Lamp tube driving circuit

A technology for driving circuits and lamp tubes, which is applied to circuits, discharge lamps, electric light sources, etc., and can solve the problems of process complexity and manufacturing cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and effects of the lamp drive circuit proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. , as detailed below.

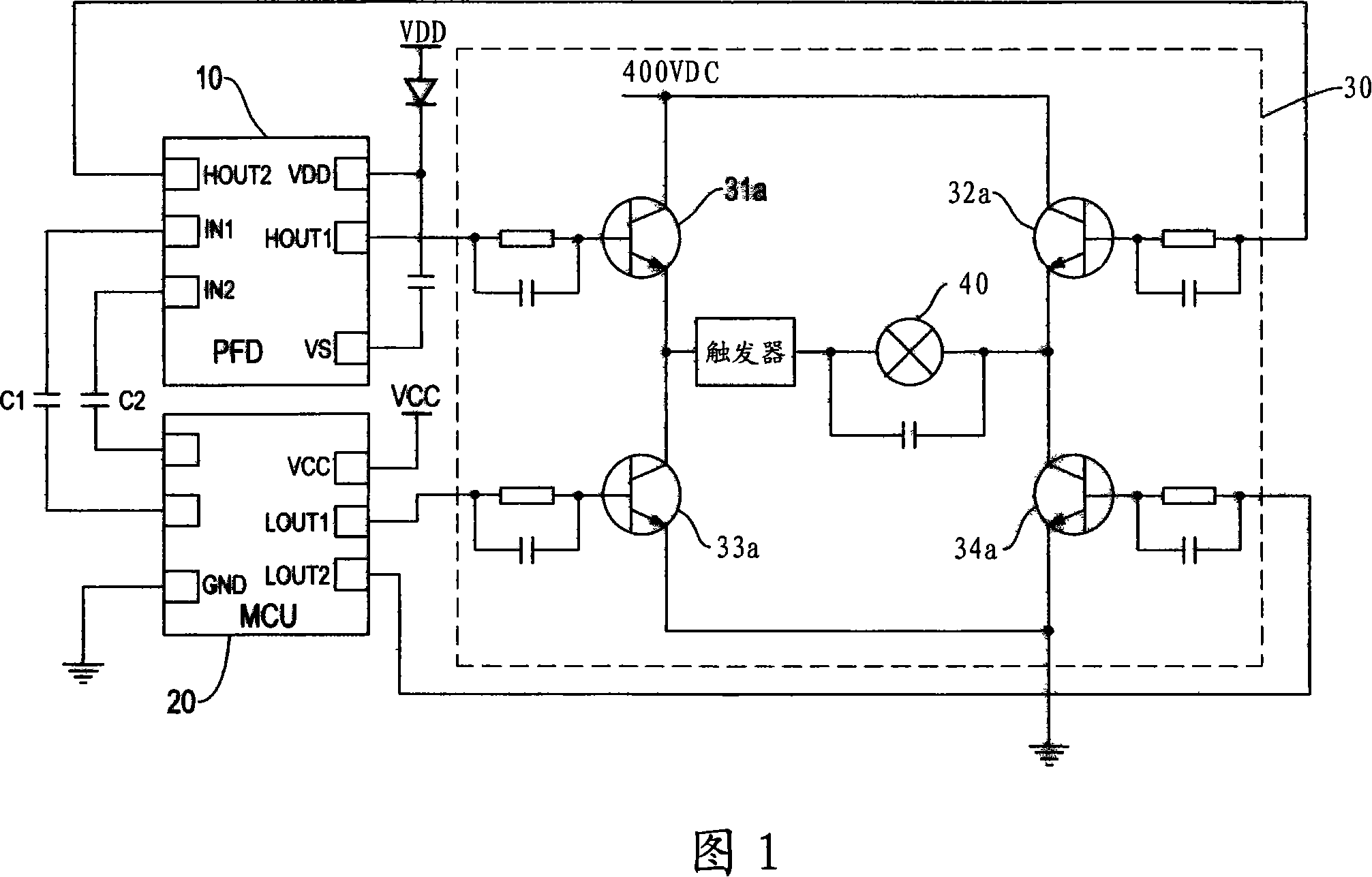

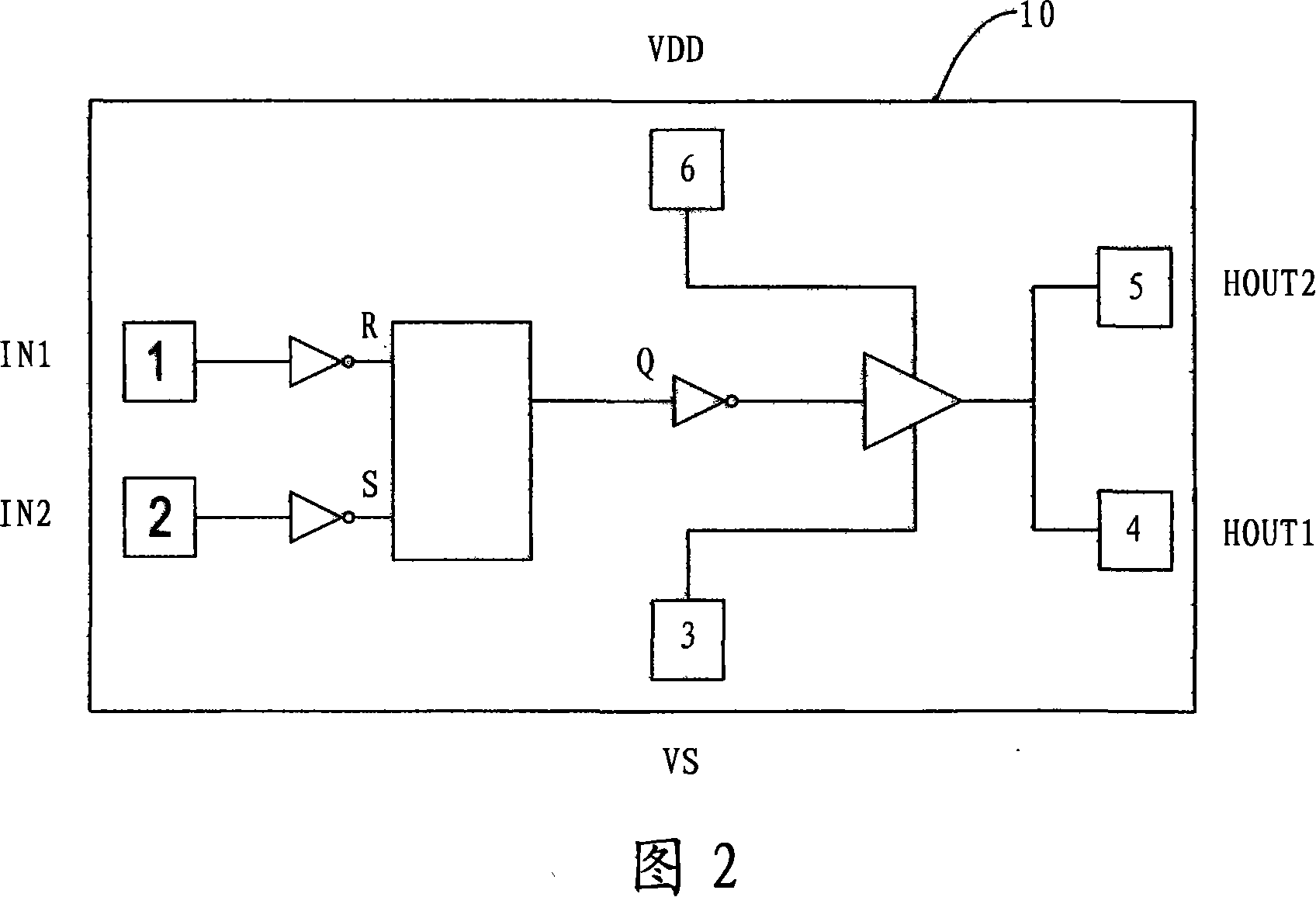

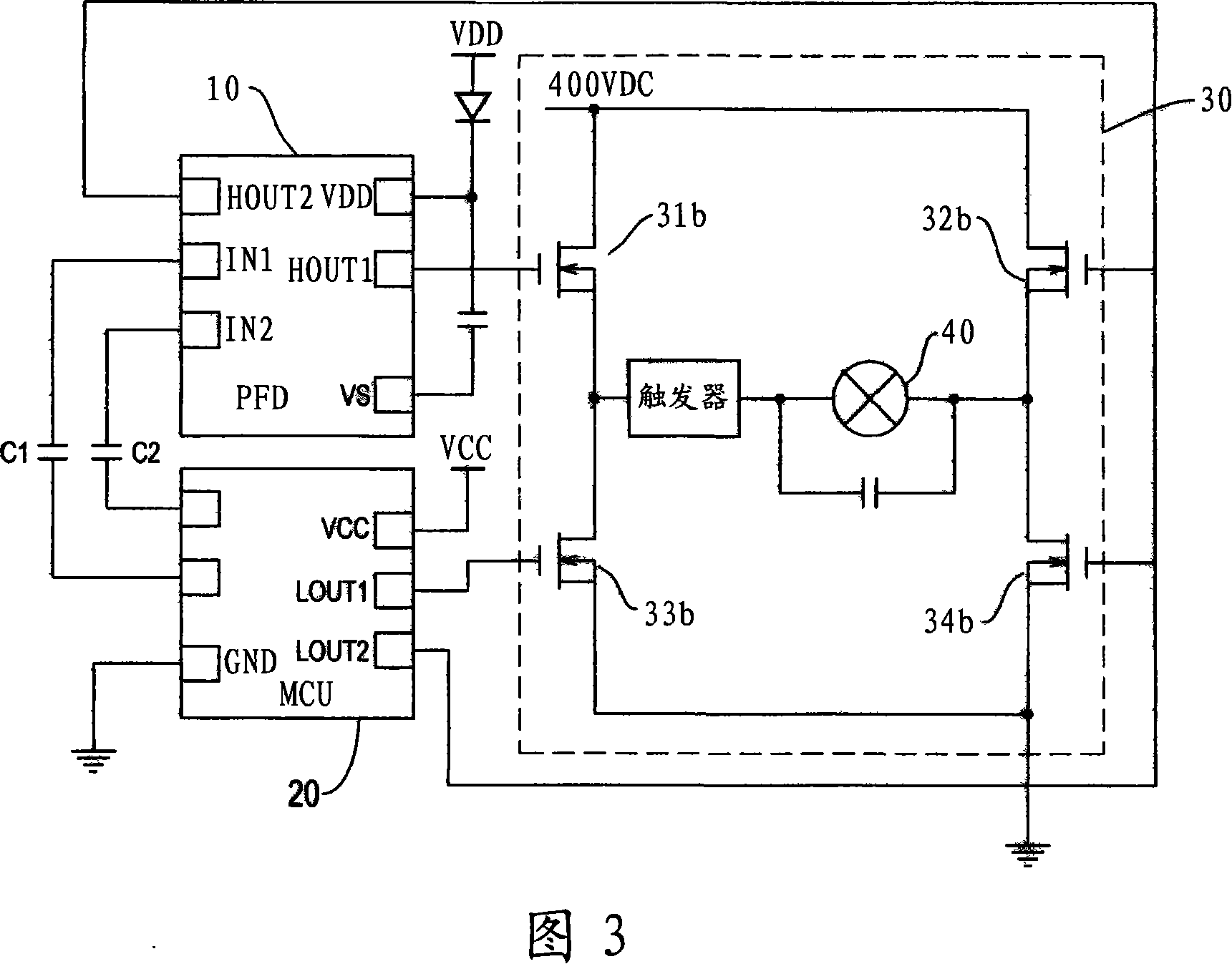

[0053] Please refer to Fig. 1, a floating power driver 10 and a microprocessing unit (MCU) 20 coupled to the floating power driver are used in the lamp driving circuit of the present invention, and a driving unit 30 is jointly controlled by the two. The driving unit 30 is connected to two ends of a lamp tube 40 . The micro-processing unit 20 can also be a general-purpose pulse width modulation control circuit (eg TL494CD), and the micro-processing unit 20 can be designed and developed as an application-specific IC (ASIC) in order to reduce costs.

[0054] In this embodiment, the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com