High-pressure fuel supply pump

A high-pressure fuel and supply pump technology, which is applied in the directions of fuel injection pumps, fuel injection devices, charging systems, etc., can solve the problems such as the decrease in the injection volume of the high-pressure fuel supply pump and the decrease in energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

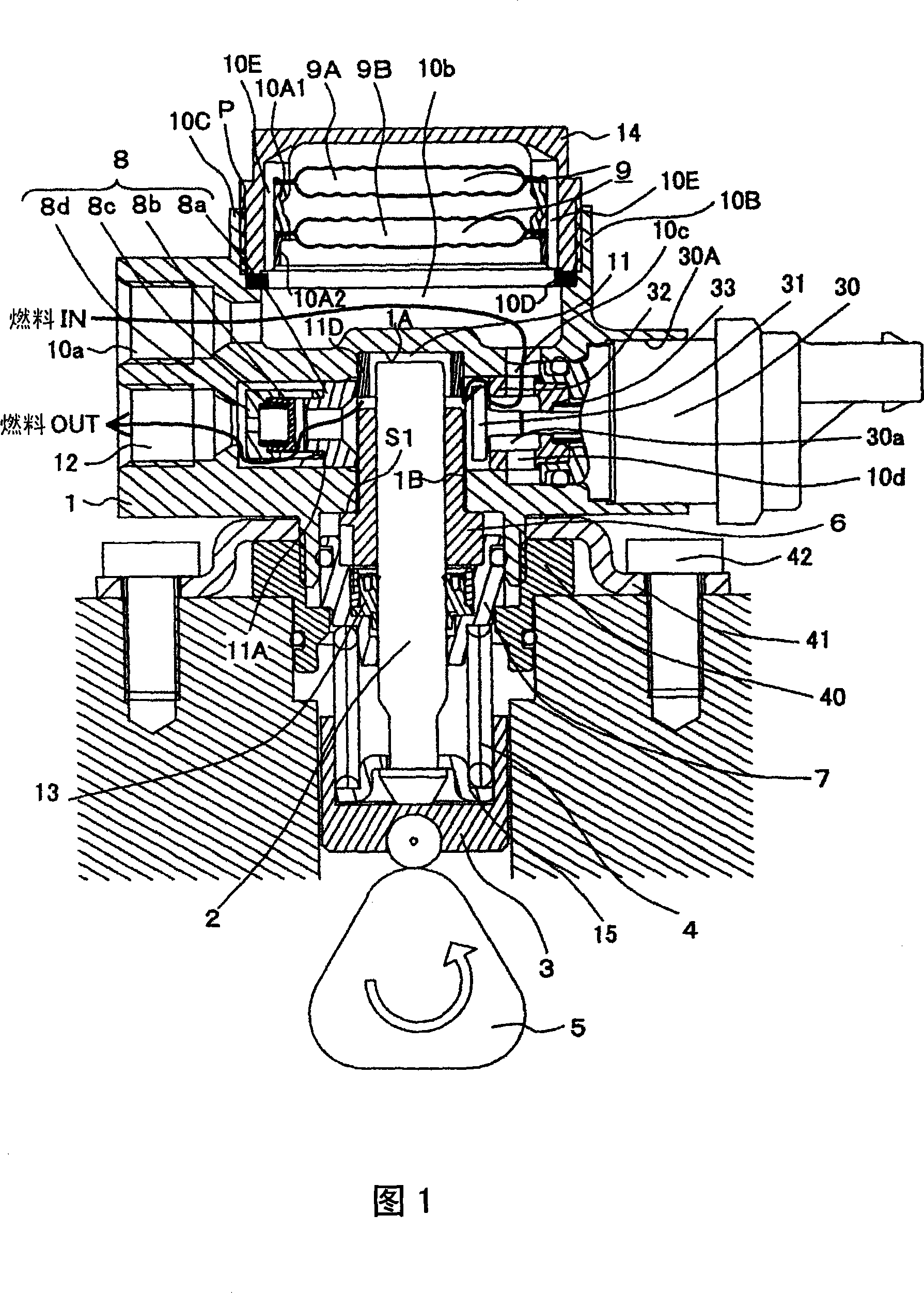

[0038] A first embodiment of the present invention will be specifically described based on FIGS. 1 to 3 . First, the structure and operation of the system will be described using the overall structure diagram of the system shown in FIG. 3 .

[0039] The portion surrounded by a dotted line represents the pump housing 1 of the high-pressure pump, and the mechanisms and parts indicated by the dotted line are integrally assembled in the pump housing 1 of the high-pressure pump.

[0040] The fuel in the fuel tank 20 is sucked up by the feed pump 21 and sent to the suction joint 10 a of the pump casing 1 through the suction pipe 28 . At this time, the suction fuel flowing to the pump housing 1 is regulated to a certain pressure at the pressure regulator 22 .

[0041] The fuel passing through the suction joint 10a reaches the suction port 30a of the electromagnetic suction valve mechanism 30 constituting the capacity variable mechanism via the pressure pulsation reducing mechanism 9...

Embodiment 2

[0119] Next, a second embodiment will be described based on FIG. 1 and FIGS. 8 to 18 .

[0120] First, a specific structure of the safety valve mechanism B200 will be described with reference to FIGS. 8 to 10 .

[0121] The safety valve mechanism B200 consists of the following parts: a safety valve body B206 integrated with the safety valve seat B201, a safety valve B202, a safety pressing piece B203, a safety spring B204, and a safety spring regulator B205. The safety valve mechanism B200 is assembled outside the pump casing 1 as an auxiliary component, and then fixed to the pump casing 1 by press-fitting.

[0122]First, insert the safety valve B202, safety pressing piece B203, and safety spring B204 into the safety valve body B206 in sequence, and press and fix the safety spring adjuster B205 to the safety valve body B206. The setting load of the safety spring B204 is determined by the fixed position of the safety spring adjuster B205. The opening pressure of the safety va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com