Radiation device assembly and fastener using the same

A heat dissipation device and buckle technology, which is applied in the cooling of instruments, parts of instruments, cooling/ventilation/heating transformation, etc., can solve the problems of difficult disassembly, falling off, easy deformation under force, etc., and achieve convenient and stable assembly , easy to operate, not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

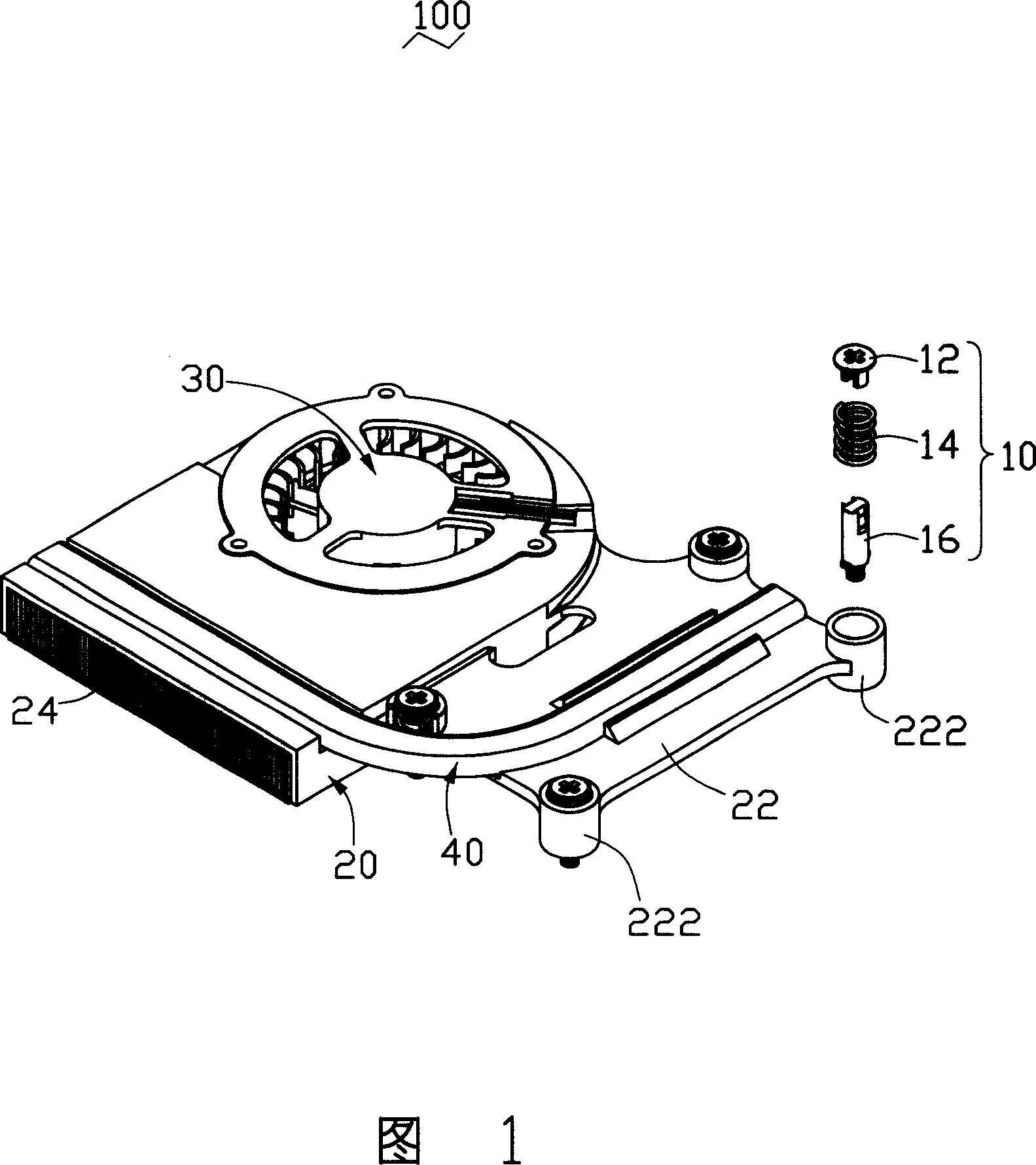

[0019] FIG. 1 is an exploded perspective view of the first embodiment of the heat dissipation device assembly of the present invention. The heat dissipation device assembly 100 includes several fasteners 10 , a radiator 20 , a fan 30 and a heat pipe 40 .

