Polymer modified expanded perlite and method for making same

A technology of expanded perlite and polymer, which is applied in the field of polymer-modified expanded perlite material and its preparation, which can solve the problems of crushing, increase of mortar bulk density, and decline of product quality, and achieve simple preparation process and solve the problem of product quality degradation , Ease of implementation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

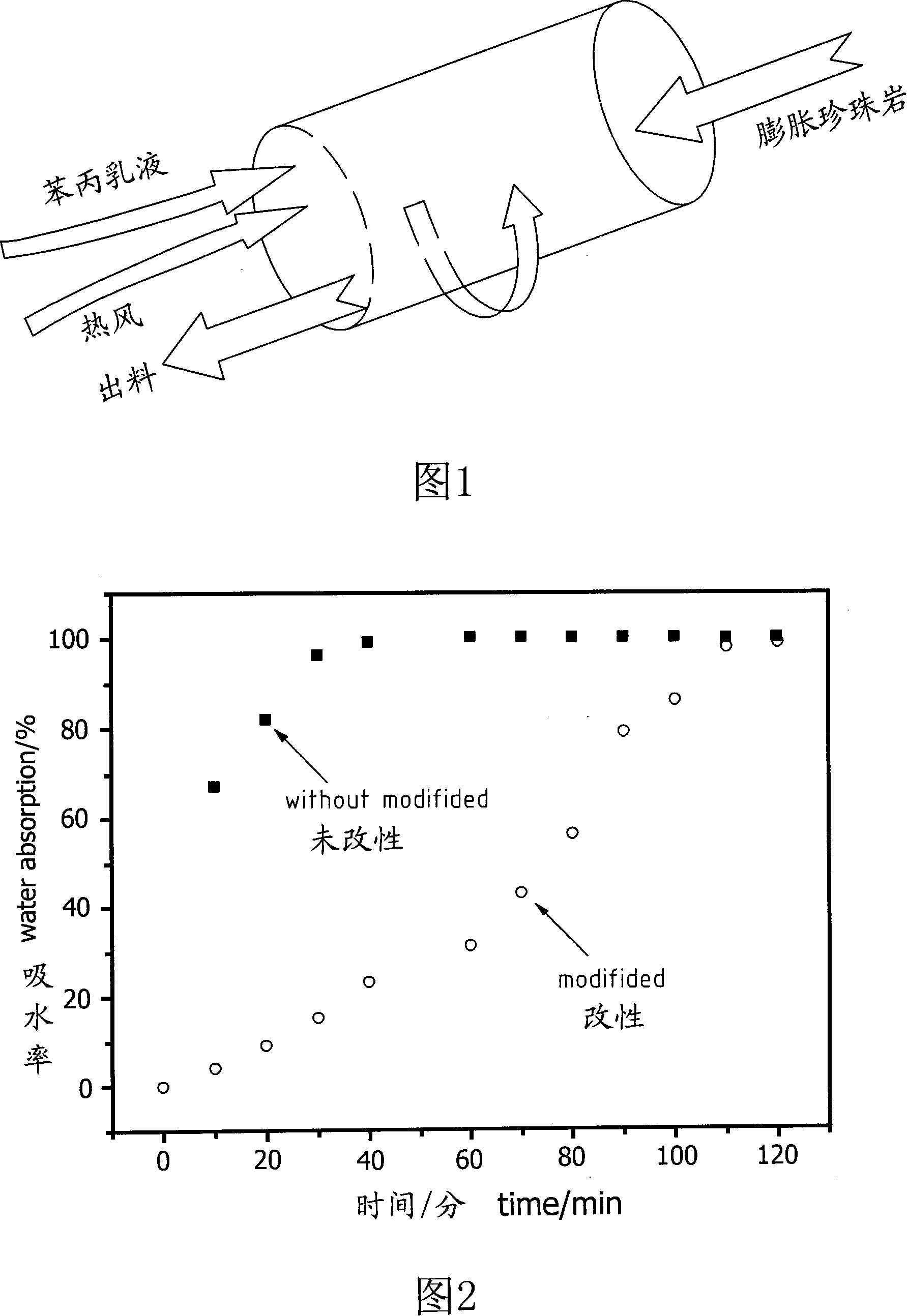

[0020] Referring to Fig. 1, the expanded perlite with a particle size range of 2 mm is sent into the rotating drum, and the styrene-acrylic emulsion is micro-misted with hot air at 80° C. In the drum; the expanded perlite is in full contact with the hot mist of the styrene-acrylic emulsion in the drum, thereby forming a polymer film with a certain strength on the surface, and it is discharged from the discharge port, that is, the expanded perlite particles modified by the styrene-acrylic emulsion are obtained. .

[0021] Referring to Figure 2, ordinary expanded perlite reaches saturated water absorption in 30 minutes, while expanded perlite particles modified by styrene-acrylic emulsion reach saturated water absorption in 110 minutes, and the water absorption has been significantly reduced; at the same time, the strength has also been significantly improved , The volume loss rate dropped from the original 70% to 23% under the cylinder compressive strength of 1MPa, the problem ...

Embodiment 2

[0023] The expanded perlite with a particle size range of 8mm is sent into the rotating drum, and at the same time, the polyurethane micro-mist is sent into the rotating drum with hot air at 60 ° C. The quality of polyurethane: the quality of expanded perlite = 1: 3, and the expanded perlite is in the rotating drum. Fully contact with the hot mist formed by polyurethane, so that a polyurethane film with a certain strength is formed on the surface, and the material is discharged from the discharge port, that is, polyurethane modified expanded perlite particles are obtained.

[0024] Ordinary expanded perlite reaches saturated water absorption in 30 minutes, and the expanded perlite particles are modified by polyurethane, while the modified expanded perlite reaches saturated water absorption in 250 minutes, and the water absorption has been significantly reduced; at the same time, the strength has also increased. It has been significantly improved, and the volume loss rate has dr...

Embodiment 3

[0026] The expanded perlite with a particle size range of 4mm is sent into the rotating drum, and at the same time, the polyacrylic acid emulsion, the quality of the polyacrylic acid emulsion: the quality of expanded perlite = 1: 3, is sent into the rotating drum in the form of a spray by hot air at 90°C; The perlite is in full contact with the hot mist formed by the polyacrylic acid emulsion in the drum, so that a polyacrylic acid emulsion film with a certain strength is formed on the surface, and it is discharged from the discharge port, that is, the polyacrylic acid emulsion modified expanded perlite particles are obtained. .

[0027] Ordinary expanded perlite reaches saturated water absorption in 30 minutes, expanded perlite particles modified by polyurethane, and modified expanded perlite reaches saturated water absorption in 360 minutes, and the water absorption has been significantly reduced; at the same time, the strength has also increased It has been significantly im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com