Hydrogen generator

A generator and hydrogen technology, applied in the direction of hydrogen production, etc., can solve the problems of complicated device system structure, inconvenient operation, difficult catalyst replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

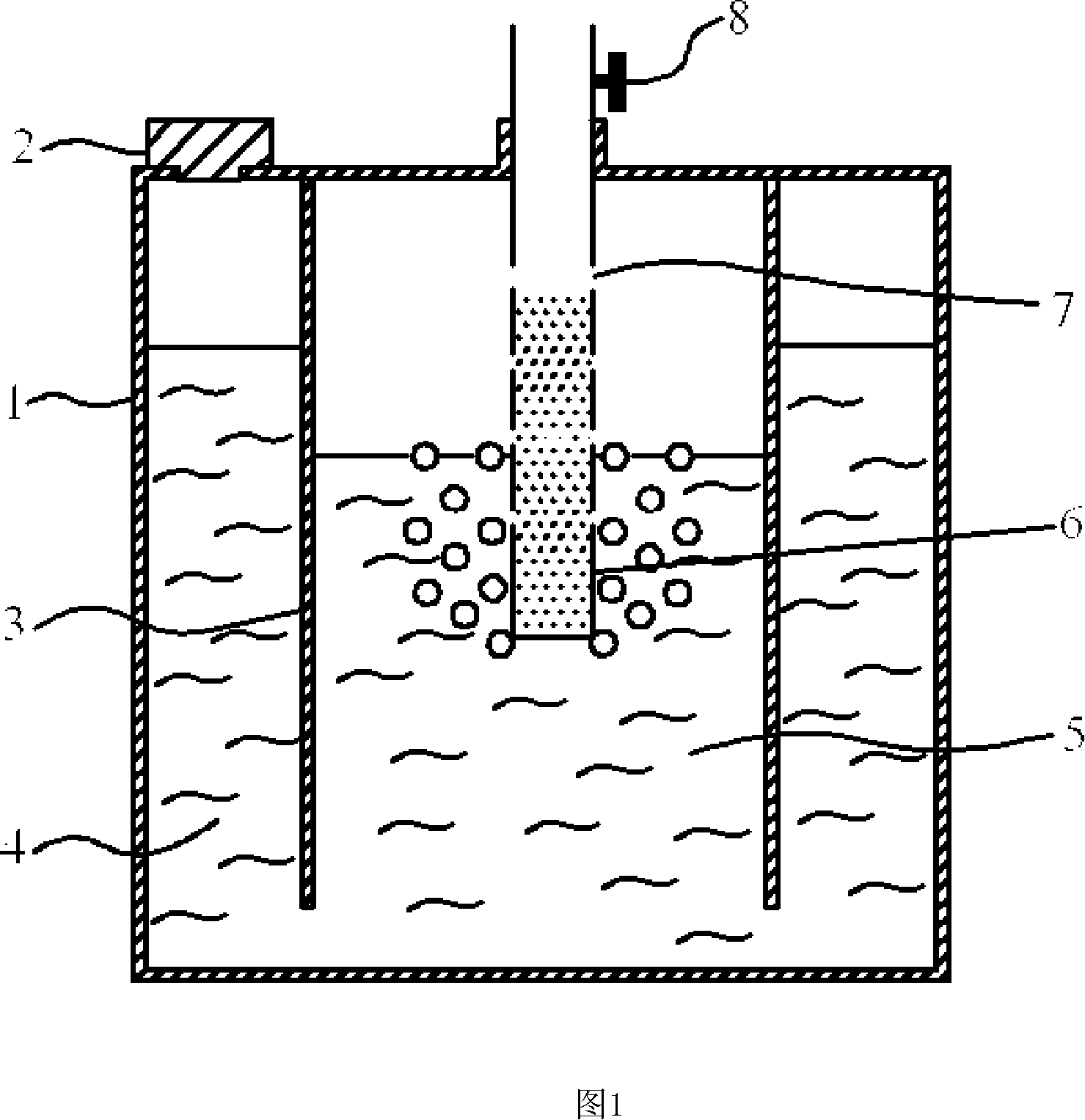

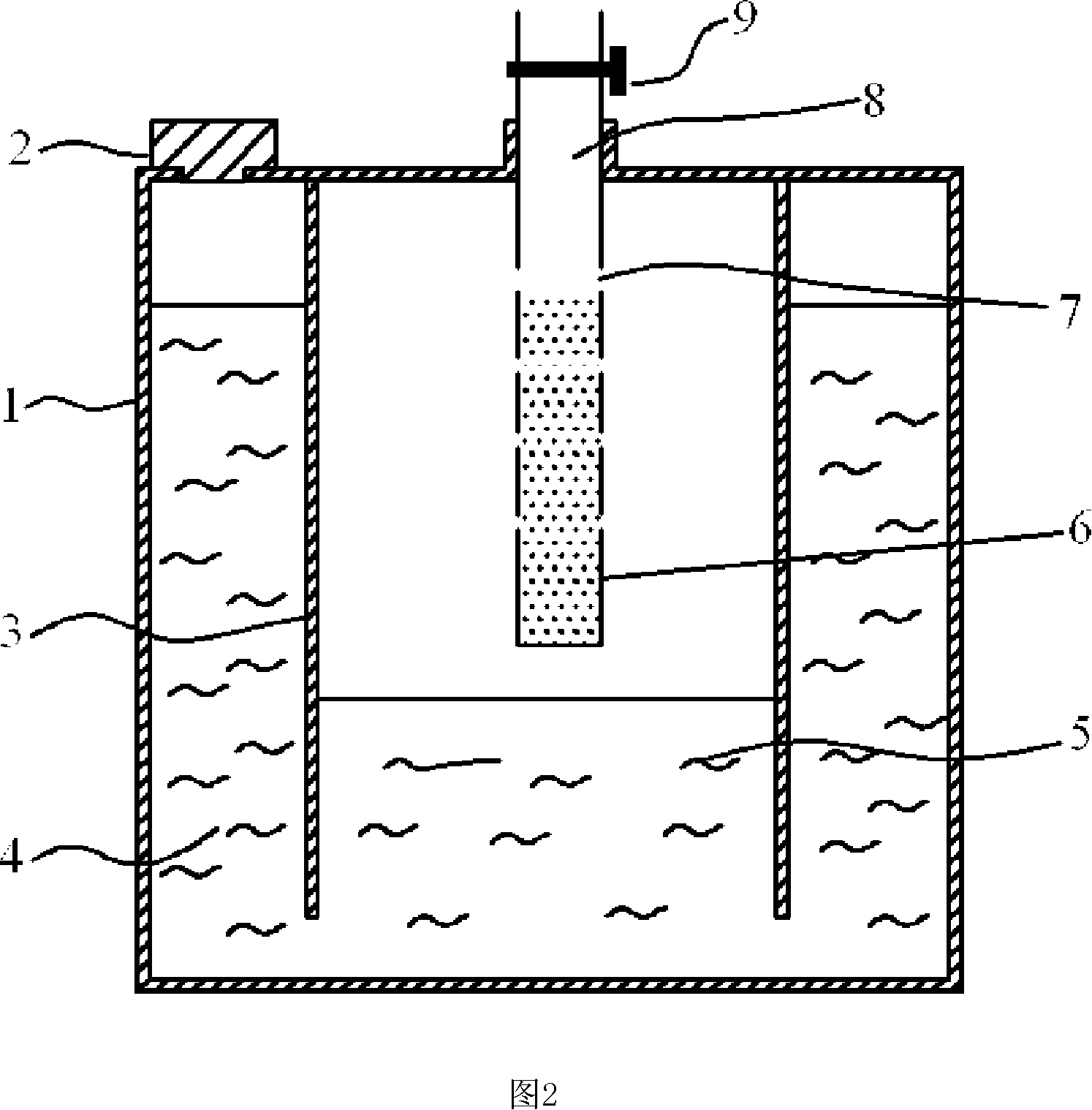

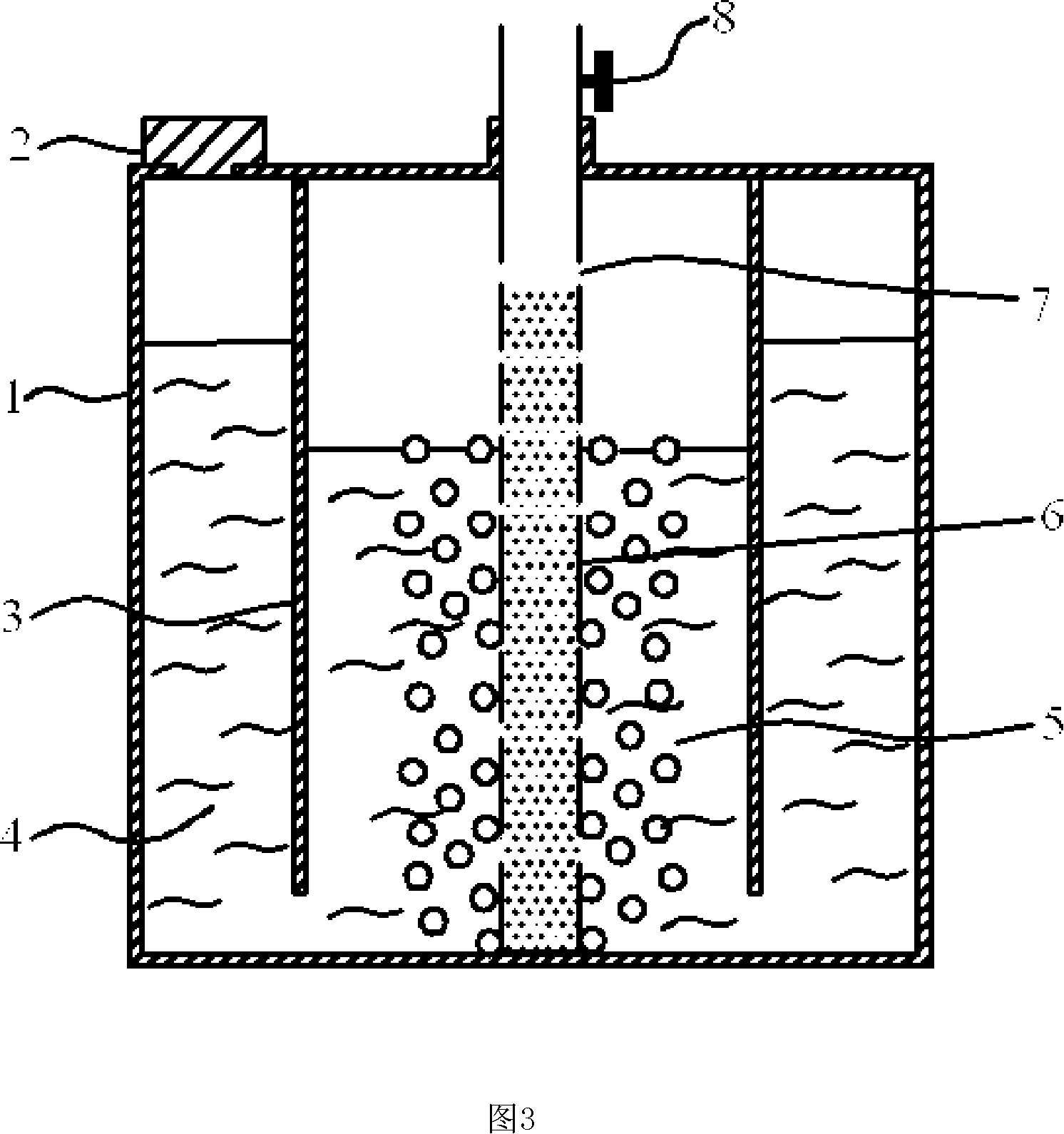

[0022] A kind of hydrogen generator, as shown in Figure 1, the hydrogen generator of the present invention comprises the fuel tank 1 that is provided with fuel inlet and outlet 2 and the catalytic reactor 6 that is fixed on the fuel tank 1, and specific structure is as follows:

[0023] The inner shell 3 located in the fuel tank 1 separates the fuel tank 1 into two parts: the inner chamber, the fuel reaction chamber 5, and the outer chamber, the fuel storage chamber 4; there is a gap between the lower end of the inner shell 3 and the bottom of the fuel tank; the catalytic reaction The device 6 is located in the fuel reaction chamber 5 .

[0024] Catalytic reactor 6 is made of polycarbonate, is provided with hole 7 on the wall, and the shape of hole 7 can be geometric figures such as circle, square, triangle, star, and the upper limit of pore size is standard that catalyst can not leak out, and lower limit Criteria for easy access to fuel solution. The proportion of the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com