Coarctation hole series multi-operation part process technique and special equipment thereof

A technology of parts processing and special equipment, which is applied in the field of dense hole system multi-process parts processing technology and its special equipment, can solve the problems that the performance cannot meet the demand well, the equipment structure is complex, the machine tool structure is complicated, etc., and the production cycle is fast. , The structure of the equipment is simple, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

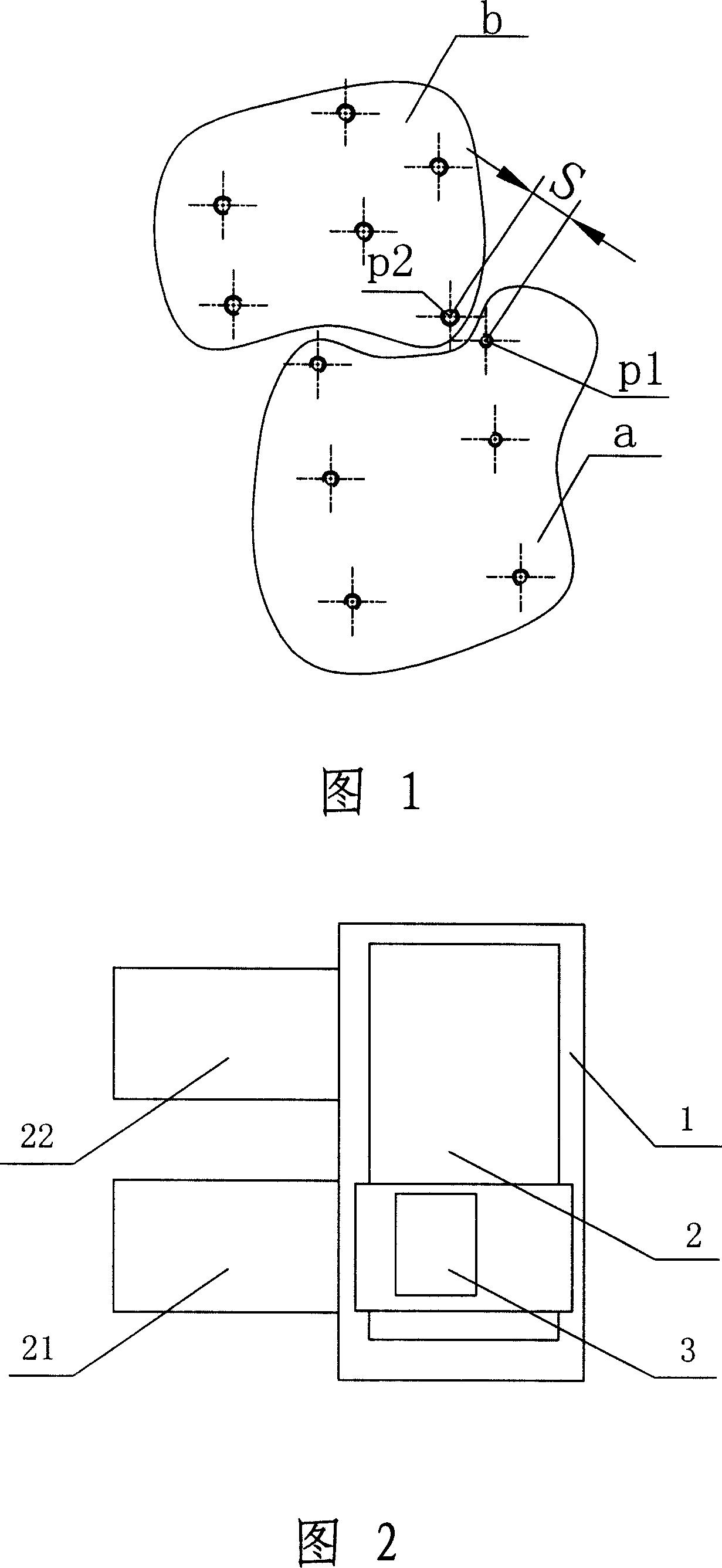

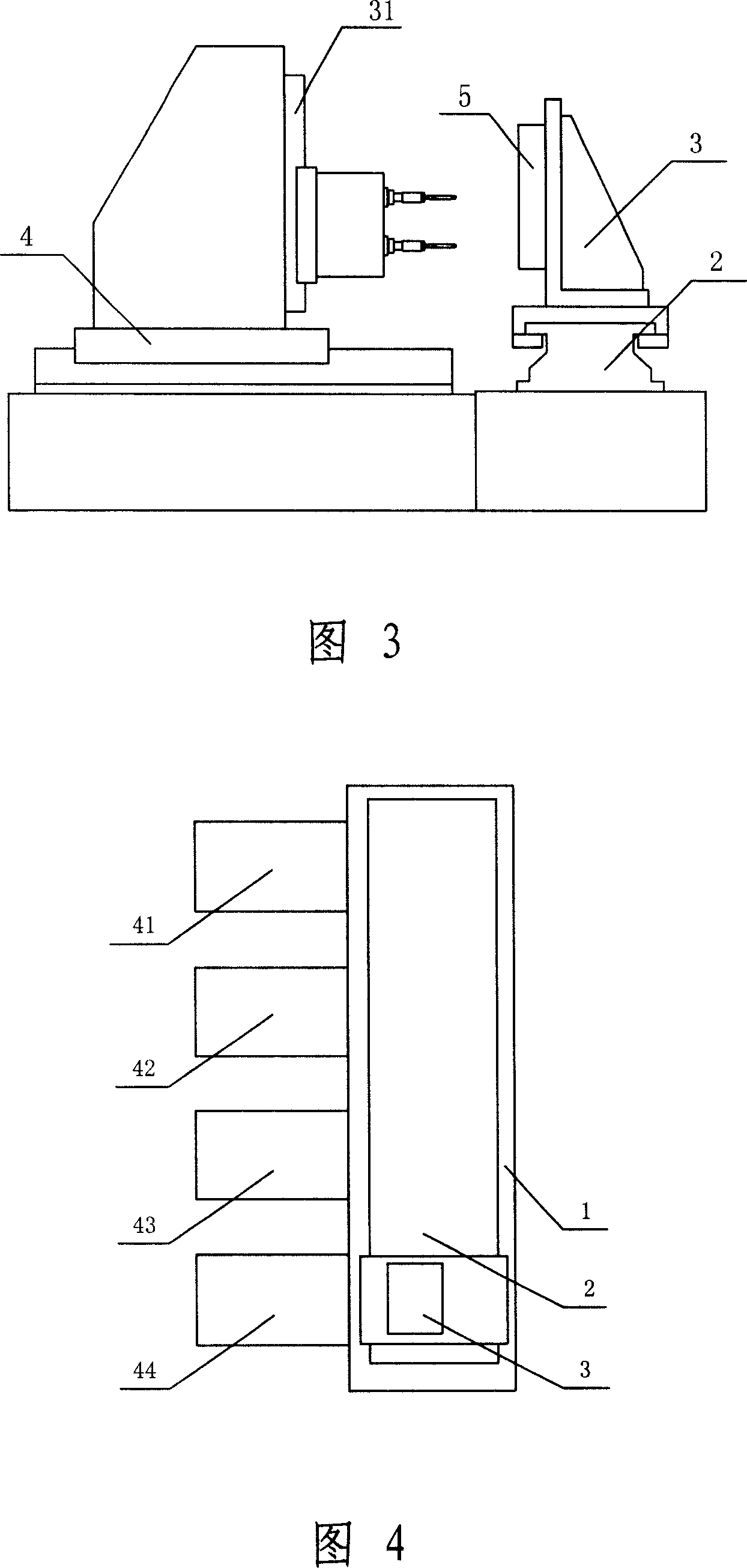

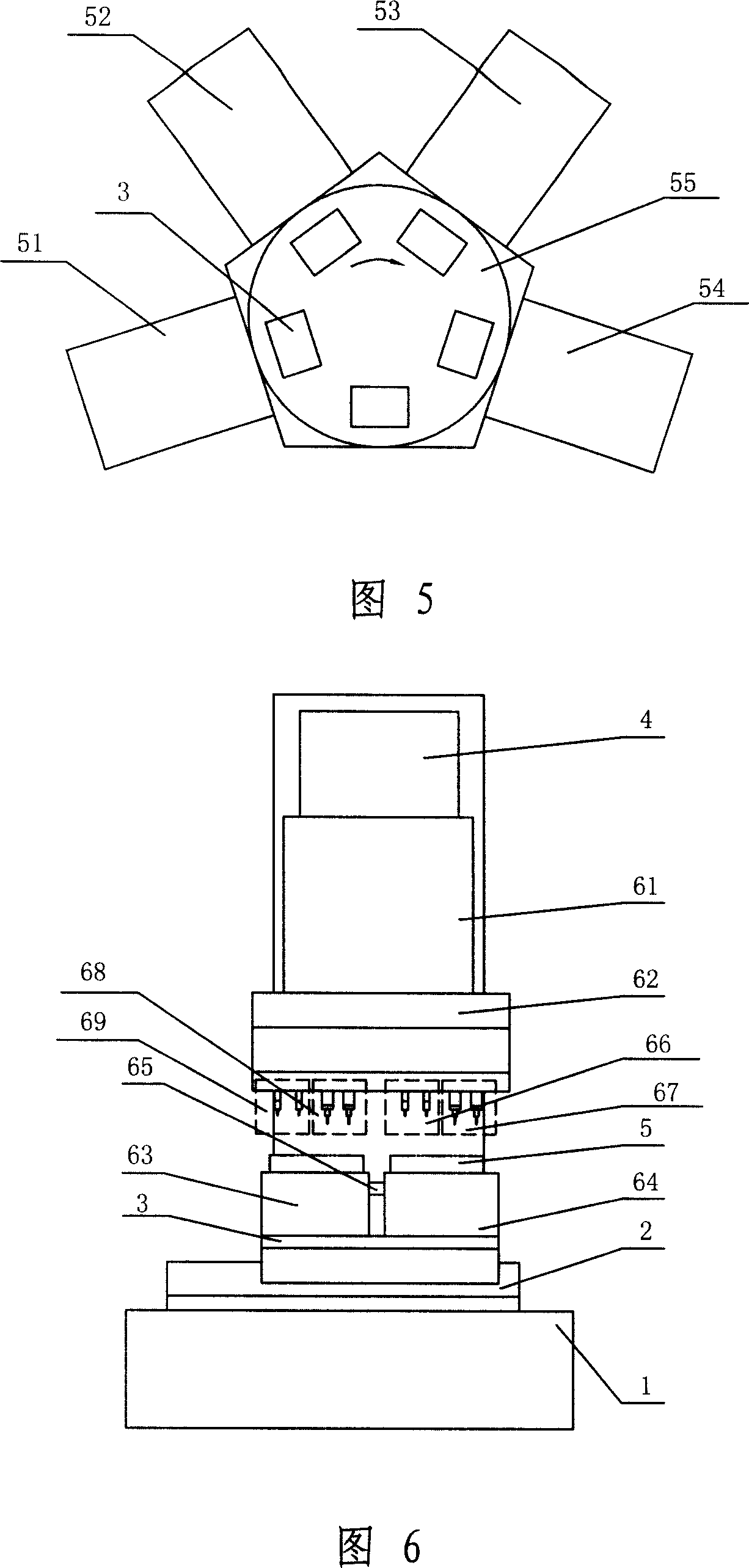

[0034] Dense hole system multi-process parts processing technology, its steps include loading and unloading, between loading and unloading, there are two processing units in sequence, each processing unit has two processing stations, these two stations are respectively For drilling and tapping, a single processing unit can independently complete the processing of a group of screw holes on the workpiece, and the corresponding processing stations of each processing unit are processed synchronously, and the workpiece sequentially passes through each processing