Chemical and mechanical grinding device

A grinding device and chemical mechanical technology, applied in grinding/polishing safety devices, grinding/polishing equipment, surface polishing machine tools, etc., can solve problems such as pit-shaped defects, wafer yield decline, etc., to improve yield, Ensure cleaning and reduce the effect of pit-like defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

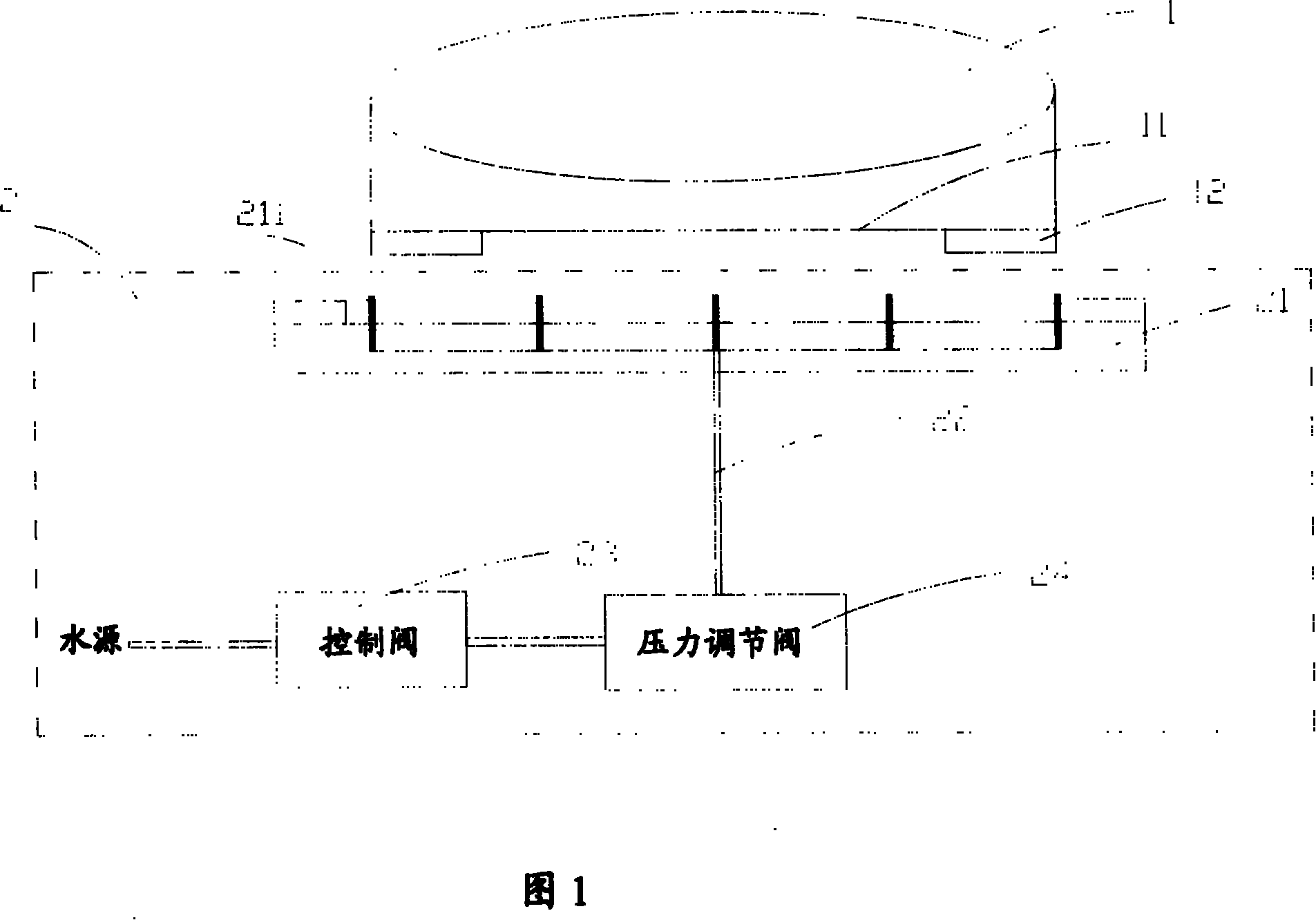

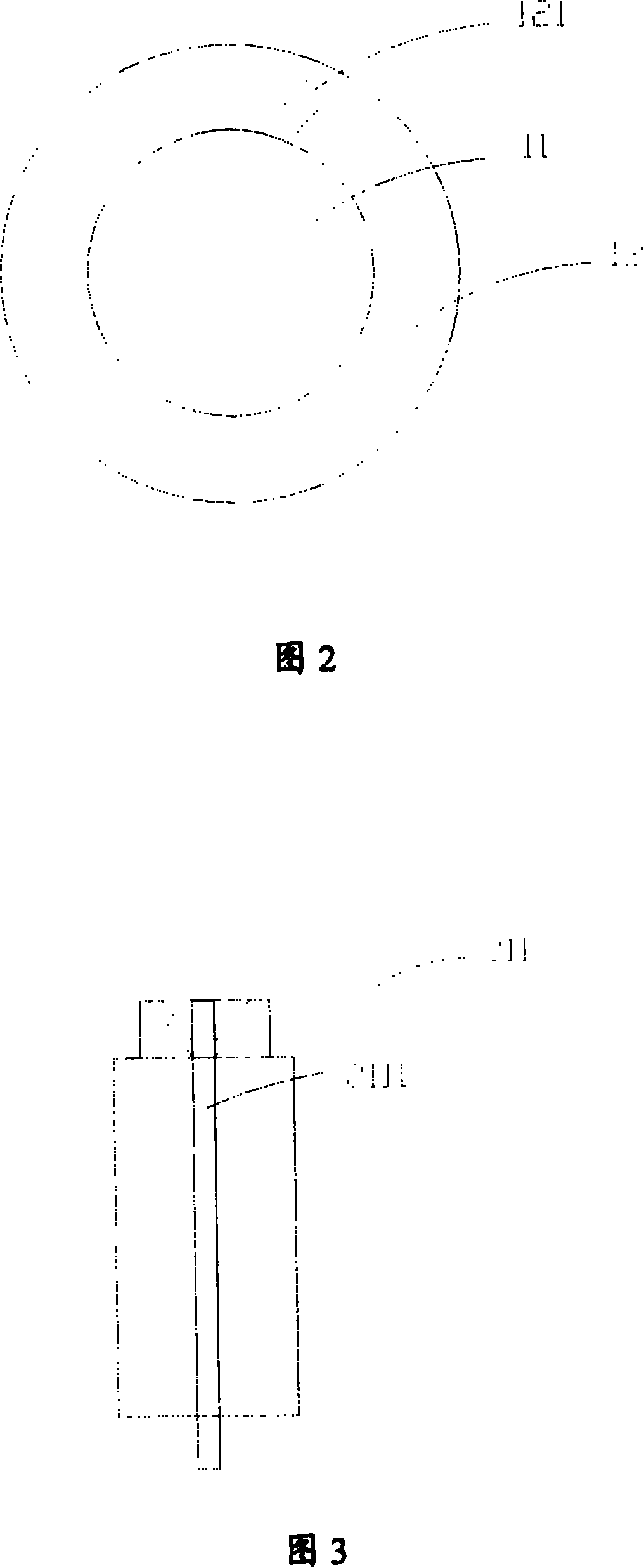

[0015] As shown in FIGS. 1 and 2 , the chemical mechanical polishing apparatus according to the present invention mainly includes a polishing head 1 and a polishing head cleaner 2 . The bottom surface of the polishing head 1 is constituted by the adsorption part 11 and the fixing ring 12 . The adsorption part 11 is used for adsorbing wafers (not shown) for grinding, and the fixing ring 12 is provided with a plurality of grooves 121 for discharging impurities during the grinding process.

