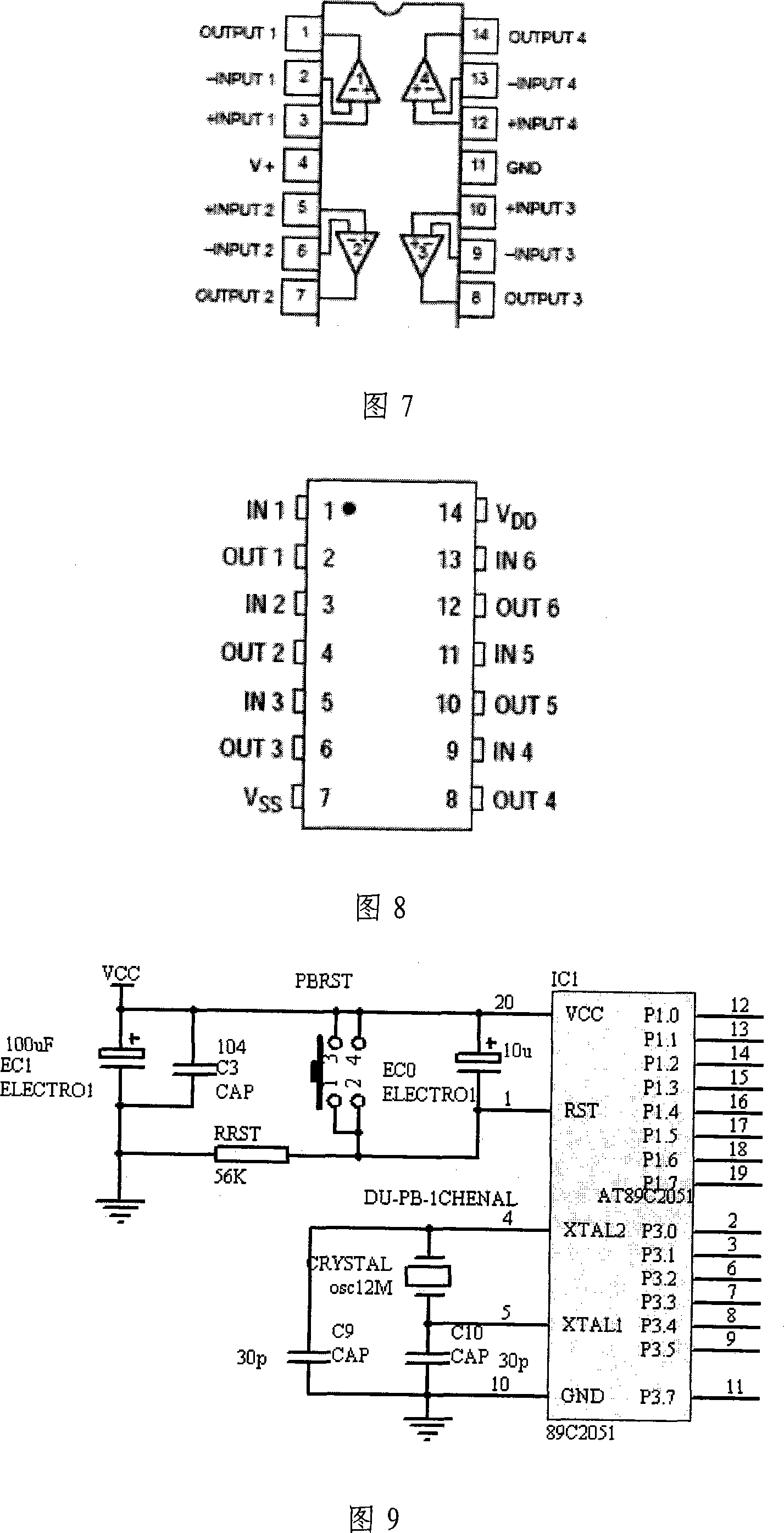

[0042] The controller adopts a modular design and is divided into two modules, namely the AC detection module, hereinafter referred to as the detection module, and the DC welding machine pulse control module, hereinafter referred to as the control module. The detection module adopts an analog circuit-based design method. The module adopts the digital structure with MCU single-chip microcomputer as the core, and has 3 working modes in total, which can respectively make the welding power supply operate in constant peak voltage mode (mode1), constant base voltage mode (mode2), peak-base value pulse voltage mode (mode3) ) output, which can be flexibly selected in actual operation. The entire controller adopts the "black box" mode, the interface is si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com