Manufacture process of high precision alloy fled rheostat

An alloy resistor, high-precision technology, applied in resistors, resistor manufacturing, circuits, etc., can solve the problem of difficulty in ensuring the accuracy of the resistance value of alloy chip resistors, size deviation of alloy chip resistors, and different lengths of alloy chip resistors. problems, to achieve the effect of improving production yield, improving quality stability, and reducing punching and shearing burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment that the present invention adopts will be further described by the following embodiments and accompanying drawings:

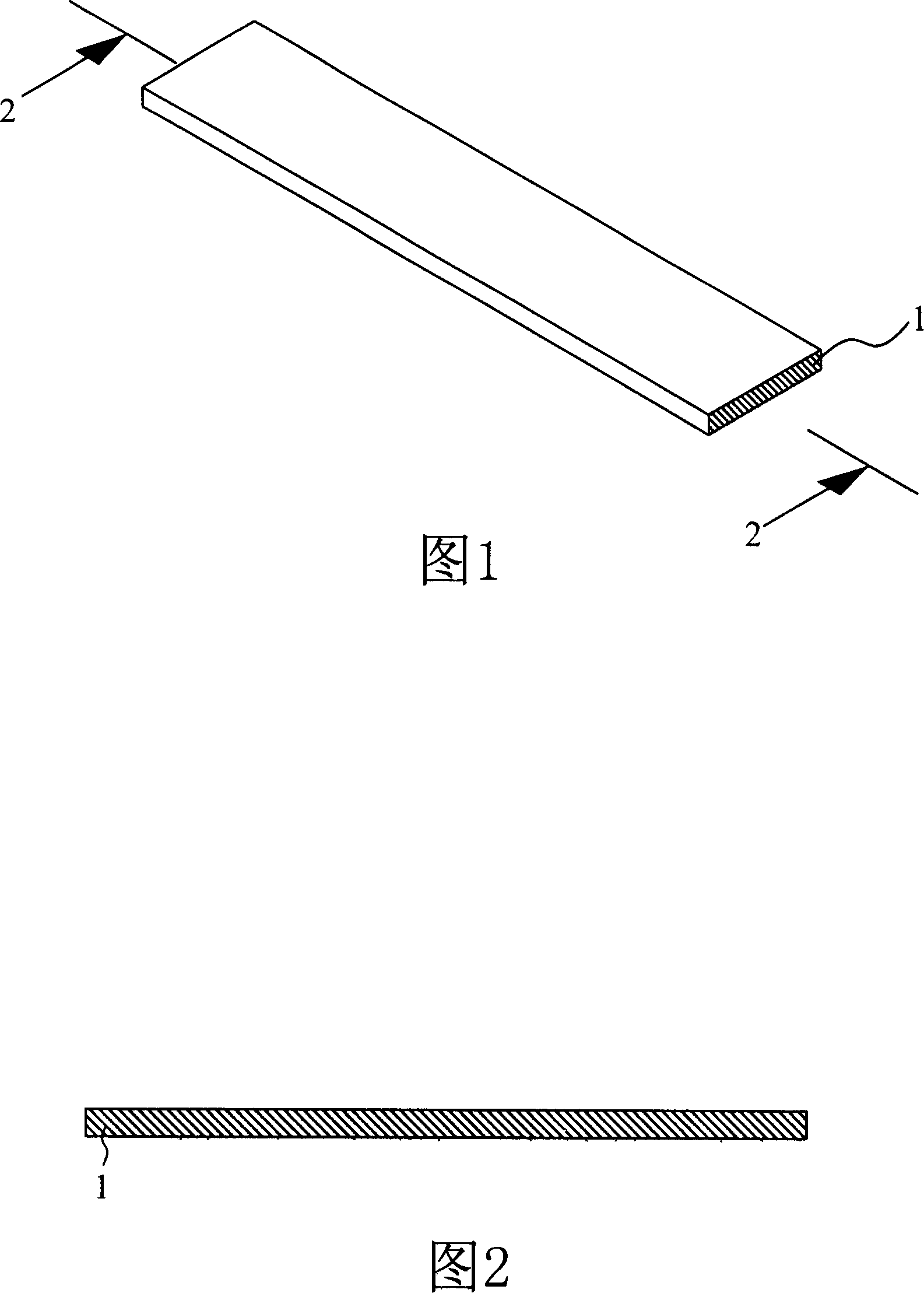

[0028] Please refer to FIG. 1 , which shows a perspective view of the first alloy plate prepared in the present invention. Fig. 2 is a cross-sectional view of section 2-2 in Fig. 1; the alloy plate 1 is formed by an alloy plate in the form of an extended strip, so it has a length extending direction, and the selection of its material and the determination of its thickness are based on the requirements Depending on the resistance value, for example, the material of the alloy plate can be nickel, chromium, manganese, aluminum, copper and other alloy plates.

