Water filter materials comprising a mixture of microporous and mesoporous carbon particles and water filters with said filter materials

A filter material and filter technology, applied in the direction of filtration and separation, alkali metal compounds, adsorption water/sewage treatment, etc., can solve problems such as multi-space and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

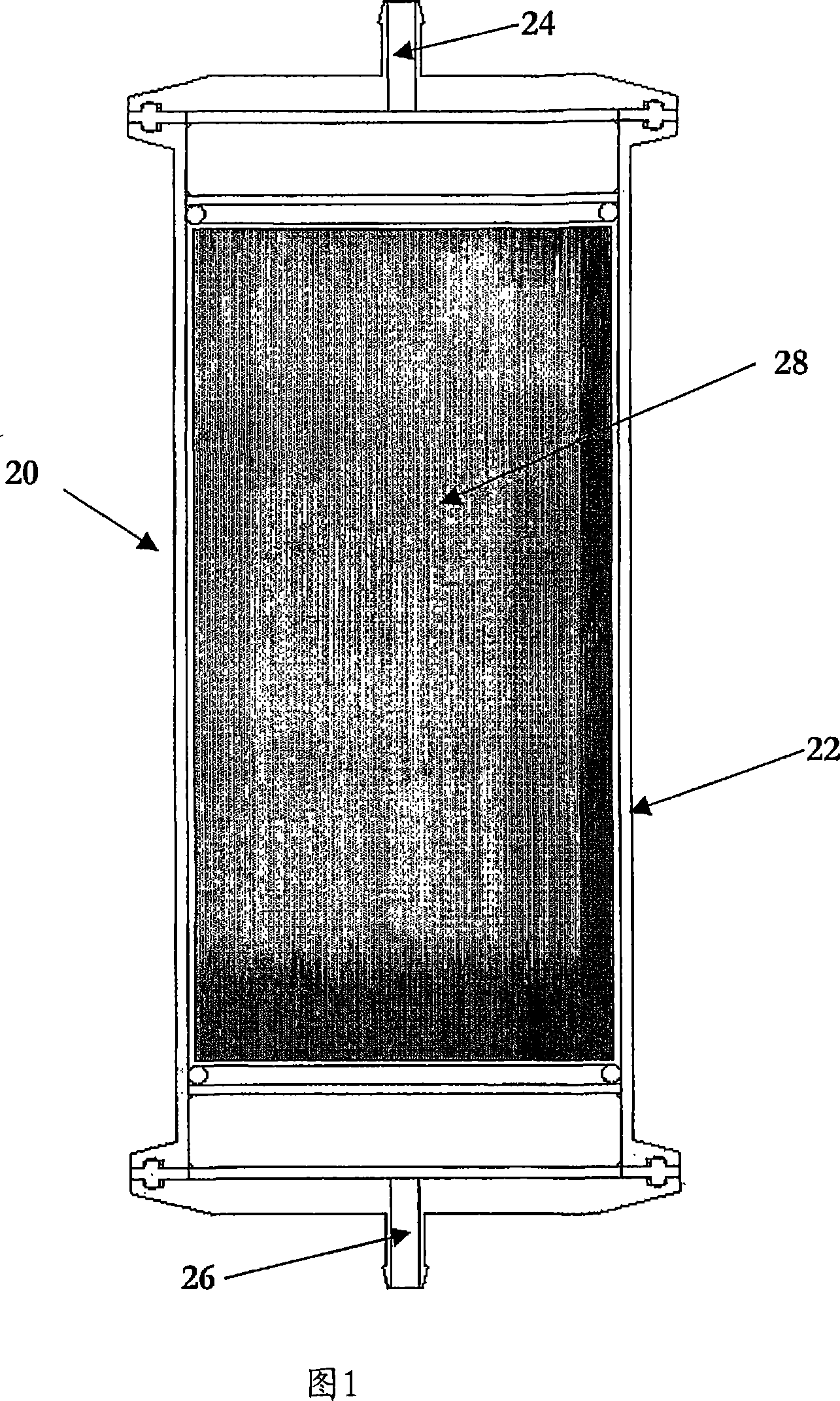

Image

Examples

Embodiment 1

[0131] Filters containing microporous and mesoporous activated carbon particles

[0132] About 5.5 g of microporous coconut shell carbon supplied by Barnebey Sutcliffe was mixed with 13.0 g of Nuchar® from MeadWestvaco Corp. (Covington, VA). RGC mesoporous alkaline activated carbon powder (D V,0.5 equal to about 45 μm) and then mixed with about 7 g of Microthene from Equistar Chemicals, Inc. (Cincinnati, OH) Low density polyethylene (LDPE) FN510-00 binder and about 2 g of Alusil from Selecto, Inc. (Norcross, GA) 70 Aluminosilicate powder mix. Prior to mixing, the mesoporous activated carbon particles were coated with polydiallyldimethylammonium chloride (polyDADMAC), and the coating was dried. The mixed powder was then poured into a circular aluminum mold having an inner diameter of about 7.62 cm (about 3 inches) and a depth of about 1.27 cm (about 0.5 in.). The mold was closed and placed in a thermoformer with a platen at 204°C for 1 hour. The mold was then allow...

Embodiment 2

[0134] Filters containing microporous and mesoporous activated carbon particles

[0135] Approximately 13.0 g of microporous coconut shell carbon supplied by Barnebey Sutcliffe and 13.0 g of mesoporous alkaline activated carbon powder (D V,0.5 equal to about 92 μm) and then mixed with about 7 g of Microthene from Equistar Chemicals, Inc. (Cincinnati, OH) Low density polyethylene (LDPE) FN510-00 binder and about 2 g of Alusil from Selecto, Inc. (Norcross, GA) 70 Aluminosilicate powder mix. Prior to mixing, the mesoporous activated carbon particles were coated with polydiallyldimethylammonium chloride (polyDADMAC), and the coating was dried. The mixed powder was then poured into a circular aluminum mold having an inner diameter of about 7.62 cm (about 3 inches) and a depth of about 1.27 cm (about 0.5 inches). The mold was closed and placed in a thermoformer with a platen at 204°C for 1 hour. The mold was then allowed to cool to room temperature, opened, and the axial f...

Embodiment 3

[0137] Removal of TTHM, viruses and bacteria by filters containing microporous and mesoporous activated carbon particles

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com