Oil soluble comb polymers

A comb-shaped polymer and lubricating oil technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problems of shear stability and molecular weight decrease in parallel, achieve high viscosity index improvement, and simple preparation, easy The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-4

[0138] Into an apparatus equipped with a 4-neck flask and a KPG-saber stirrer was initially introduced 150 g of a mixture of low molecular weight monomers and macromers whose composition is shown in Table 3, along with 65 g of Shell Risella 907 oil and 35 g of KPE 100N oil. After heating to 120°C under nitrogen, 0.9 g of tert-butyl peroxybenzoate were added and the temperature was maintained. 3 hours and 6 hours after the first initiator addition, 0.3 g of tert-butyl peroxybenzoate were each successively supplied again, and the mixture was stirred at 120° C. overnight. On the second day the mixture was diluted with 125g of KPE 100 oil. 375 g of a 40% comb polymer solution in mineral oil are obtained.

Embodiment 8-11

[0140] Into an apparatus equipped with a 4-neck flask and a KPG-saber stirrer was initially introduced 150 g of a mixture of low molecular weight monomers and macromers whose composition is shown in Table 3, along with 65 g of Shell Risella 907 oil and 35 g of KPE 100N oil. After heating to 90° C. under nitrogen, 0.3 g of tert-butyl per-2-ethylhexanoate are added and the temperature is maintained. 3 hours and 6 hours after the first initiator addition, 0.3 g of tert-butyl per-2-ethylhexanoate were each successively supplied again, and the mixture was stirred at 90° C. overnight. The next day the mixture was diluted with 125g of KPE 100 oil. 375 g of a 40% comb polymer solution in mineral oil are obtained.

Embodiment 12 and 13

[0142] Into an apparatus equipped with a 4-necked flask and a KPG-saber stirrer were initially introduced 150 g of a mixture of low molecular weight monomers and macromers whose composition is shown in Table 3, and 100 g of toluene. After heating to 90° C. under nitrogen, 0.3 g of tert-butyl per-2-ethylhexanoate are added and the temperature is maintained. 2 hours, 4 hours, 6 hours and 8 hours after the first initiator addition, 0.3 g of tert-butyl per-2-ethylhexanoate were each successively supplied again, and the mixture was stirred at 90° C. overnight. The next day the mixture was diluted with 225 g of KPE 100N oil and the toluene was removed by degassing on a vacuum rotary evaporator. 375 g of a 40% comb polymer solution in mineral oil are obtained.

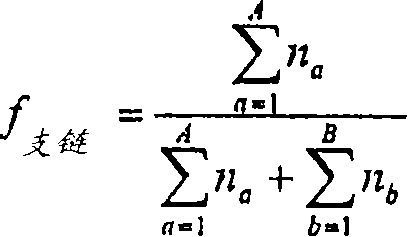

[0143] Considering the net composition of macromonomers and low molecular weight monomers forming 150 g and the functionality of the macromonomers f MM , to determine the net composition in terms of the mass fraction of eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com