Self-spreading pre-heating powder aqueous medium bidirectional blasting and concreting device

A self-propagating, water-medium technology, applied in the field of preparing high-density hard-to-consolidate metal composite materials and their functional gradient materials, can solve the problems of long heating time, mold softening, short pulse duration, etc., to reduce strong reflection, good Flatness, the effect of improving the consolidation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

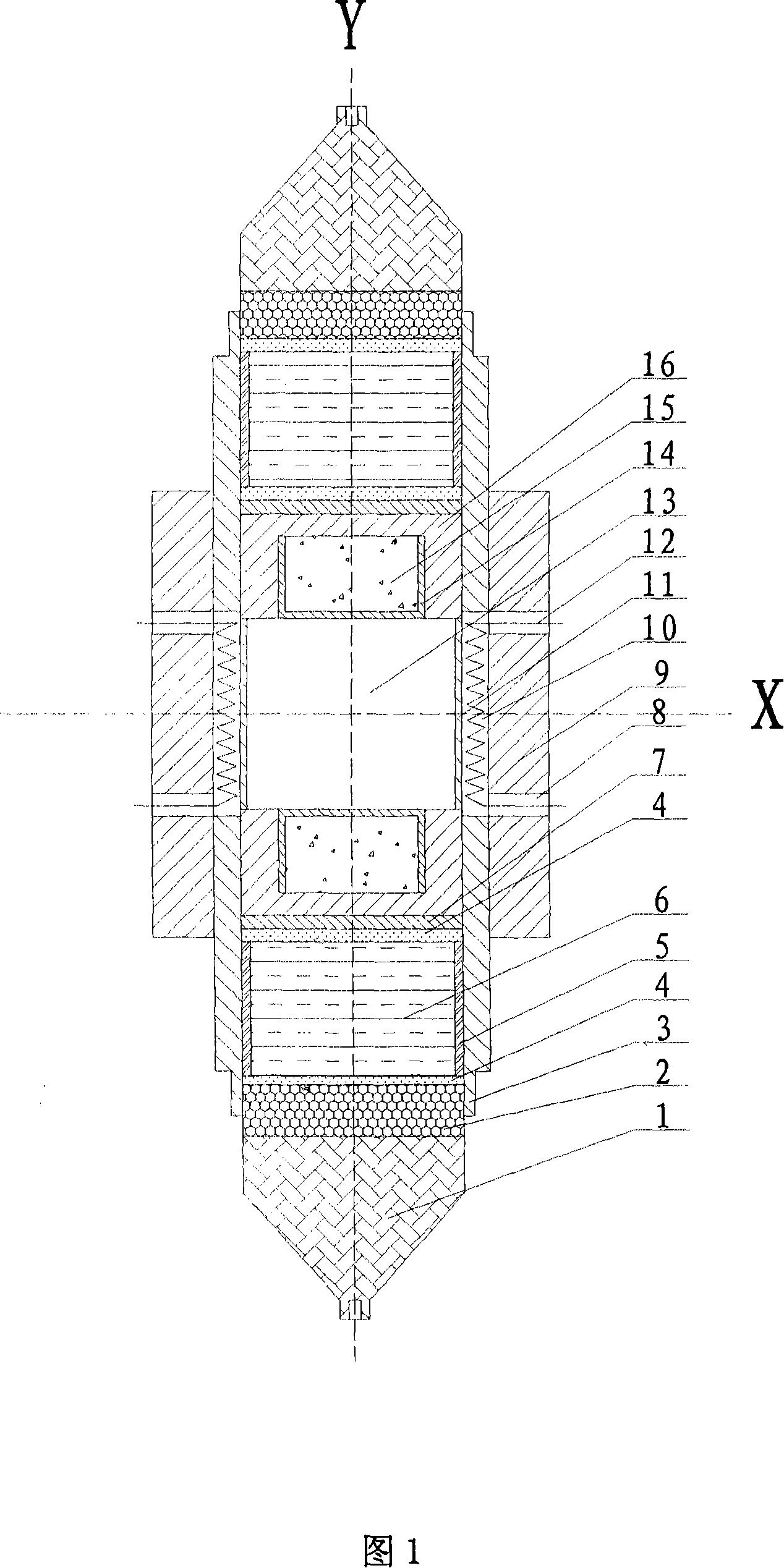

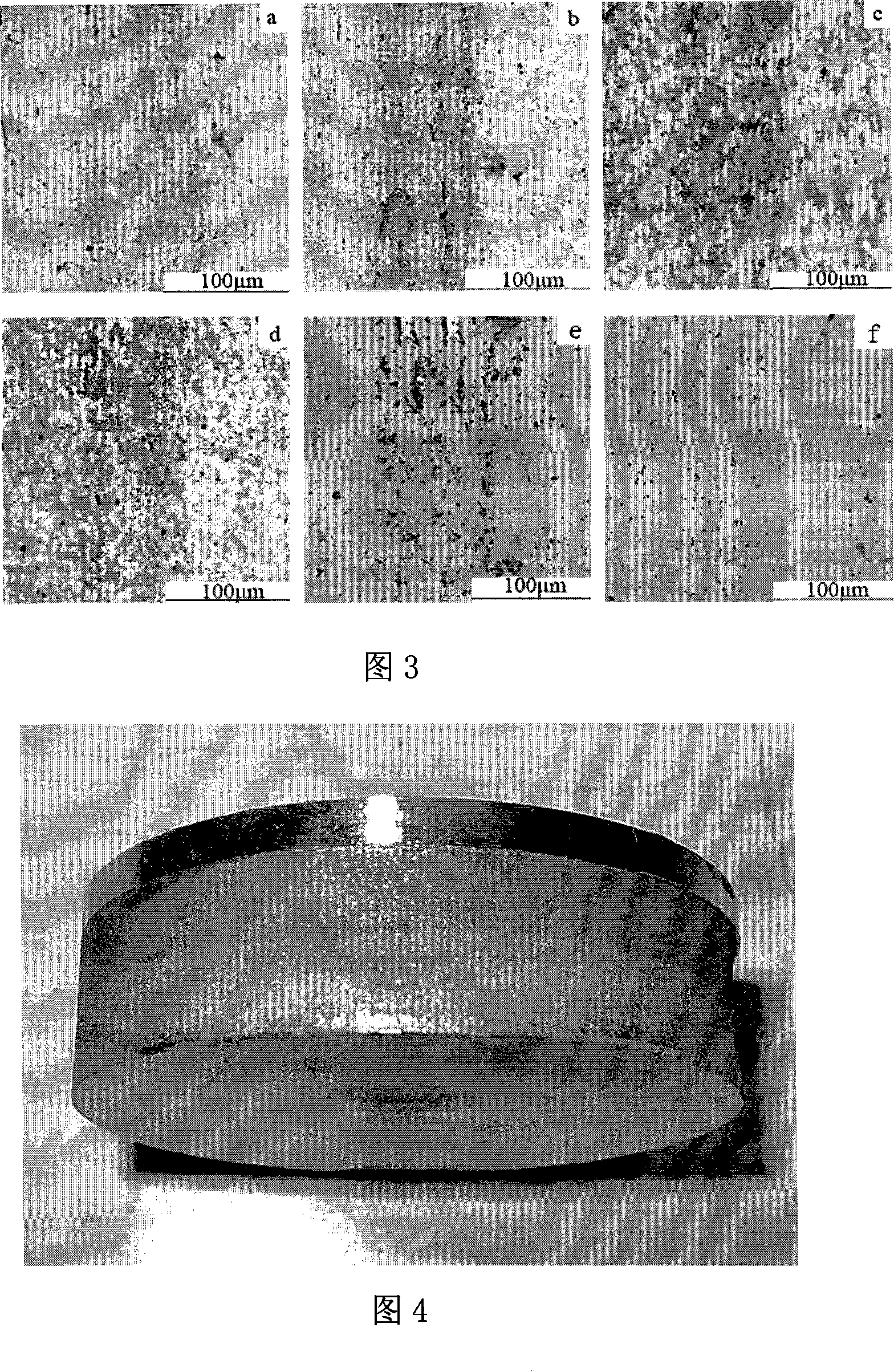

[0032] Example 1: Explosive consolidation of Mo / Cu FGM with a sample diameter of Φ30mm

[0033] Using the explosive consolidation device in Figure 1, the purity of Mo powder used in the test is greater than 99.9%, and the average particle size is 3 μm. The purity of Cu powder is greater than 99%, and the average particle size is 74 μm. The sample is divided into seven layers, the first layer is a pure Mo layer with a thickness of 3mm, the seventh layer is a pure Cu layer with a thickness of 2mm, and the transition layer is divided into five layers, each layer is 1mm, and the total thickness is 5mm. In this test, the component distribution index p=2 was used. Each layer is proportioned according to the design percentage, wet mixed for 8 hours, dried and ball milled for 2 hours, and then filled layer by layer into a Φ30mm steel pressure mold for compression molding. The diameter of the powder base is Φ30mm, and the calculated relative density is 58.82%.

[0034] Using (TiO 2...

example 2

[0036] Example 2: Explosive consolidation of W(Mo) / Cu FGM with a sample diameter of Φ30mm

[0037] Using the explosive consolidation device in Figure 1, the average particle size of W powder is 1 μm, 3 μm, 12 μm, and 20 μm, and the mixed powder is mixed according to the design grade. The particle size of molybdenum powder is 33 μm, the purity of Cu powder is greater than 99%, and the average particle size is 74 μm. The sample is divided into seven layers, the first layer is a W-Mo layer with a thickness of 3mm, the seventh layer is a pure Cu layer with a thickness of 2mm, and the gradient layer is divided into five layers, each layer is 1mm, and the total thickness is 5mm. In this test, the ingredient distribution index p=1.5 was used. Each layer is batched according to the design percentage, wet mixed for 8 hours, dried and ball milled for 2 hours, and then filled layer by layer into a Φ30mm steel pressing mold for compression molding. The diameter of the powder blank is Φ30m...