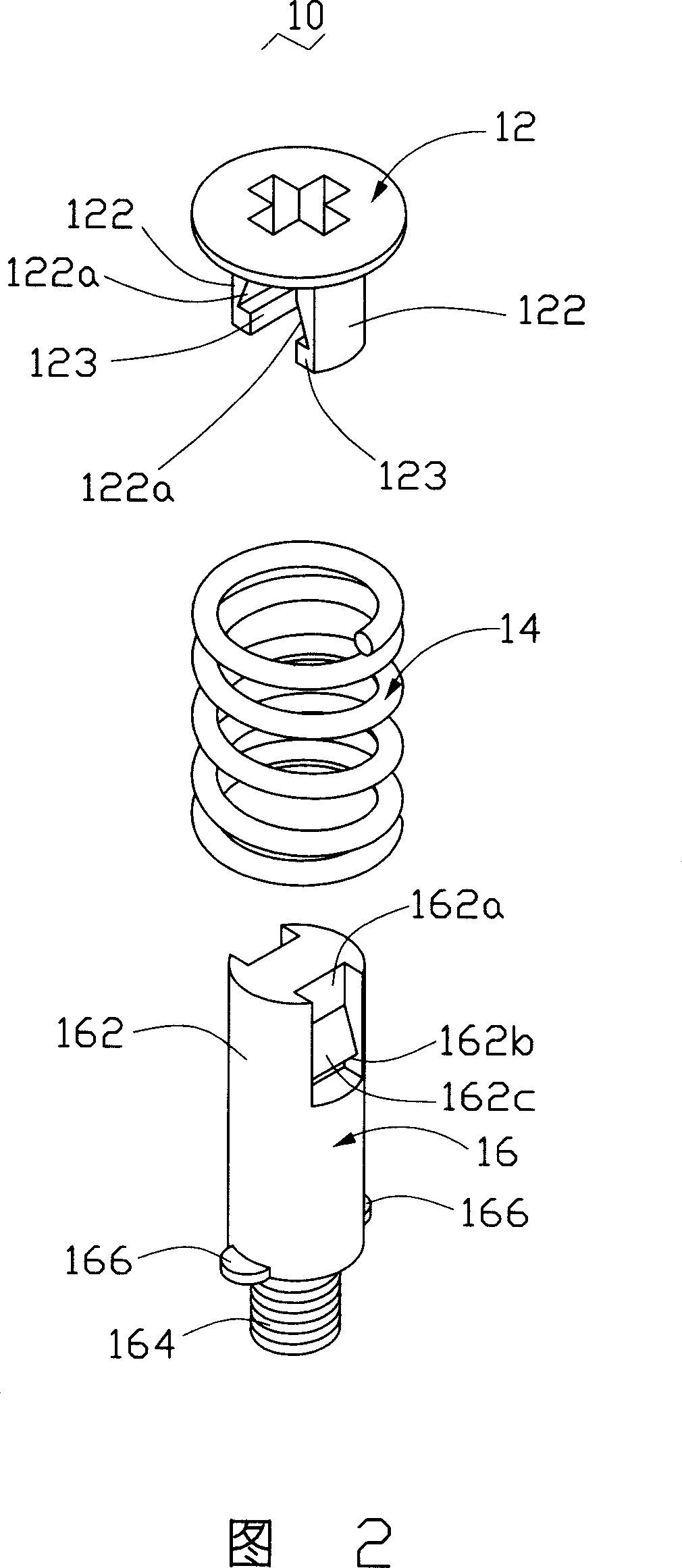

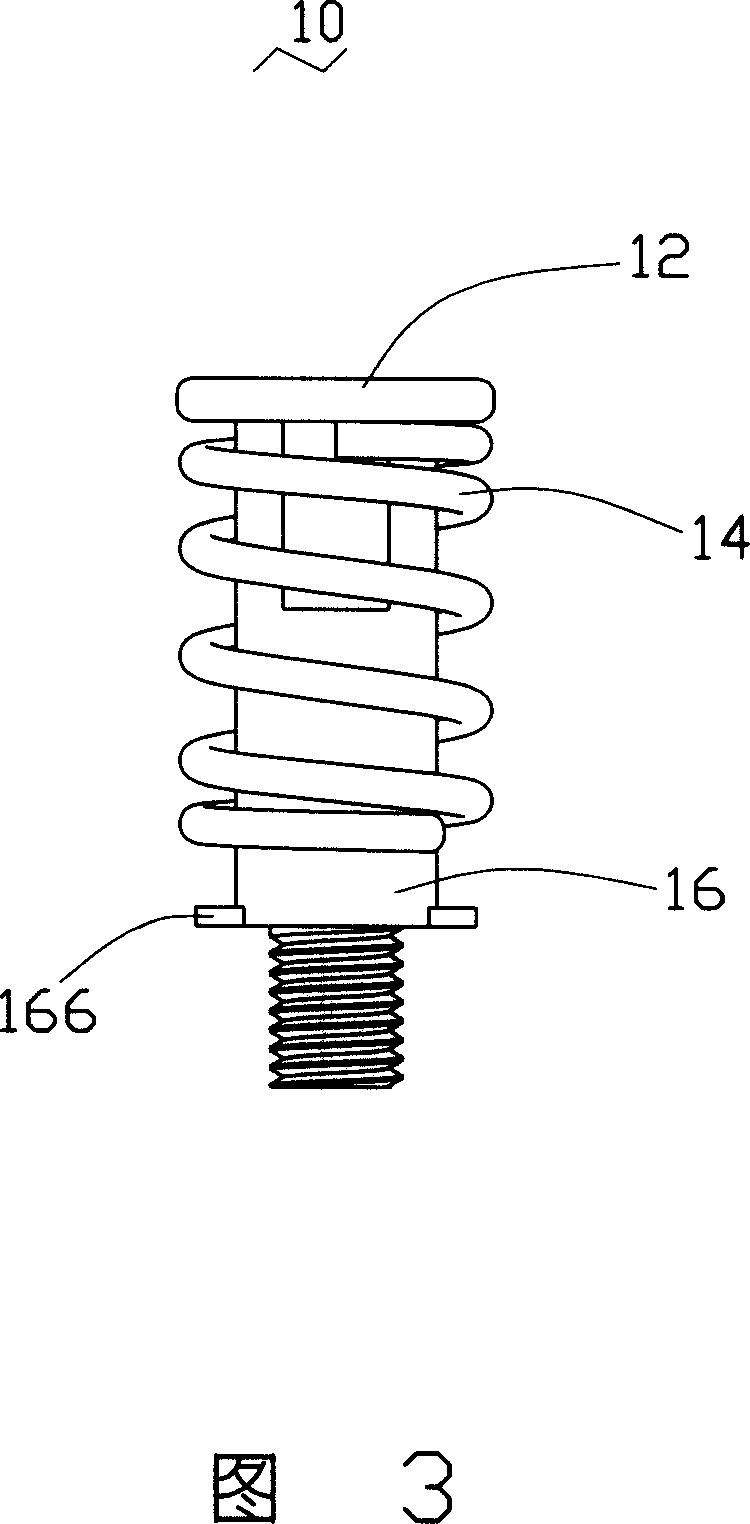

[0020] The heat sink 20 includes a base 22 and a plurality of cooling fins 24 . The fan 30 is located on one side of the base 22 . The fan 30 is a centrifugal fan. The cooling fins 24 are located at the air outlet of the fan 30 . The base 22 is made of metal materials such as copper, aluminum, aluminum alloy, etc., and the base 22 is thermally connected with a heating electronic component (not shown). Four corners of the base 22 are provided with a plurality of sleeves 222 for the fasteners 10 to pass through. Each buckle 10 includes a head 12 , an elastic body 14 and a rod 16 .

[0021] The heat pipe 40 connects the base 22 and the cooling fins 24 , and transfers the heat from the base 22 to the cooling fins 24 . The fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com