Wafer thinning method

A technology of wafers and polymer materials, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of stress fragments and warpage, expensive, pollution, etc., and achieve the effect of preventing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

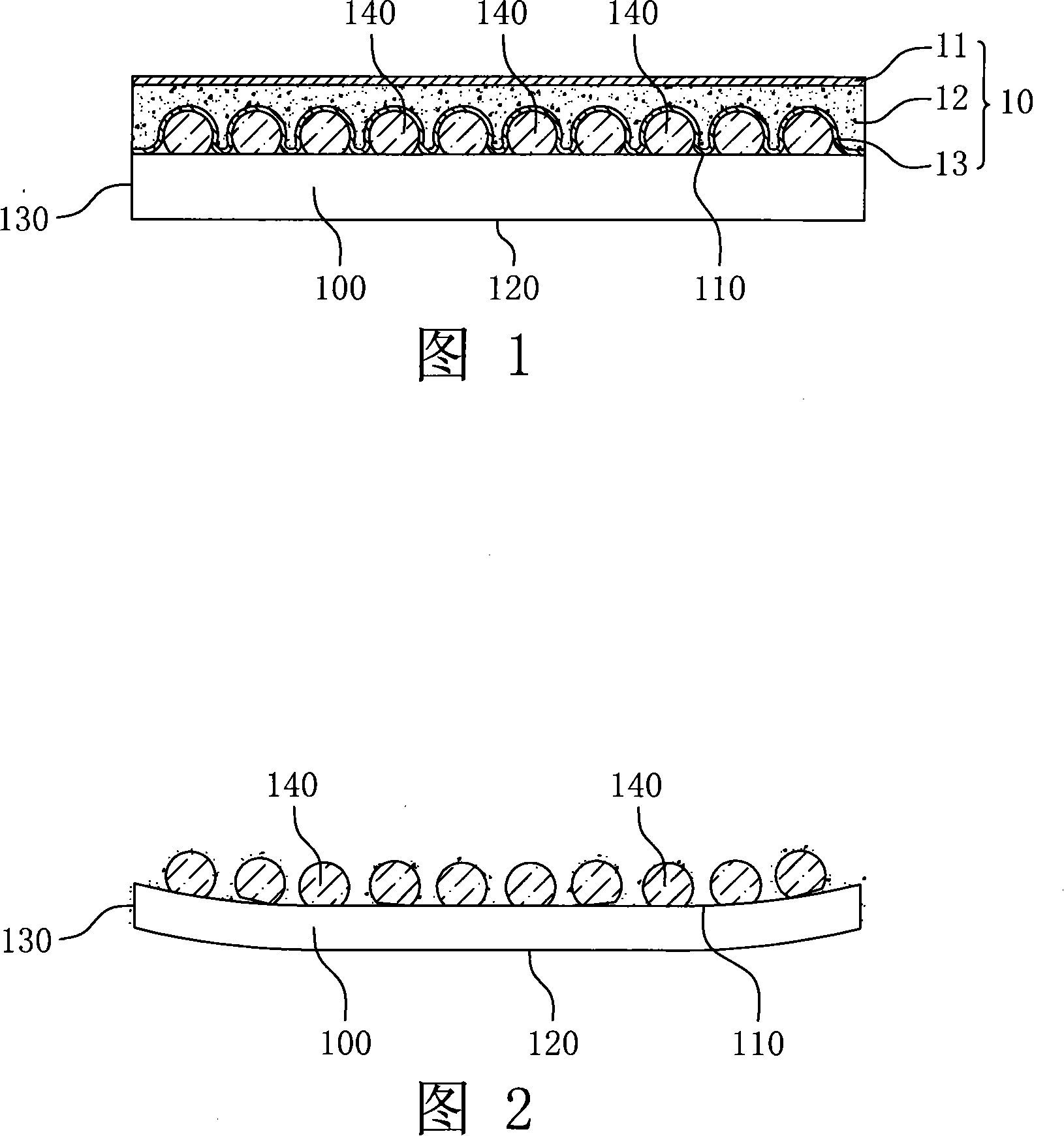

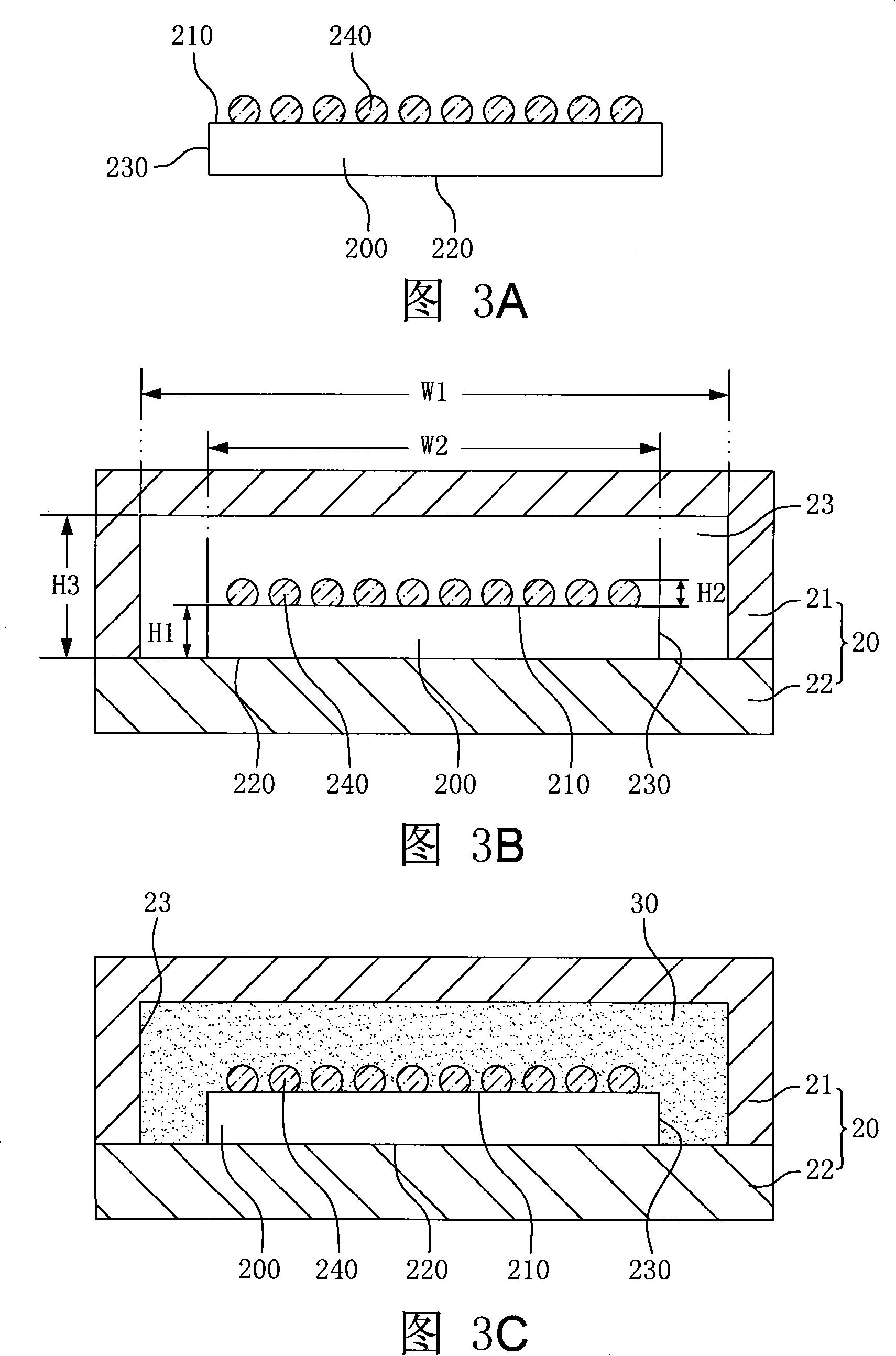

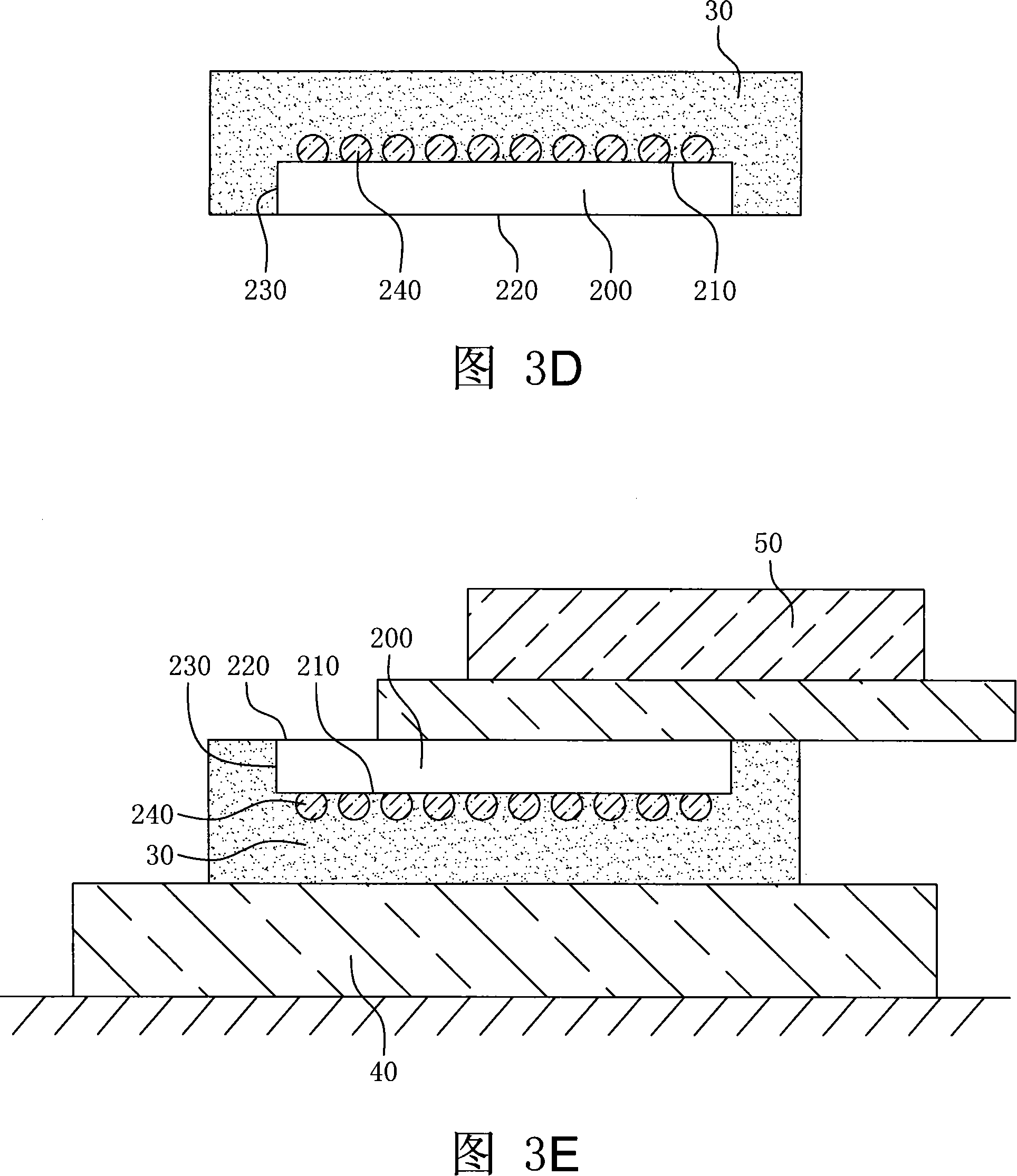

[0016] Please refer to FIG. 3A to FIG. 3E , a wafer thinning method is disclosed according to a first embodiment of the present invention. First, please refer to FIG. 3A , a wafer 200 is provided, and the wafer 200 has an active surface 210 , a rear surface 220 and at least one side surface 230 between the active surface 210 and the rear surface 220. In this embodiment, the active surface 210 of the wafer 200 is provided with several protruding elements 240, and these protruding elements 240 are selected From bumps, solder balls or passive components, in this embodiment, these protruding elements 240 are bumps. Then, referring to FIG. 3B, the wafer 200 is placed in a mold 20. The mold 20 includes an upper mold 21 and a lower mold 22. The upper mold 21 and the lower mold 22 form a mold cavity 23. The wafer 200 is placed On the lower mold 22 , the active surface 210 of the wafer 200 faces the upper mold 21 . In this embodiment, the width W1 of the mold cavity 23 is slightly lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com