Circular saw blade profile centerless grinding machine and method for centerless grinding circular saw blade profile

A centerless grinding machine and circular saw blade technology, which is applied to the field of centerless grinding machines on the side of circular saw blades, can solve the problems of low processing efficiency, high energy consumption, and large investment in grinding machine equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

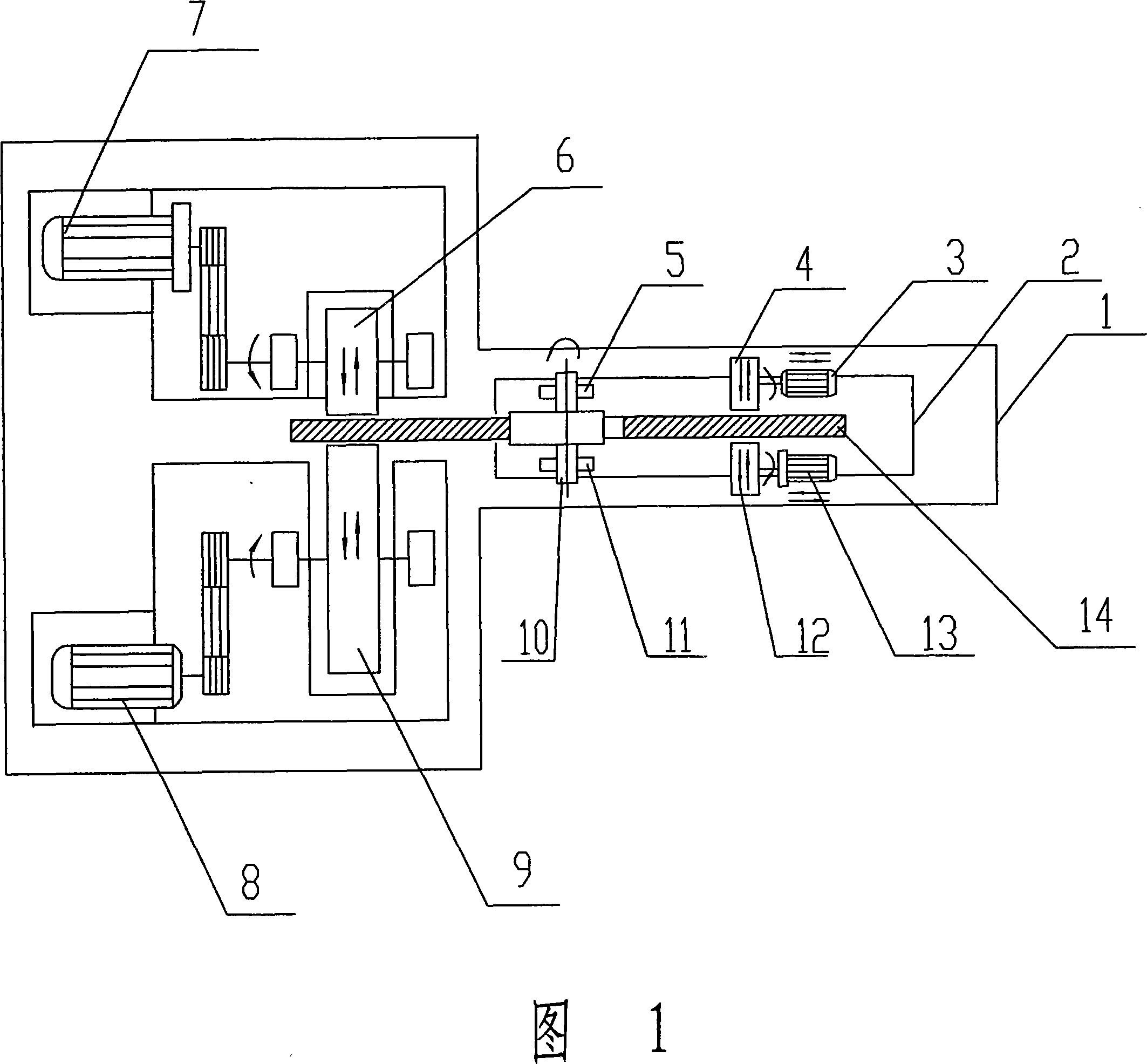

[0017] The present invention is described in detail below in conjunction with accompanying drawing:

[0018] The circular saw blade side centerless grinder of the present invention consists of a machine base 1, a working table 2, motors 3 and 13, driving wheels 4 and 12, saw blade supports 5 and 11, back wheels 6, back wheel motors 7, and grinding wheel motors 8 , Grinding wheel 9, mandrel 10 constitutes, and the saw blade feed table surface 2 that can move left and right is equipped with on one side of support 1 top, can make saw blade 14 complete feed and retreat operation. Saw blade supports 5 and 11 are fixed on the workbench 2, mandrel 10 is housed on the saw blade supports 5 and 11, saw blade 14 is suspended on the mandrel 7, and a certain gap is left on the mandrel 7 right-hand side to satisfy the emery wheel 9 And the back wheel 6 can be ground to the edge of the center hole of the saw blade 14; in order to make the saw blade 14 rotate at a steady speed in the grinding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com