Ceramic packing member used for SMD crystal resonator and manufacturing technique thereof

A crystal resonator and ceramic packaging technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of high production cost, complex product design, and numerous processes, and achieve simplified co-fired ceramics process , The effect of improving the electrical performance of the product and reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

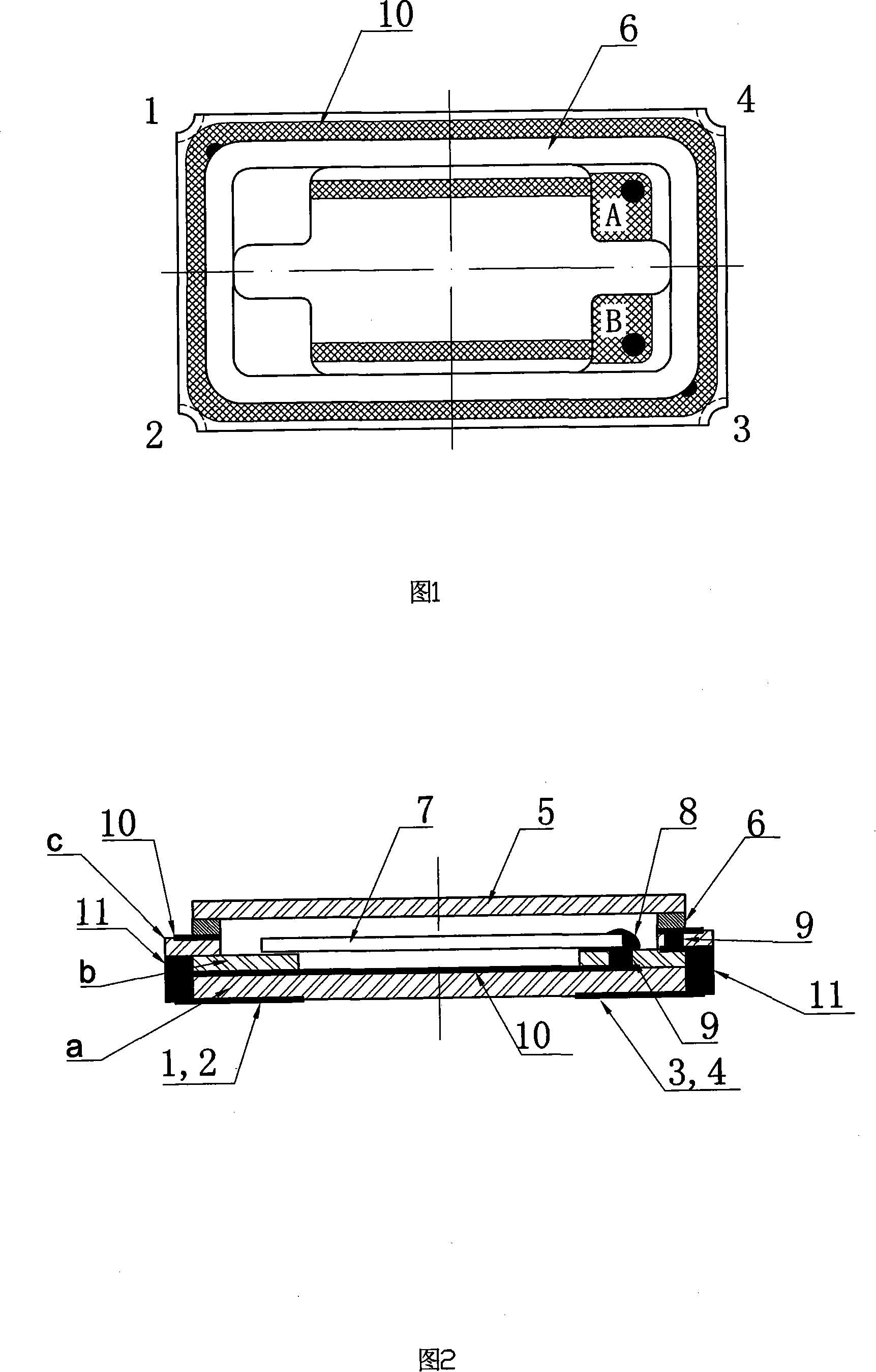

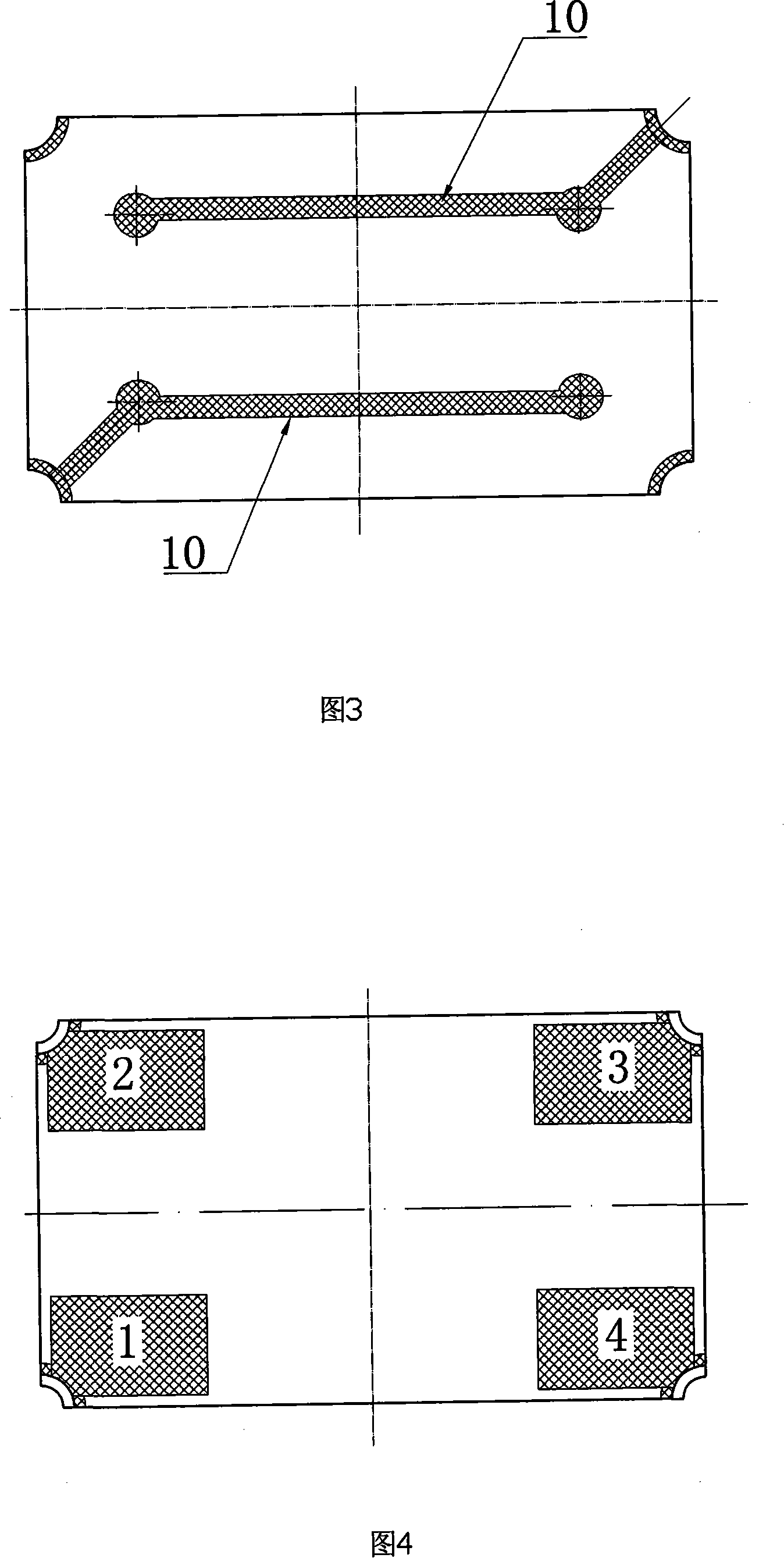