unit described in each processing unit. The processing of the station, when the processing unit completes the processing of a group of holes in the workpiece, the workpiece is serially positioned from the current processing unit to the next processing unit, and the processing of the next group of holes is carried out, until the processing of the last group of holes is completed, and the work is completed. The workpiece is un...

example 2

[0036] Dense hole system multi-process parts processing technology, its steps include loading and unloading, between loading and unloading, there are three processing units arranged in sequence, each processing unit has two processing stations, the two working stations Each position is drilled and tapped separately, and a single processing unit can complete the processing of a group of corresponding holes on the workpiece independently, and the corresponding processing stations of each processing unit are processed synchronously, and the workpiece passes through each station in each processing unit in turn. When the processing unit completes the processing of a group of holes in the workpiece, the workpiece is serially positioned from the current processing unit to the next processing unit to process the next group of holes until the processing of the last group of holes is completed. The material is unloaded from the processing unit of the last group of holes, the workpieces o...

example 3

[0038] Dense hole system multi-process parts processing technology, its steps include loading and unloading, between loading and unloading, there are four processing units arranged in sequence, each processing unit has three processing stations, these three processing stations Drilling, chamfering and tapping (or similar drilling, reaming and reaming three-sequence processing), a single processing unit can independently complete the processing of a group of screw holes on the workpiece, and each processing unit Corresponding to the synchronous processing of the processing stations, the workpiece passes through the processing of each station in each processing unit in turn. When the processing unit completes the processing of a group of holes in the workpiece, the workpiece is serially positioned from the current processing unit to the next processing unit for the next group. Holes are processed sequentially until the processing of the last group of holes is completed. The finishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com