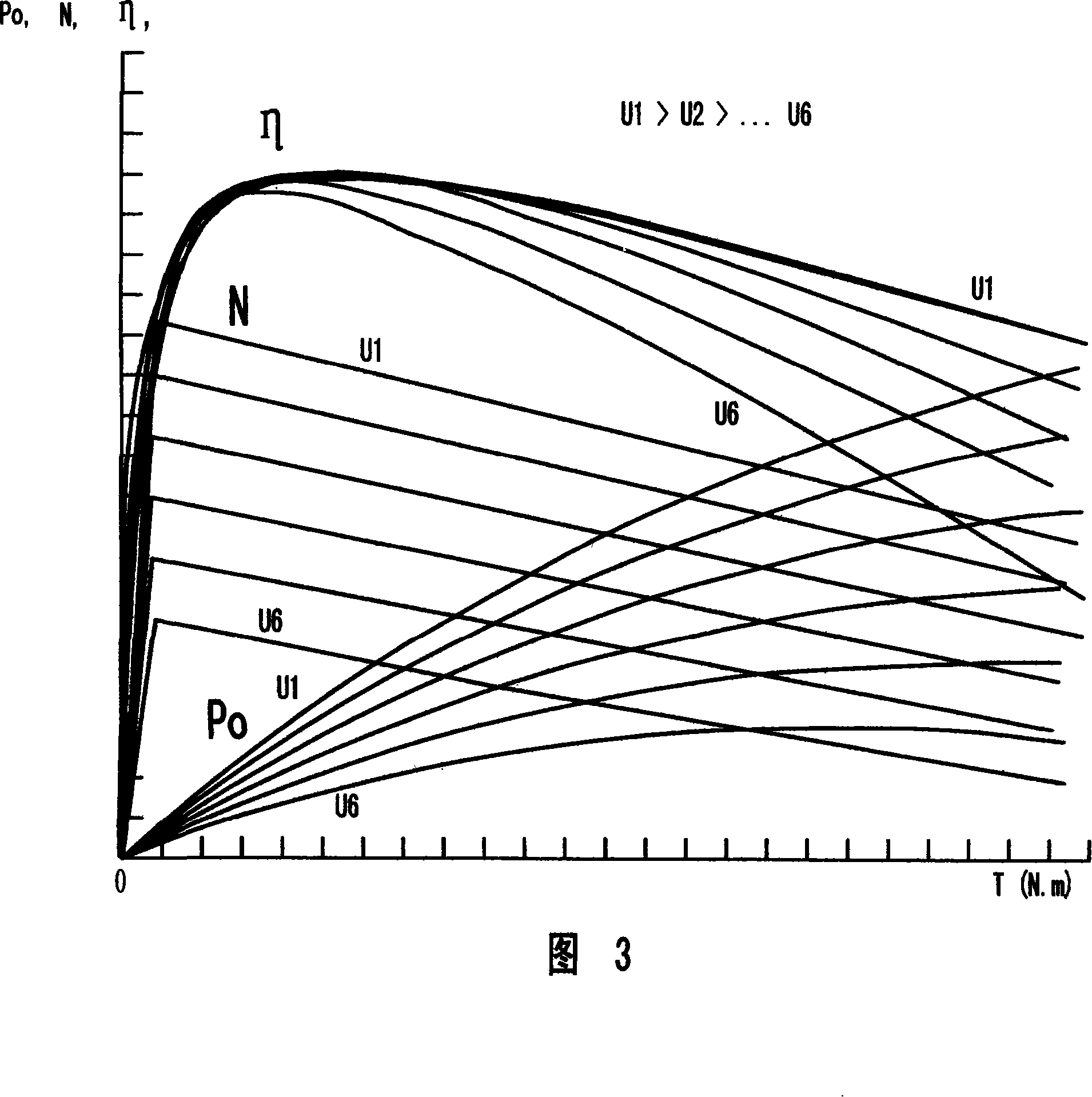

Permanent-magnet DC motor drive control system with approximate constant power pulling motor characteristics

A technology for motor drive control and traction motor, which is applied in the direction of speed/torque control of a single motor, electric components, and mechanical energy control, and can solve the problems of complex motor structure, reduced reliability, and poor control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Since each partial component that constitutes the present invention has mature technologies, especially permanent magnet direct current brushed or brushless motors and their drive control technology, DC-DC converter technology, there is no fundamental difficulty in the implementation of the present invention.

[0048] Figure 1 shows a DC permanent magnet brushless motor drive control system with approximately constant power traction motor characteristics.

[0049] In Figure 1: 1 is a rechargeable battery or supercapacitor pack E / C, 2 is a bidirectional buck-boost controllable DC-DC converter, 3 is a motor PWM drive controller, and 4 is a permanent magnet brushless DC motor (BLDCM) , 5 is the speed sensor, 6 is the Un-U'n function converter that converts the output signal Un of the speed sensor into the control signal U'n of the output voltage of the bidirectional buck-boost controllable DC-DC converter, and 7 is the PWM pulse generation and drive controller.

[0050] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com