A process equipment of magnesium alloy plate belt and technics

A magnesium alloy plate and processing equipment technology, which is applied in metal processing equipment, lighting and heating equipment, metal rolling, etc., can solve the problems that cannot meet the needs of industrial applications, and has not developed casting and rolling equipment for magnesium alloys. The effect of production process, reduction of production cost and improvement of product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

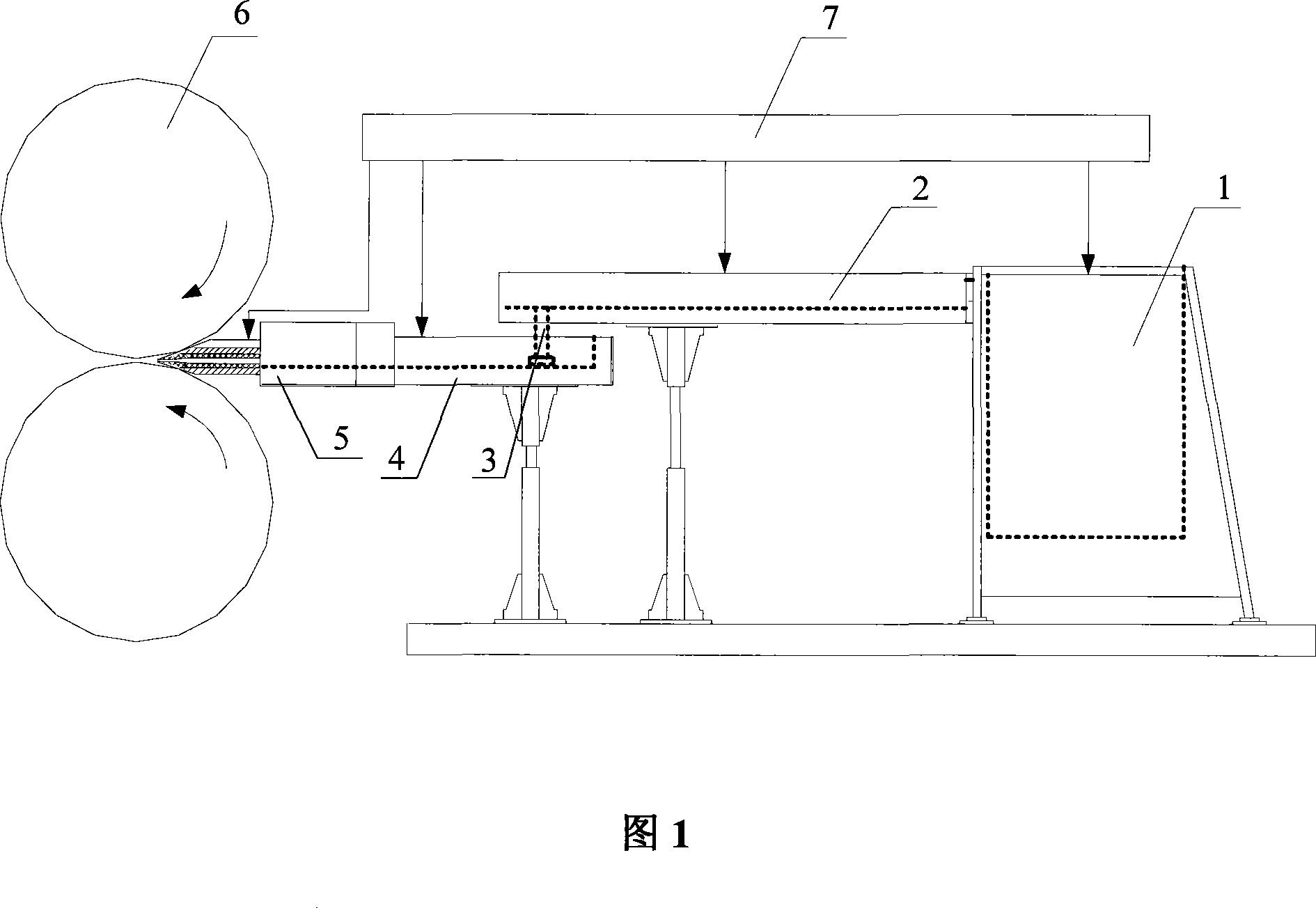

[0047] After the AZ31 magnesium alloy ingot is preheated, it is put into a 100kg resistance melting furnace 1, and when the temperature reaches 300°C, the mixed gas is fed through the mixed gas supply equipment to prevent the magnesium alloy melt from oxidizing and burning, and continue to heat up. When the temperature reaches 700°C, carry out stirring and refining, ventilate and blow slag, and let it stand for 10 minutes. Under the protective atmosphere, the magnesium alloy liquid is transported to the front box 4 through the launder 2, and the magnesium alloy liquid is kept at a constant temperature (600-800 °C) in the front box 4. ℃) and control the relatively constant liquid level height of the magnesium alloy liquid flowing into the casting roll, which is 4-6 cm higher than the center line. The magnesium alloy liquid enters the casting nozzle 5 at the same temperature, and the lip height of the liquid outlet end of the casting nozzle 5 is 2.5 mm. , the length of the castin...

Embodiment 2

[0049] After the AZ31 magnesium alloy ingot is preheated, it is put into a 500kg electric resistance melting furnace 1. When the temperature reaches 450-500°C, the mixed gas is fed into the mixed gas supply equipment to prevent the magnesium alloy melt from oxidizing and burning, and continue to heat up. When the temperature reaches 680°C, carry out stirring and refining, ventilate and blow slag, and let it stand for 20 minutes. Under the protective atmosphere, the magnesium alloy liquid is then transported to the front box 4 through the launder 2. The launder 2 and the front box 4 are sealed and vertical. placed, the front box is provided with a melt temperature and a float type liquid level controller 3 to maintain a constant temperature of the magnesium alloy liquid (600-800°C) and to control a relatively constant liquid level of the magnesium alloy liquid flowing into the casting roll. At the centerline 3-5cm, the magnesium alloy liquid enters the casting nozzle 5 at the sa...

Embodiment 3

[0051] After the AZ31 magnesium alloy ingot is preheated, it is put into a 1000kg resistance melting furnace 1. The material of the crucible is 5% to 20% manganese steel. 6 +CO 2 +The mixed gas of dry air is used for protection to prevent the magnesium alloy melt from oxidizing and burning, and to continue to heat up. When the temperature reaches 500°C, carry out stirring and refining, ventilate and blow slag and let it stand for 30 minutes. Under the protective atmosphere, the magnesium alloy liquid is then transported to the front box 4 through the launder 2. The launder and the front box are sealed and placed vertically up and down. In the front box, there are melt temperature and float type liquid level controllers 3 to keep the magnesium alloy liquid at a constant temperature (600-800°C) and to control the relatively constant liquid level of the magnesium alloy liquid flowing into the casting roll, which is higher than the center Line 2 ~ 4cm, magnesium alloy liquid ente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com