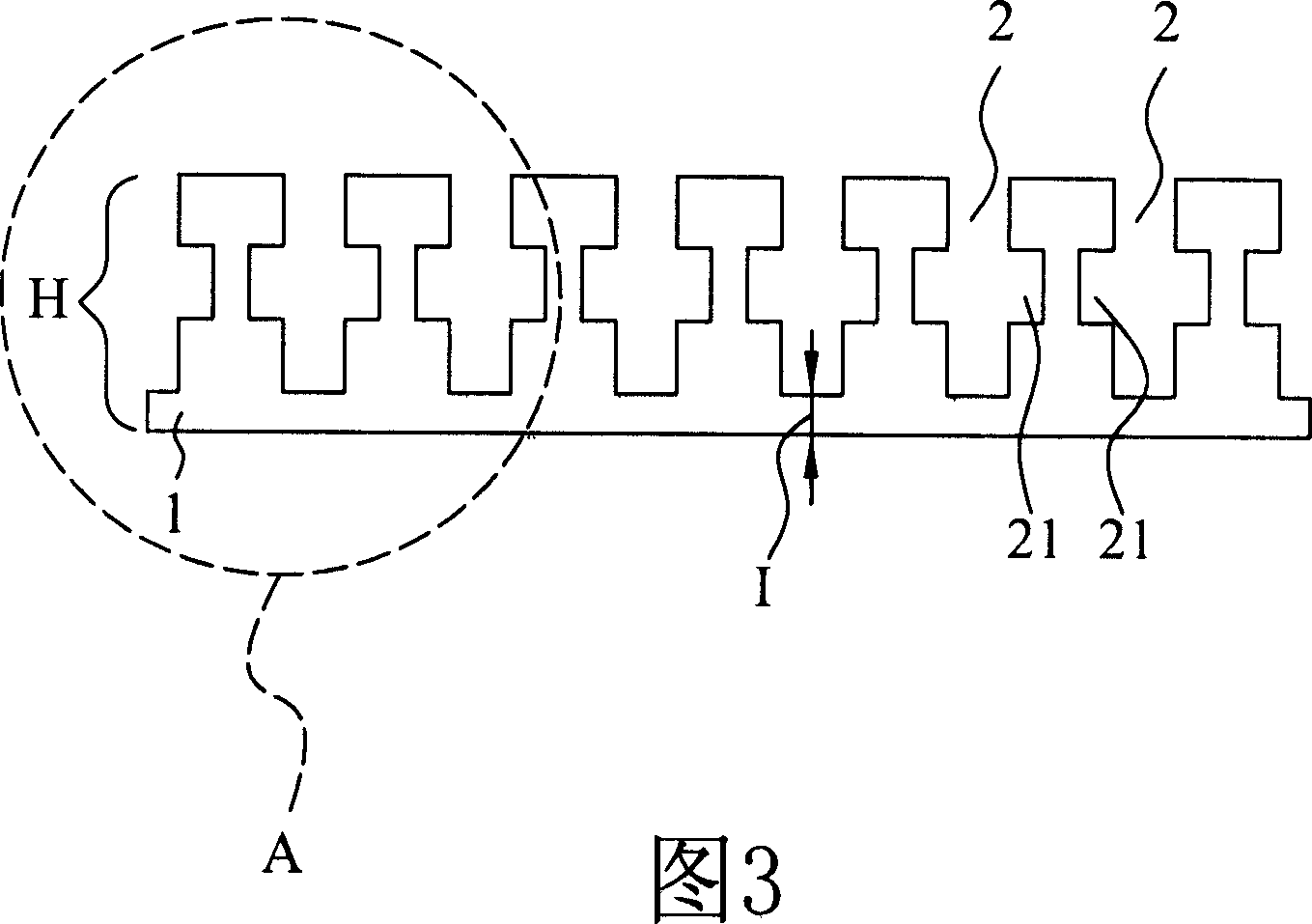

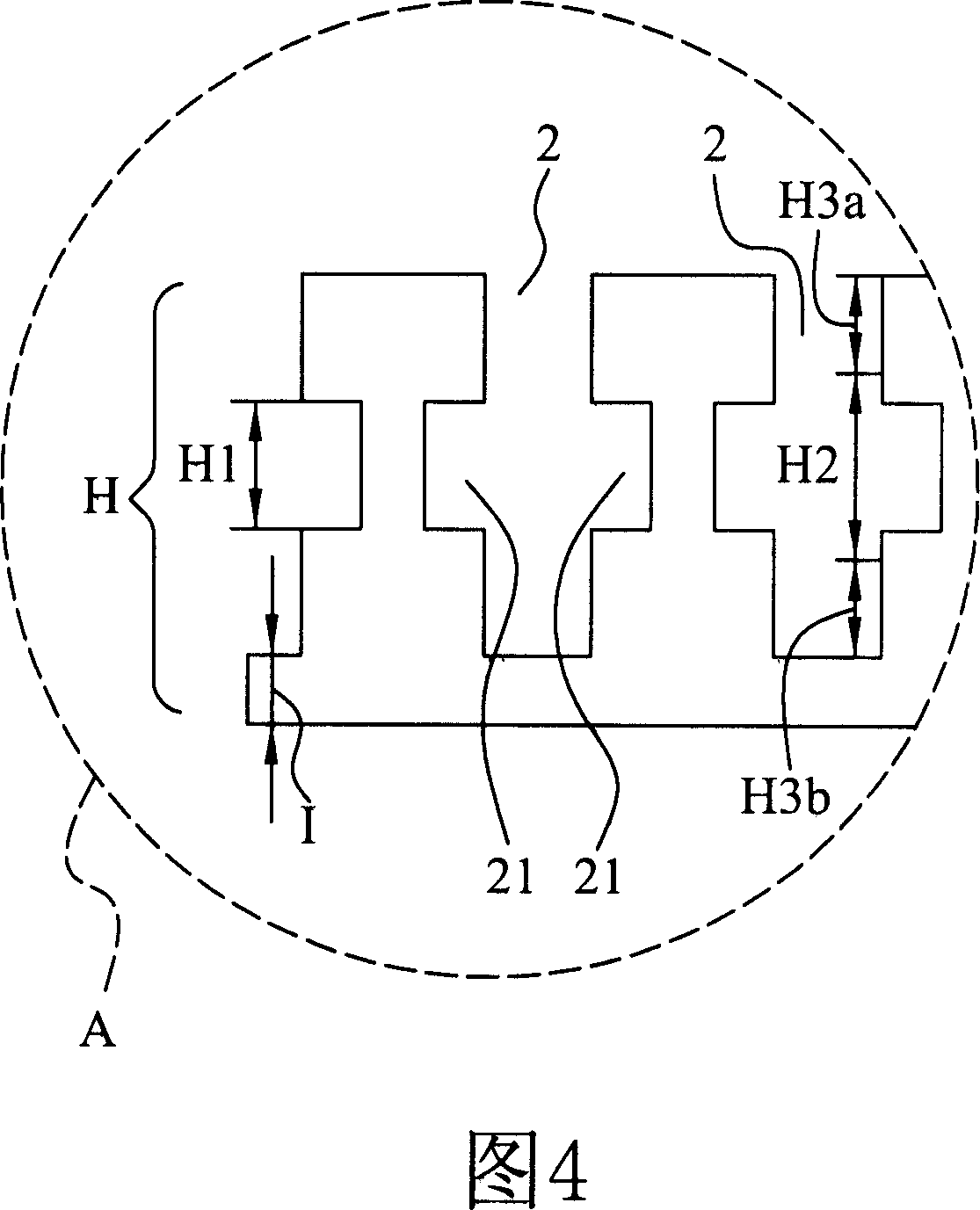

[0029] Please refer to Fig. 3 and Fig. 4. Fig. 3 and Fig. 4 show the schematic diagram and the enlarged view of some components after the alloy plate is stamped according to the required resistance value of the present invention. As shown in the figure, according to the require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com