Drainage treatment structure for working landfill slope underground water

A groundwater and landfill technology, which is applied in infrastructure engineering, construction, etc., can solve the problems of ineffective and poor adaptability of the anti-seepage layer, improve the drainage capacity, prevent recurrence, and ensure the anti-seepage effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

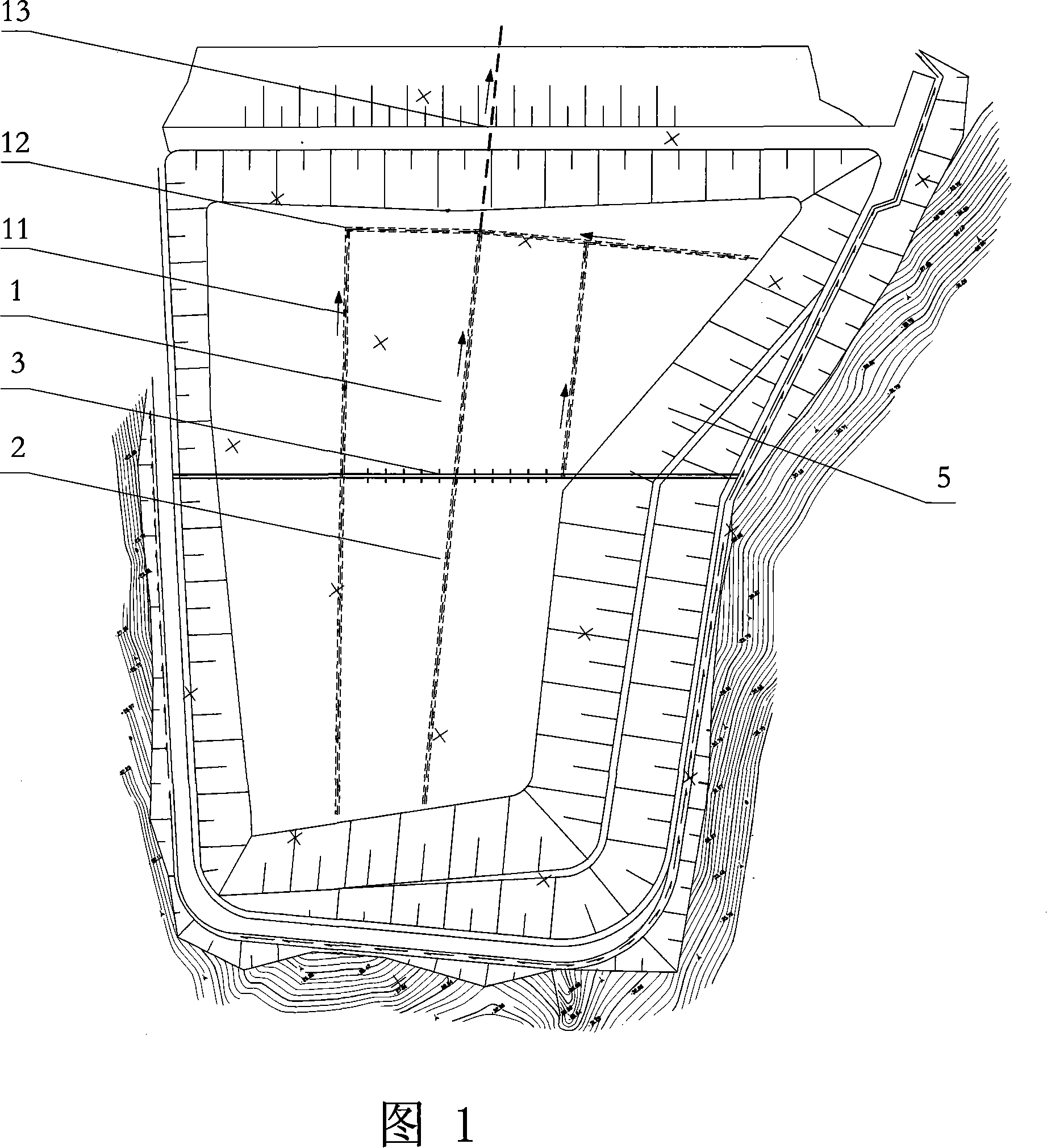

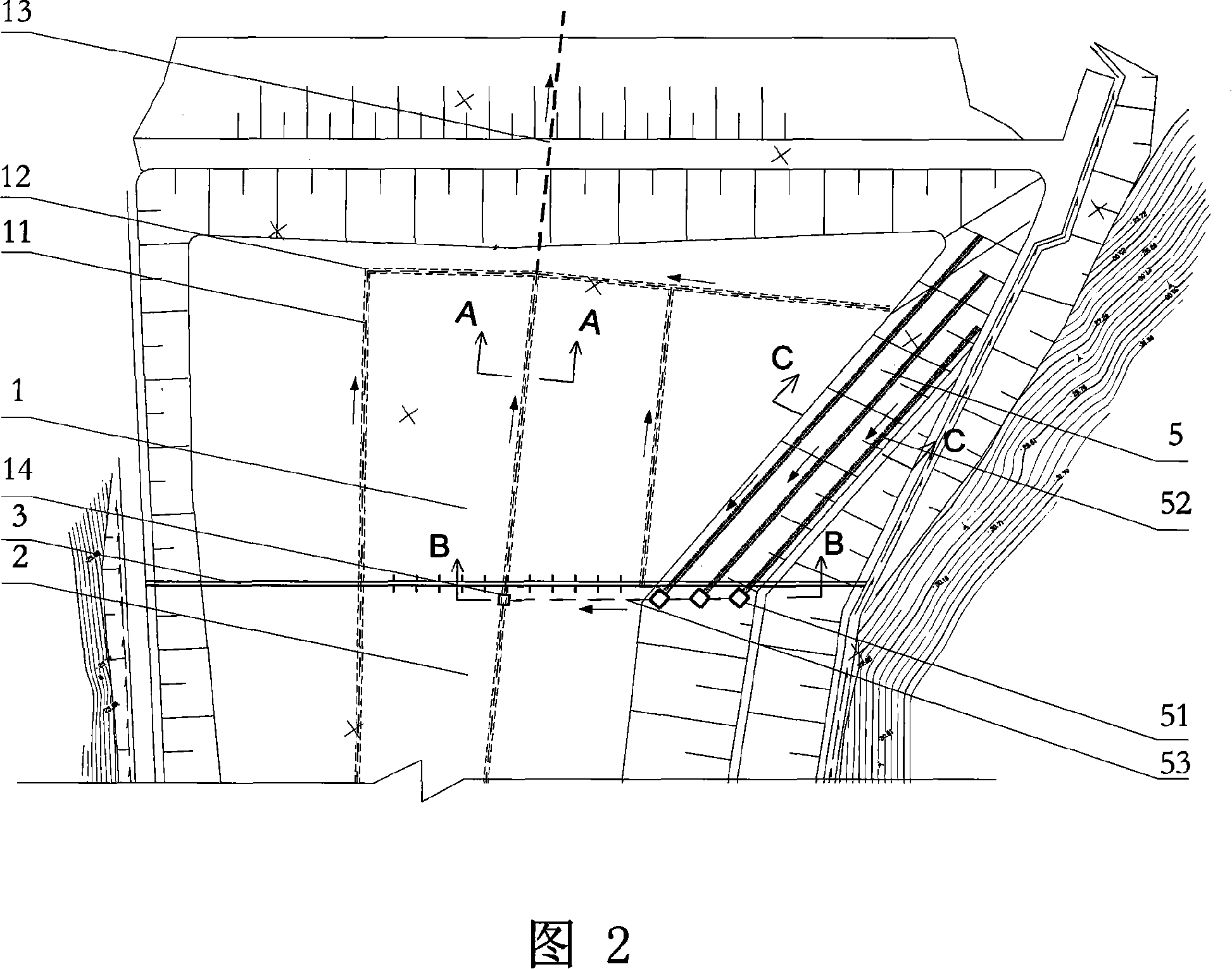

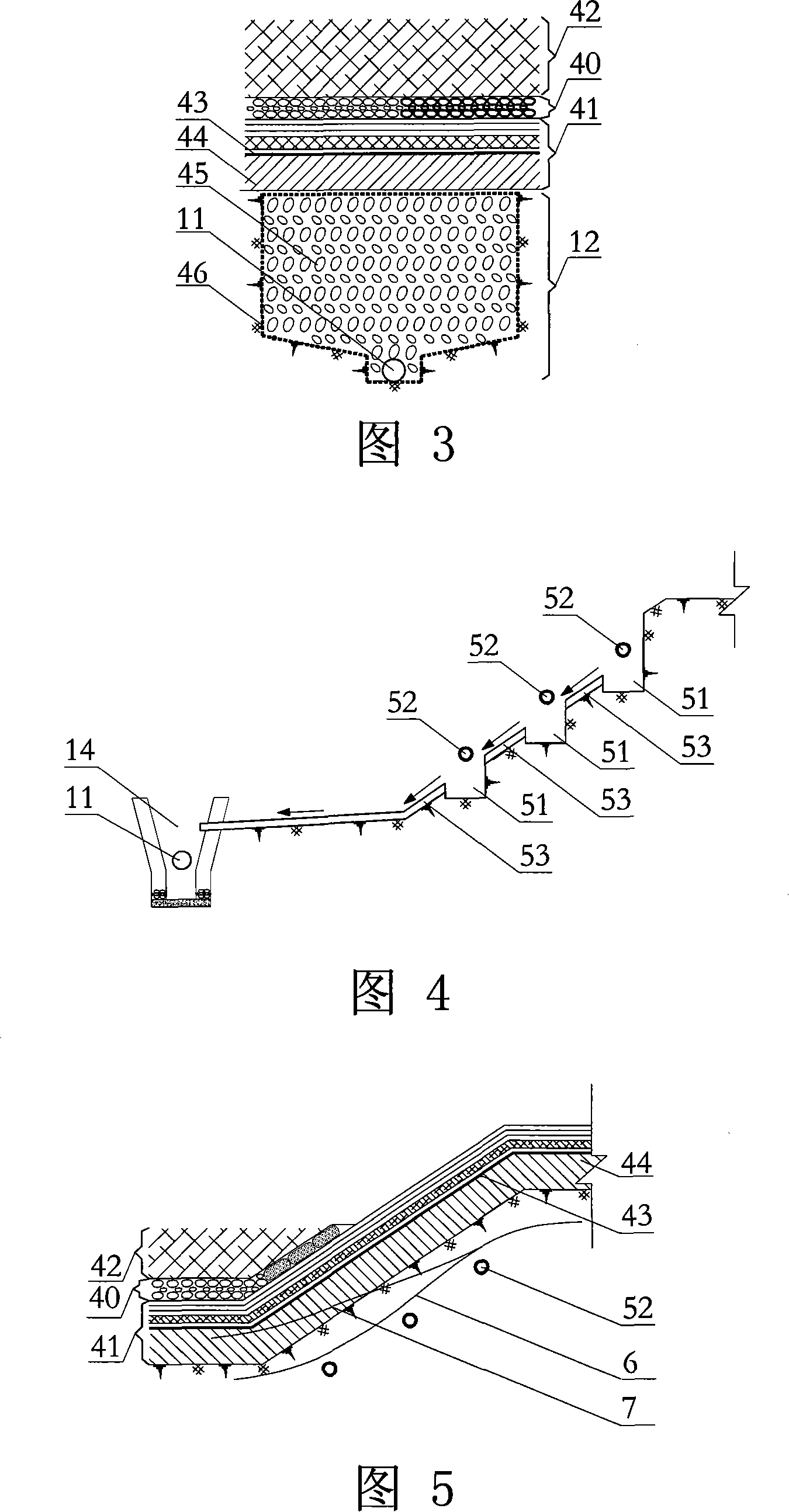

[0029] As shown in Fig. 2~Fig. 5, a kind of dredging treatment structure of groundwater of a kind of landfill slope that has been in operation of the present invention, in the landfill that has been in operation, the partition water retaining embankment 3 in the middle of the site area divides the landfill The landfill area is divided into the operating landfill area 1 in the north and the landfill area 2 without anti-seepage layer in the south. The bottom of the landfill area that has been in operation is laid with a leachate drainage layer 40 and an anti-seepage layer 41 sequentially from top to bottom. The permeable membrane 43 and the lower anti-seepage clay layer 44 are composed. Under the anti-seepage layer 41 at the bottom of the site, there is a groundwater drainage system at the bottom of the site. The groundwater drainage system at the bottom of the site includes a groundwater drainage pipe 11 at the bottom of the site, a blind ditch 12 for underground water drainage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com