example 3

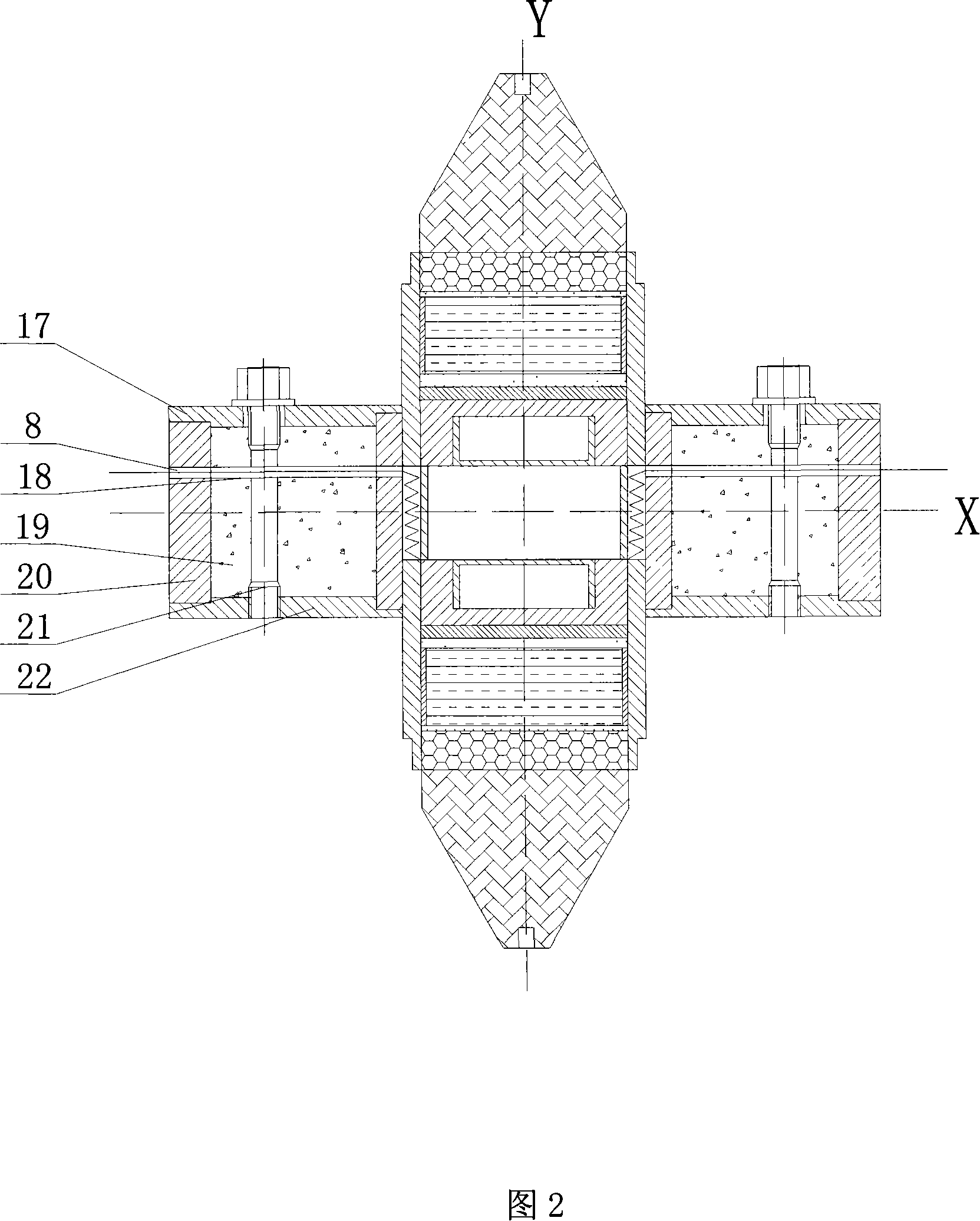

[0039] Example 3: Explosive consolidation of W(Mo) / Cu FGM with a sample diameter of Φ50mm

[0040] The explosive consolidation device shown in Figure 2 is used with the same self-propagating mixing system. Tungsten powders with different particle sizes were used in the test, namely 1 μm, 3 μm, 10 μm, 12 μm, and 20 μm. For coarser tungsten powder, the method of grading is used for batching. The alloy layer is mixed with 40% molybdenum by volume, 30% tantalum by volume, 1% lanthanum oxide by mass, or simultaneously doped with molybdenum, tantalum and lanthanum oxide. The particle size of the molybdenum powder is 3 μm, the particle size of the tantalum powder is 30 μm, the lanthanum oxide is analytically pure lanthanum oxide, and the copper powder is electrolytic copper powder with a particle size of ≤75 μm.

[0041] The gradient layer adopts different distribution exponent p values, which are 1.0, 1.2, 1.5, and 2, respectively. The explosively consolidated sample consists of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com