Hollow round ingot casting hot-top casting device and method for casting hollow tube thereof

A technology of hot top casting and hollow circle, which is applied in the field of casting thin-walled hollow tubes, can solve problems such as instability, oxide film damage, gate cracks, etc., so as to reduce process losses, improve economic benefits, and improve metal plasticity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

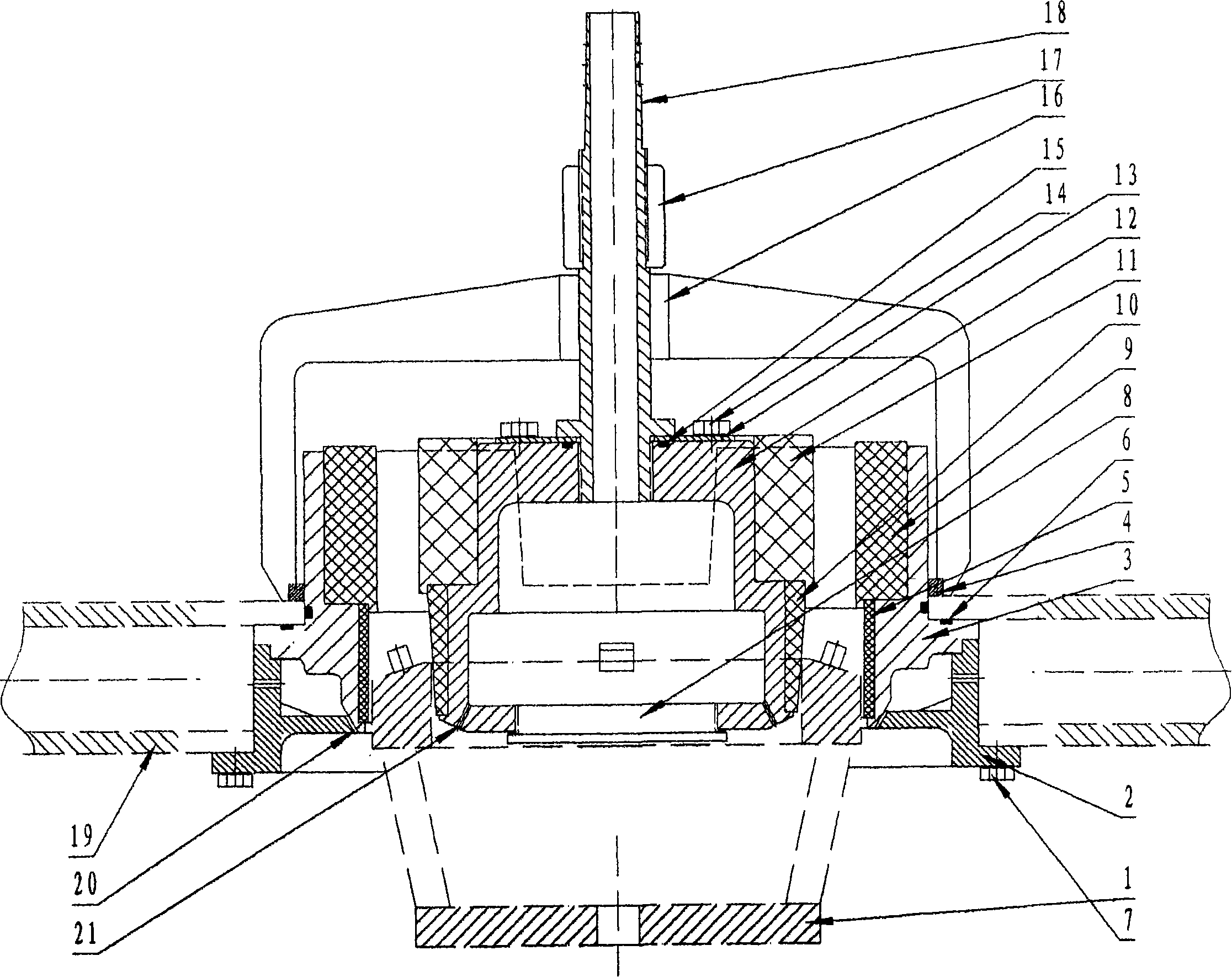

[0011] With reference to the accompanying drawings, the hollow round ingot hot top casting device consists of an outer jacket 2 and a core support 16 mounted on the limit gland 4, a core 12 and upper and lower sleeve core insulation caps 11, core Graphite cover 10, condensation tank 3, condensation tank insulation cap 9 and condensation tank graphite bushing 5, core water inlet pipe 18 and core outlet hole 21, water inlet tank 19 and condensation tank outlet hole 20, core plugging wire 8 and assembly It consists of dummy 1 etc. on the semi-continuous ingot casting machine. The core water inlet pipe 18 and the core junction have a pressing plate 13 and a core sealing ring 15, and the pressing plate 13 and the core sealing ring 15 are connected and fixed with bolts 14. A sealing ring 6 is arranged between the condensation tank 3 and the water tank 19 .

[0012] The crystallization zone formed between the core graphite sleeve 10 and the condensation groove graphite liner 5 is 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com