Preparation method of surface reinforced Raman diffuse transmission substrate

A surface-enhanced Raman and substrate technology, applied in the fields of materials, biology, and optics, can solve the problems of limited nanoparticle size and inability to directly apply SERS

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

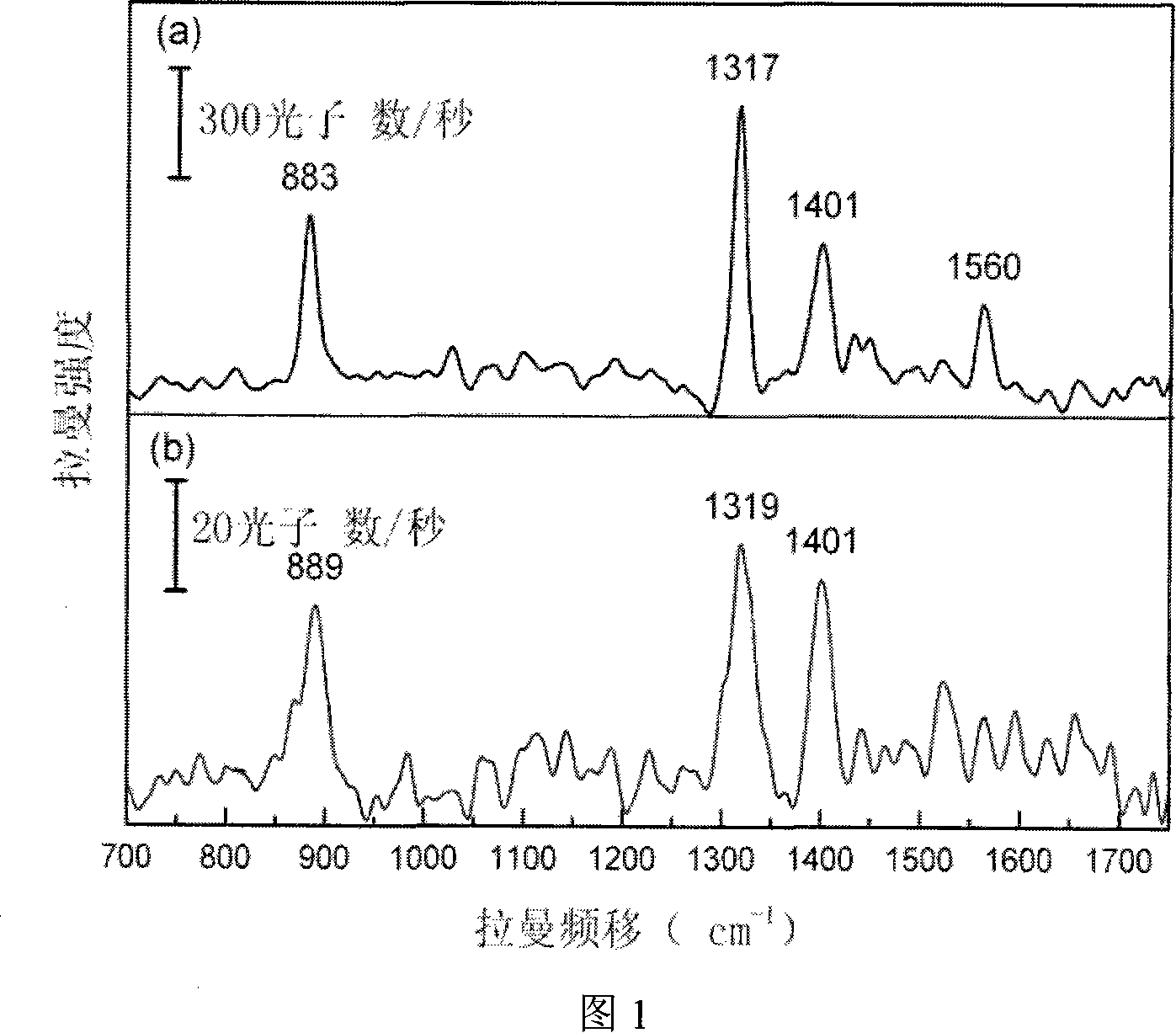

[0018] What the present embodiment selects is silver-doped silica glass (the content of silver ion is 0.1mol%), and the peak power of femtosecond laser is 2 * 10 11 W, focusing on the glass surface through a microscope objective lens, and scanning with a three-dimensional mobile platform to obtain a sensing area with a width of 50 microns and a length of 300 microns. The prepared glass is placed in silver nitrate solution, soaked for a certain period of time, grows into a noble metal film layer with nano-roughness, and forms a surface-enhanced Raman scattering substrate. Glycine with a concentration of 1 mol / L was dropped on the sensing area, and its Raman spectrum was measured to be 2500 times that of that without substrate, which realized the enhancement of the Raman spectrum of the sample, and the results are shown in Figure 1. In the figure (a) surface-enhanced Raman spectrum of glycine molecule, the measurement concentration is 1mol / L, and the integration time is 20 secon...

Embodiment 2

[0020] What this embodiment selects is silver-doped silica glass (the content of silver ion is 0.1mol%), utilizes pulse width to be 400 femtoseconds, repetition frequency 100 Hz, central wavelength 780 nanometers, power is 8 milliwatts (peak power is 2× 10 10 The laser light of W) is focused on the glass surface through a microscope objective lens, and scanned with a three-dimensional mobile platform to obtain a sensing area with a width of 50 microns and a length of 300 microns. The prepared glass is placed in silver nitrate solution, soaked for a certain period of time, grows into a noble metal film layer with nano-roughness, and forms a surface-enhanced Raman scattering substrate.

Embodiment 3

[0022] What this embodiment selects is silver-doped silica glass (the content of silver ion is 0.1mol%), utilizes pulse width to be 10 femtoseconds, repetition frequency 10 Hz, central wavelength 830 nanometers, power is 20 milliwatts (peak power is 2× 10 12 The laser light of W) is focused on the glass surface through a microscope objective lens, and scanned with a three-dimensional mobile platform to obtain a sensing area with a width of 50 microns and a length of 300 microns. The prepared glass is placed in gold chlorate solution, soaked for a certain period of time, and grows into a noble metal film layer with nano-roughness, forming a surface-enhanced Raman scattering substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com