Shuttle

A shuttle and shuttle body technology, applied in shuttle, textile, textile and papermaking, etc., can solve the problems of poor impact ability, large deformation, short life and so on, and achieve the effect of long service life, low cost and easy production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

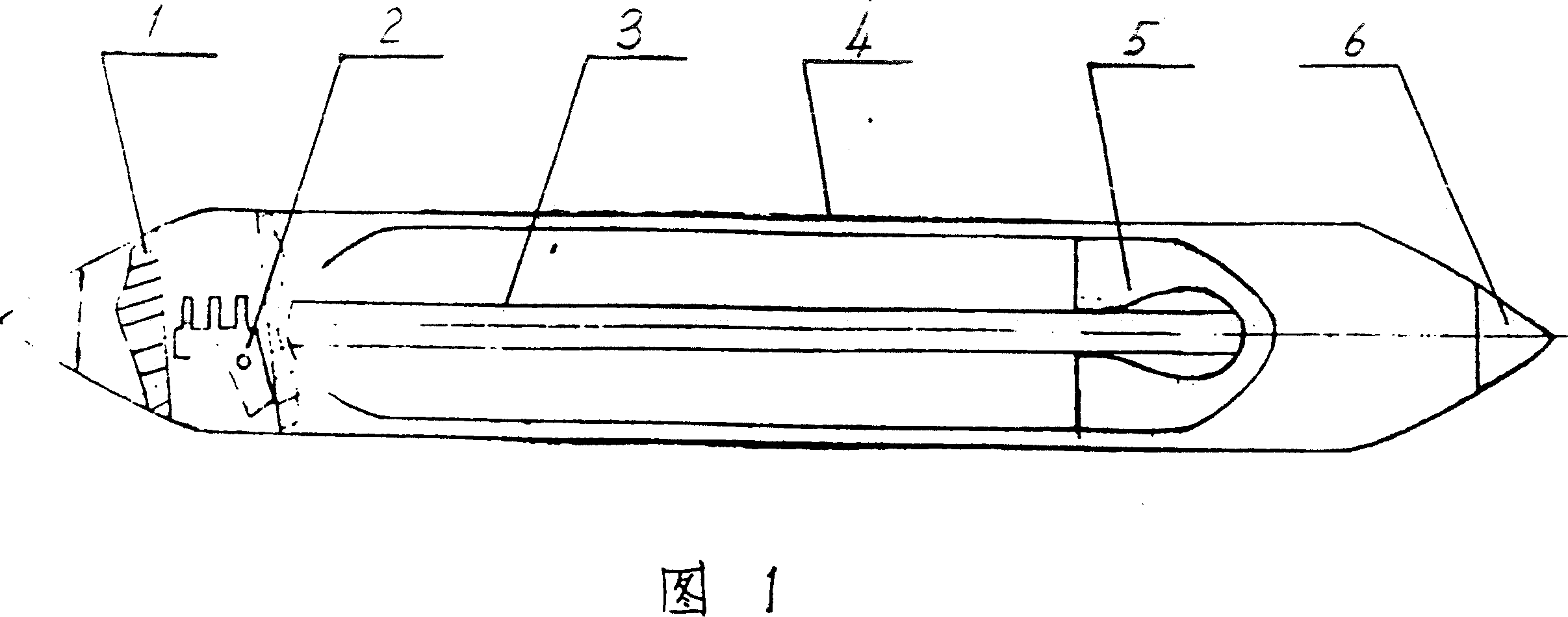

[0007] According to the accompanying drawings, the embodiment is further described in detail. The shuttle body 1 is made of reinforced bamboo. The outside of the shuttle body can be bonded firmly with steel paper to make the surface of the shuttle body clean and wear-resistant. The wooden shuttle body must be outside bonded steel paper, and the present invention can be used on the outer four sides of the shuttle body, and can also be bonded firmly without steel paper; any three sides outside the shuttle body can be bonded firmly with steel paper; any two sides outside the shuttle body It can be bonded firmly with steel paper composite. The implementation shows that the reinforced bamboo has smooth and wear-resistant properties.

[0008] The invention successfully utilizes bamboo to replace wood, and provides an effective way to solve the shortage of wood resources. The shuttle made of strengthened bamboo can be widely used in textile industries such as silk weaving, hemp weavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com