Method for producing low-magnesium battery-stage lithium carbonate from lithium sulfate solution

A lithium sulfate and lithium carbonate technology, applied in carbonate preparations and other directions, can solve problems such as the inability to produce low-magnesium battery-grade lithium carbonate, and achieve the effects of solving the problem of soda ash impurity removal, simple production process and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

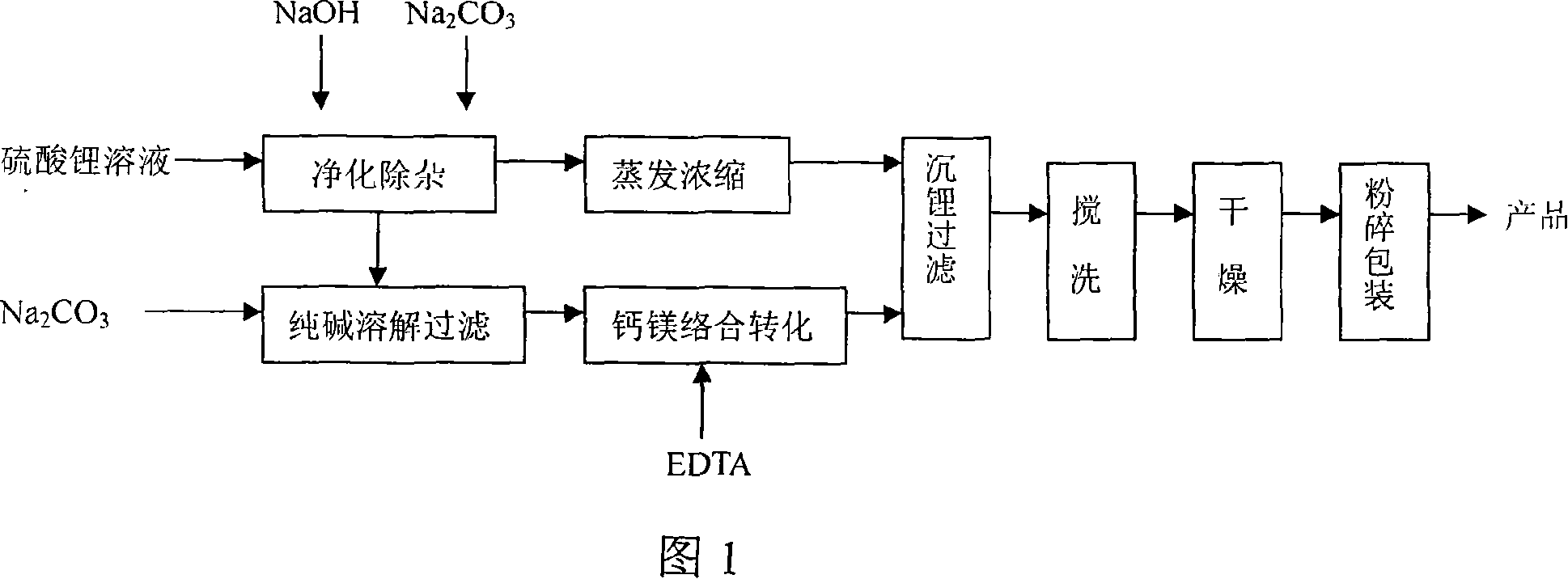

[0038] Present embodiment 1 method comprises the following steps (referring to Fig. 1)

[0039] 1. Put Li 2 6.0m with an O content of 20g / L 3 Lithium sulfate solution is heated to 70°C, add 10kg of sodium hydroxide, react for 10 minutes, the pH value reaches 10, then add Na2 CO 3 8kg, react for 30 minutes, detect CO 3 2- up to 0.5g / L, filtered to obtain purified lithium sulfate solution and purification residue, and measured the purified lithium sulfate solution Ca 2+ =0.0025g / L, Fe 3+ =0.0003g / L, Mg 2+ =0.0018g / L; Then the purified lithium sulfate solution is evaporated and concentrated to 60g / L, and filtered to obtain the clean lithium sulfate solution;

[0040] 2. Put 1.4m 3 The temperature of the condensed water was raised to 80°C, then 420kg of soda ash was added, stirred until it was completely dissolved, then 60kg of purified slag was added, left to stand for 20 minutes and filtered to obtain a purified soda ash solution, and the Na 2 CO 3 =298g / L, Ca 2+ =0.00...

Embodiment 2

[0044] Present embodiment 2 method comprises the following steps (referring to Fig. 1):

[0045] 1. Put Li 2 5.65m with an O content of 25g / L 3 Heat up the lithium sulfate solution to 80°C, add 12kg of sodium hydroxide, react for 15 minutes, adjust the pH value to 11, add Na 2 CO 3 10kg, react for 30 minutes, detect CO 3 2- up to 0.4g / L, filtered to obtain purified lithium sulfate solution and purification slag, and measured the purified lithium sulfate solution Ca 2+ =0.001g / L, Fe 3+ =0.00025g / L, Mg 2+ =0.0015g / L; Then the purified lithium sulfate solution is evaporated and concentrated to 55g / L, and filtered to obtain the lithium sulfate solution;

[0046] 2. Put 1.65m 3 The temperature of the condensed water is raised to 85°C, then 500kg of soda ash is added, stirred until it is completely dissolved, then 30kg of purified slag is added, left to stand for 30min (minutes) and filtered to obtain a purified soda ash solution, and the Na 2 CO 3 =305g / L, Ca 2+ =0.0035g...

Embodiment 3

[0050] The present embodiment comprises the following steps (see Fig. 1):

[0051] 1. Put Li 2 4.05m with an O content of 27g / L 3 Heat up the lithium sulfate solution to 90°C, add 9kg of sodium hydroxide, react for 12 minutes, adjust the pH value to 9, add Na 2 CO 3 6kg, react for 30 minutes, detect CO 3 2- up to 0.3g / L, filter to obtain purified lithium sulfate solution and purification residue, and measure the purified lithium sulfate solution Ca 2+ =0.0036g / L, Fe 3+ =0.00035g / L, Mg 2+ =0.004g / L; Then the purified lithium sulfate solution is evaporated and concentrated to 65g / L, and filtered to obtain the pure lithium sulfate solution;

[0052] 2. Put 1.35m 3 The temperature of the condensed water was raised to 90°C, then 400kg of soda ash was added, stirred until it was completely dissolved, then 45kg of purified slag was added, left to stand for 40 minutes and filtered to obtain a purified soda ash solution, and the Na 2 CO 3 =295g / L, Ca 2+ =0.0025g / L, Mg 2+ =0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com