Method for preparing dimethyl ether

A technology of dimethyl ether and methanol, which is applied in the field of methanol gas-phase dehydration to prepare dimethyl ether, can solve the problems of small catalyst processing capacity, short service life, high reaction temperature, etc., and achieve excellent reaction performance, high selectivity, and high activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

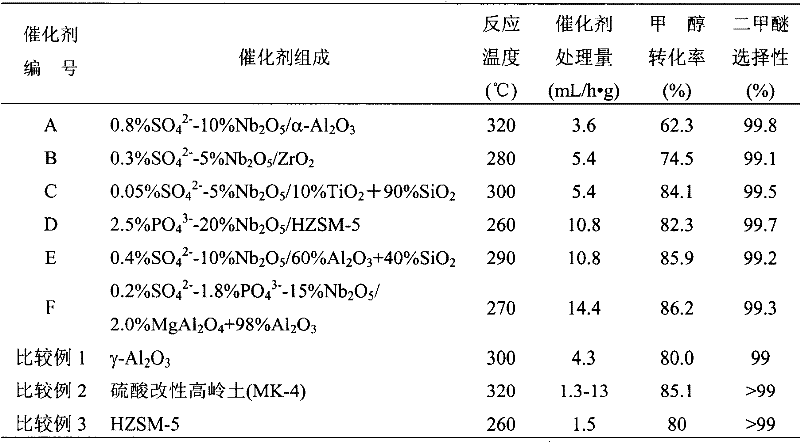

[0025] Fully mix 100 grams of aluminum hydroxide powder and 5 grams of asparagus powder, then add 50 milliliters of 4% (weight) dilute nitric acid, fully knead in a kneader to form a lump material, extrude into strips, and dry at room temperature For 24 hours, dry at 80°C for 2 hours, dry at 150°C for 2 hours, and bake at 1200°C for 4 hours to obtain strip-shaped α-Al 2 o 3 carrier. Dissolve commercially available niobic acid in oxalic acid to make a solution. This solution is impregnated in the prepared α-Al 2 o 3 On the carrier, dry at 120°C for 2 hours. The calculated amount of sulfuric acid solution was impregnated on the prepared catalyst precursor, dried at 120°C for 2 hours, and calcined in air at 400°C for 4 hours to obtain catalyst A. The catalyst composition is shown in Table 1.

Embodiment 2

[0027] The niobium amine complex was dissolved in water to make a solution with a concentration of 0.12 g / ml, and 0.6% polyacrylamide (calculated as tetra-n-butoxyzirconium) was added at the same time. Add the above solution into tetra-n-butoxyzirconium, stir vigorously at 40°C for 30 minutes, then add the calculated amount of concentrated sulfuric acid into the above solution, continue vigorously stirring for 10 minutes, and then stand still at 60°C until a gel is formed. It was left at room temperature for 48 hours, aged at 80°C for 16 hours, dried at 120°C for 4 hours, and calcined at 600°C for 4 hours in an ammonia atmosphere to obtain catalyst B. The composition of the catalyst is shown in Table 1.

Embodiment 3

[0029] Mix 40% (weight concentration) silica sol and titanium sol, and stir evenly. Then quickly add niobium ethoxide liquid to the above solution, stir vigorously at 40°C for 30 minutes, then add the calculated amount of concentrated sulfuric acid into the above solution, continue vigorously stirring for 10 minutes, and then stand still at 60°C until a gel is formed . It was left at room temperature for 48 hours, aged at 80°C for 16 hours, dried at 120°C for 4 hours, and calcined in a carbon dioxide atmosphere at 500°C for 4 hours to obtain catalyst C. The composition of the catalyst is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com