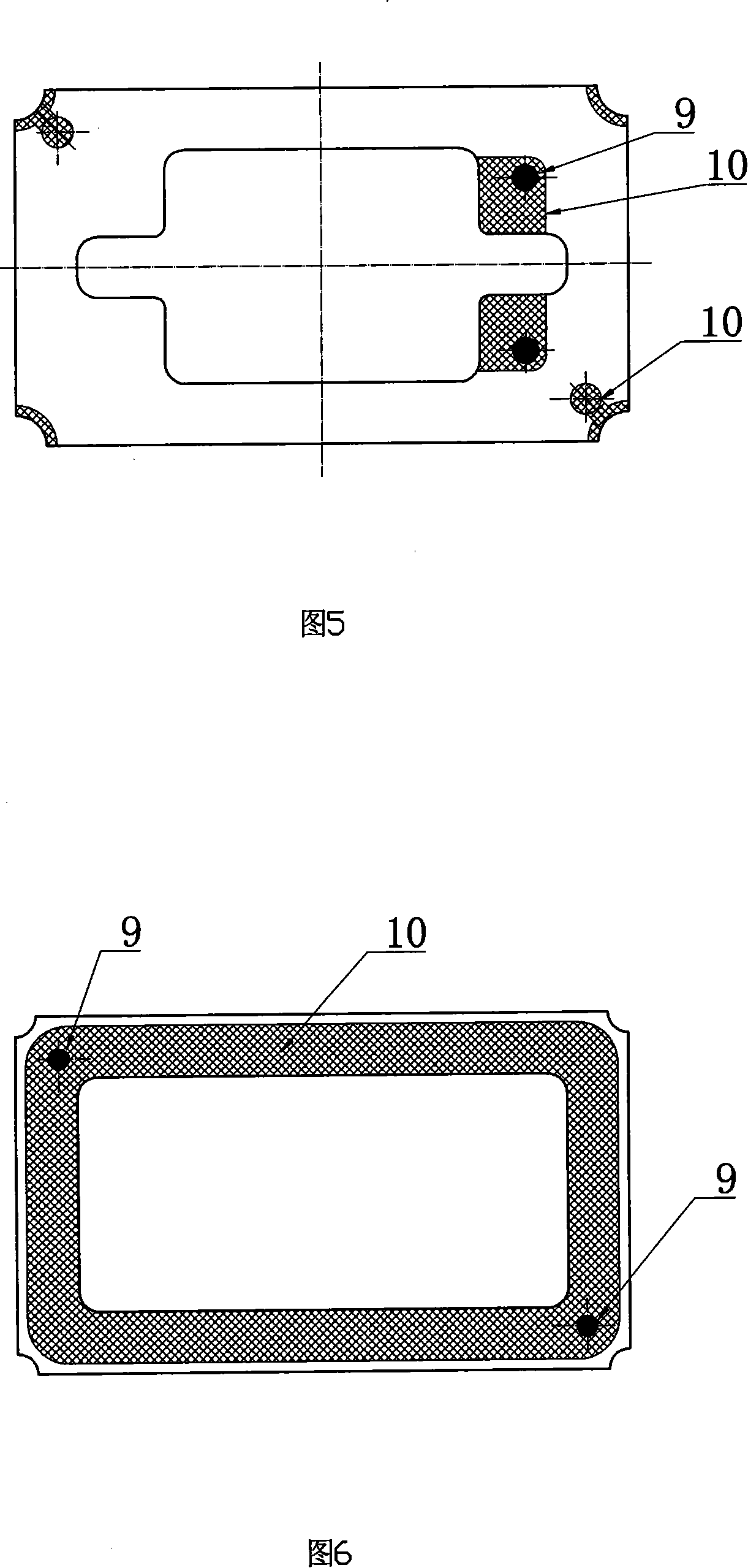

[0042] With reference to Fig. 7 to Fig. 16, the present invention is implemented like this:

[0043] A ceramic package for SMD crystal resonators, comprising a bottom pad 1 and a bottom pad 2, a co-fired ceramic layer and a ceramic cover plate 3, and the co-fired ceramic layer is composed of a stacked first co-fired ceramic layer a Composed with the second co-fired ceramic layer b, a ceramic cover plate 3 is arranged on the top of the second co-fired ceramic layer b, and a printed support plate 3 is provided on the upper side of the first co-fired ceramic layer a. The electrodes on the resonant crystal 4 are connected to the pads on the bottom surface through the via holes on the first layer, and the bosses include a supporting boss C for supporting functions and two supporting conductive pads for conducting and supporting functions. The main function of the bosses A, B, and the supporting boss C is to provide a vibration space for the resonant crystal 4, and the outer periphe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com