Technique for extracting low phenanthrene and anthracene oil from distillation of coal oil and anthracene oil

A technology of coal tar and low phenanthrene, applied in the field of extracting intermediates, can solve the problems of long total reaction time, product quality needs to be improved, and low processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

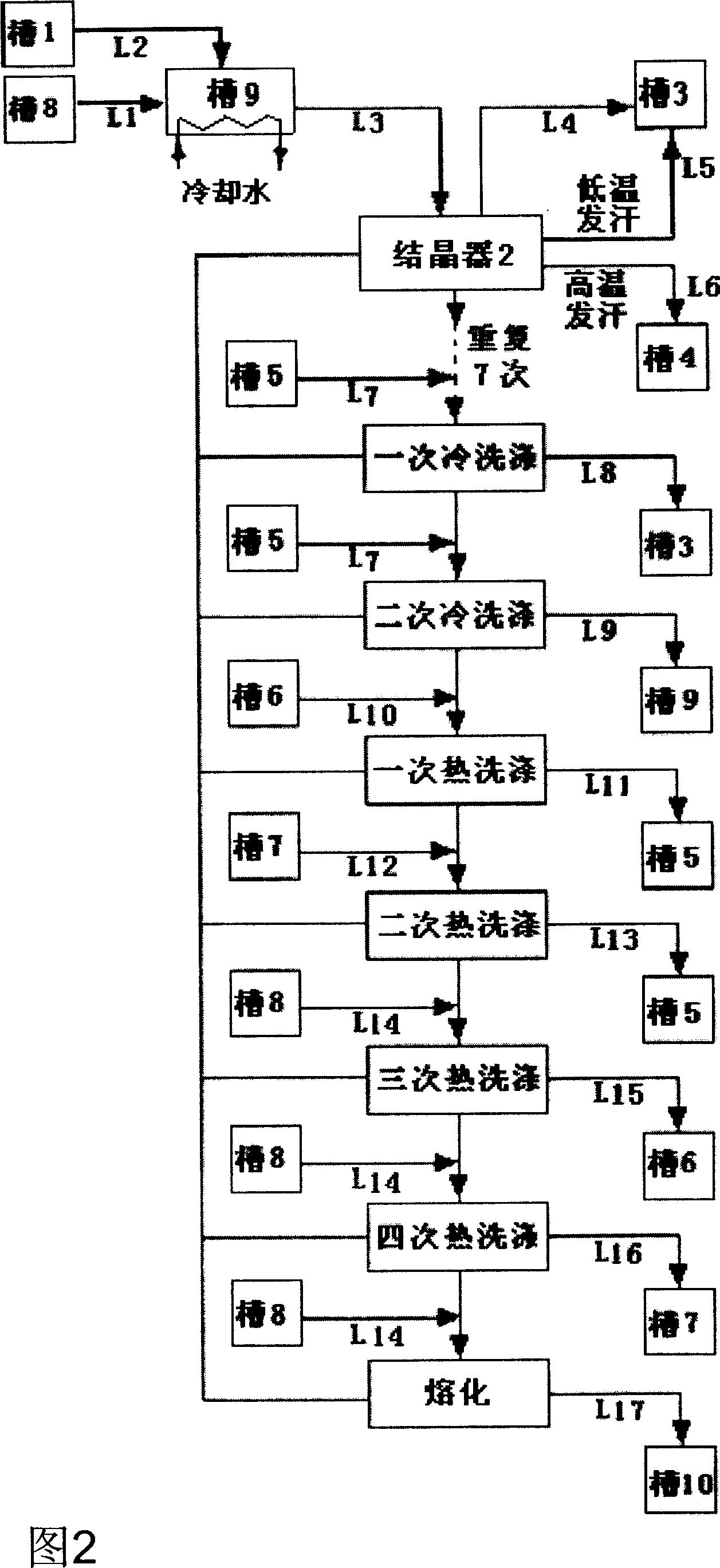

[0038] According to the process disclosed in the "Summary of the Invention" of the present invention, the process and the equipment used are described in detail below:

[0039] First, please refer to Figure 1. The raw material - coal tar anthracene oil fraction A and solvent B with high xylene content are prepared in a certain proportion to form a mixed solution in a sealed crystallization container. After eight stacking crystallizations and two cold washing , four times of hot washing, and one melting of the four major processes. All the extracted low-phenanthrene oils are in a molten state, and are discharged from the crystallizer into the final product storage tank through pipelines. %; the carbazole content is 4-8%; the phenanthrene content is 0.3-1%; the total extraction process time is 60.5-75.5 hours; the processing capacity of anthracene oil fraction is 5.0-5.2 tons / hour.

[0040] The above-mentioned solvent B is a special solvent disclosed in the patent application n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com