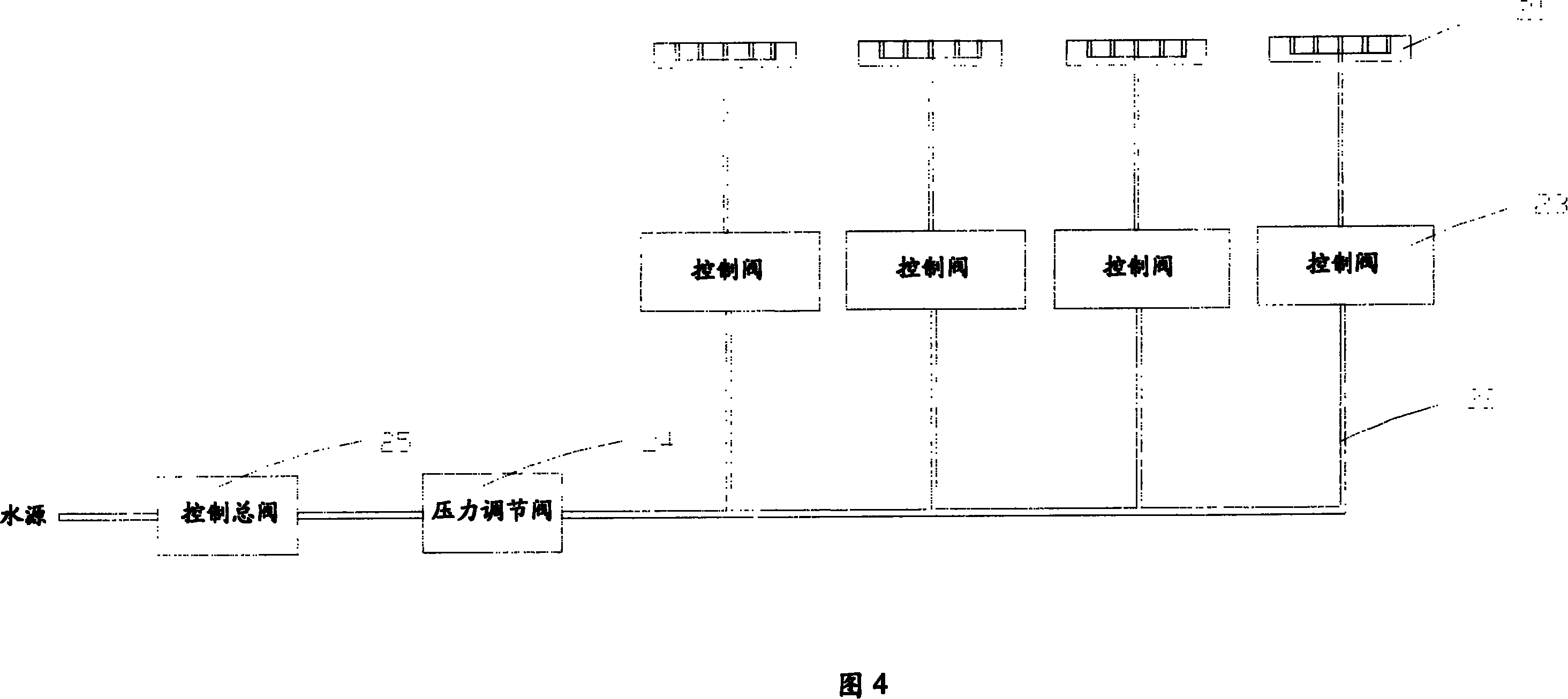

[0016] The polishing head cleaner 2 is used for cleaning the polishing liquid and the like remaining on the wafer. The grinding head cleaner 2 includes a grinding head flusher 21, a liquid passage 22 for introducing water into the flusher 21, a control valve 23 for controlling the conduction or closing of the liquid passage 22 through a control signal, and a pressure regulating valve 24 for controlling the water pressure. . It can be seen from FIG. 1 that the length of the grinding head flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com