Method for preparing polyurethane-imide permeable vaporizing aromatic/alkane separating membrane

A technology of polyurethane imide and pervaporation, which is applied in the purification/separation of hydrocarbons, chemical instruments and methods, organic chemistry, etc., and can solve the problems of complex process, high energy consumption, limited concentration range of auxiliary reagents and feed materials, etc. , to achieve the effects of reduced energy consumption, good separation performance, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

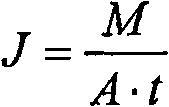

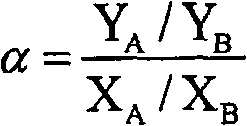

Method used

Image

Examples

Embodiment 1

[0027] 1) Synthesis of polyurethane-imide prepolymer

[0028] Add polyethylene adipate glycol (PEA) 10g (before use through 110 ℃ dehydration treatment under reduced pressure) and diphenylmethane diisocyanate ( MDI) monomer (the number of moles of MDI is twice that of PEA), make it react for 1.5 hours under the conditions of vigorous stirring and heating in a water bath at 80°C to obtain an MDI-capped prepolymer, and add It was diluted with 7ml of N,N-dimethylformamide (DMF) (purified by distillation under reduced pressure before use). Then add 1.1g pyromellitic dianhydride (purified by sublimation under reduced pressure before use) and other 7ml DMF to the solution of the end-capped prepolymer with polyethylene adipate diol equimolar equivalent, and The reaction temperature was raised to 85° C. for 2 hours to carry out the chain extension reaction, and finally a viscous polyurethane-imide prepolymer solution was obtained.

[0029] 2) Preparation of polyurethane-imide film ...

Embodiment 2

[0035] 1) Synthesis of polyurethane-imide prepolymer

[0036]Add polyethylene adipate glycol (PEA, molecular weight 1000g / mol) 10g (dehydration under reduced pressure at 110°C before use) and 2 , 4-toluene diisocyanate (TDI, isomerization ratio 80 / 20) monomer (the molar number of TDI is 2 times that of PEA), make it react under the conditions of vigorous stirring and 65 ℃ water bath heating for 2 hours, obtain TDI seal The end-capped prepolymer was added to the end-capped prepolymer by adding 7ml of N,N-dimethylformamide (DMF) (purified by vacuum distillation before use) to dilute it. Then add 1.1g pyromellitic dianhydride (purified by sublimation under reduced pressure before use) and other 7ml DMF to the solution of the end-capped prepolymer with polyethylene adipate diol equimolar equivalent, and The reaction temperature was raised to 95° C. for 3 hours to carry out the chain extension reaction, and finally a viscous polyurethane-imide prepolymer solution was obtained.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

| separation factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com