AIN/Si*N* nanometer multi-layer horniness coatings as well as its preparing method

A nano-multilayer, hard coating technology, applied in the direction of coating, metal material coating process, layered products, etc., can solve the problem of low deposition efficiency of ceramic targets, long time required, and inability to use nano-multilayer coating. Industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

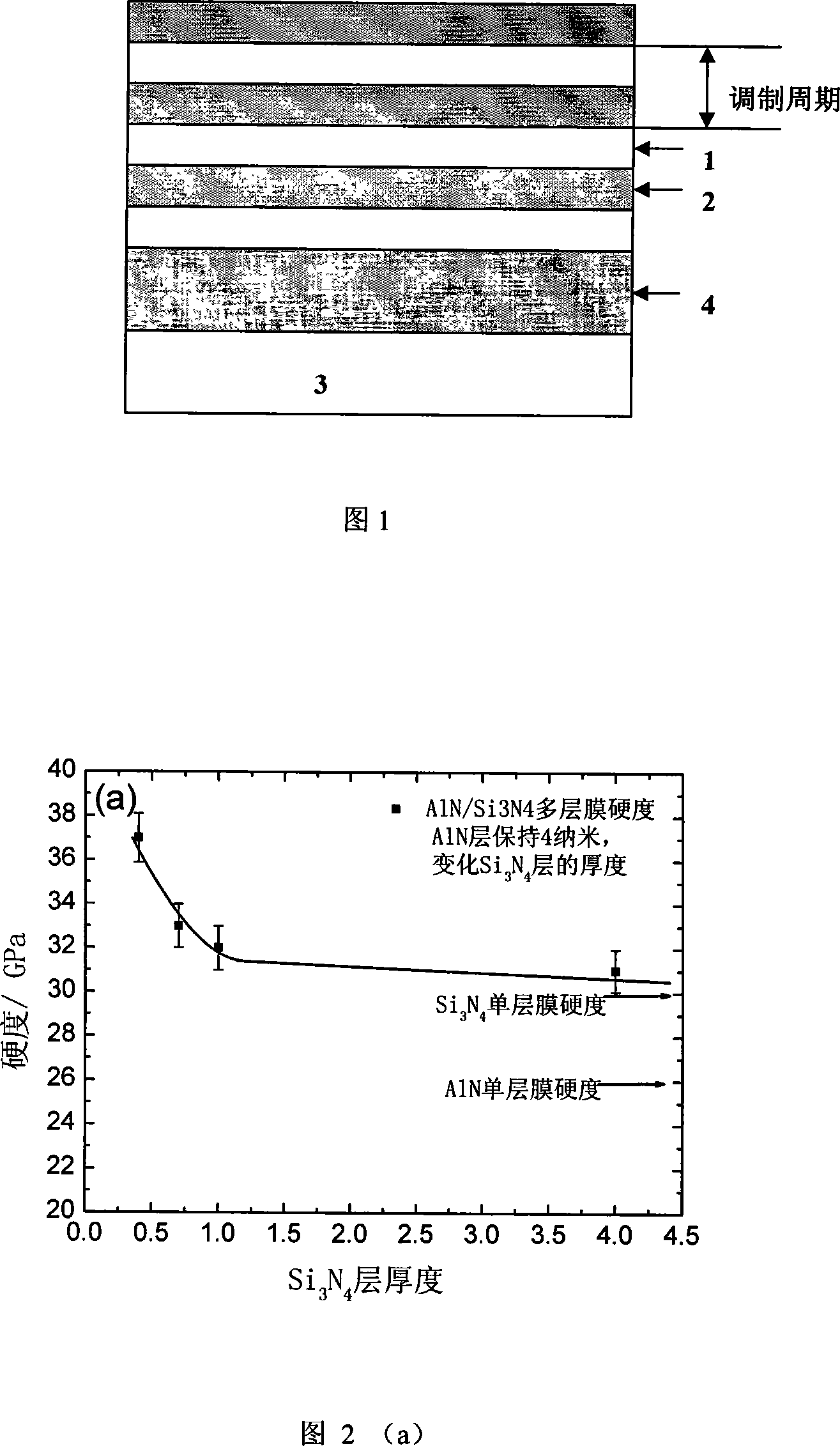

Method used

Image

Examples

example 1

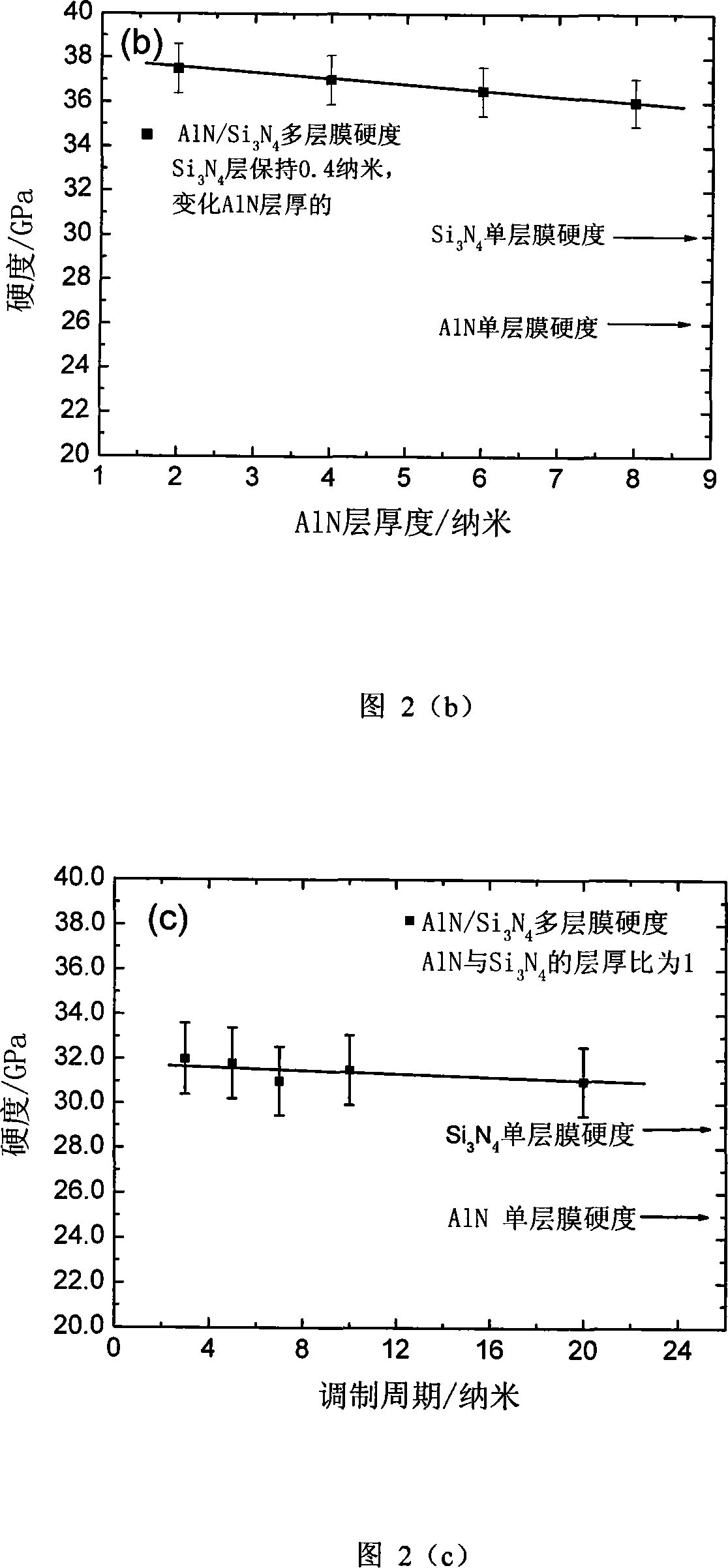

[0033] AlN / Si of the present invention 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is Ar: gas flow is 10 sccm, N 2 The gas partial pressure is 3sccm. The Al target sputtering power is 100W, the deposition time is 33 seconds, the Si target sputtering power is 100W, the deposition time is 4 seconds, and the substrate temperature is 500°C. The resulting AlN / Si 3 N 4 The thickness of the AlN layer in the multilayer coating is 4 nm, Si 3 N 4 The layer thickness is 0.4 nm, and the hardness of the coating is 37.8 GPa.

example 2

[0035] AlN / Si of the present invention 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas flow rate is 10sccm, N 2 The gas partial pressure is 3 sccm. The Al target sputtering power is 100W, the deposition time is 33 seconds, the Si target sputtering power is 100W, the deposition time is 6 seconds, and the substrate temperature is 500°C. The resulting AlN / Si 3 N 4 The thickness of the AlN layer in the multilayer coating is 4 nm, Si 3 N 4 The layer thickness is 0.7 nm, and the hardness of the coating is 33 GPa.

example 3

[0037] AlN / Si of the present invention 3 N 4 The concrete process parameter of the preparation method of multi-layer coating is: Ar gas flow rate is 4sccm, N 2 The gas partial pressure is 2 sccm. The Al target sputtering power is 100W, the deposition time is 24 seconds, the Si target sputtering power is 100W, the deposition time is 70 seconds, and the substrate temperature is 500°C. The resulting AlN / Si 3 N 4 The thickness of the AlN layer in the multilayer coating is 2.5nm, Si 3 N 4 The layer thickness is 7.5 nm and the hardness of the coating is 33 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com