Internal combustion engine providing a phase of scavenging burned gases

A technology for burning exhaust gas and internal combustion engines, which is applied to combustion engines, internal combustion piston engines, mechanical equipment, etc., and can solve problems such as damaging engine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

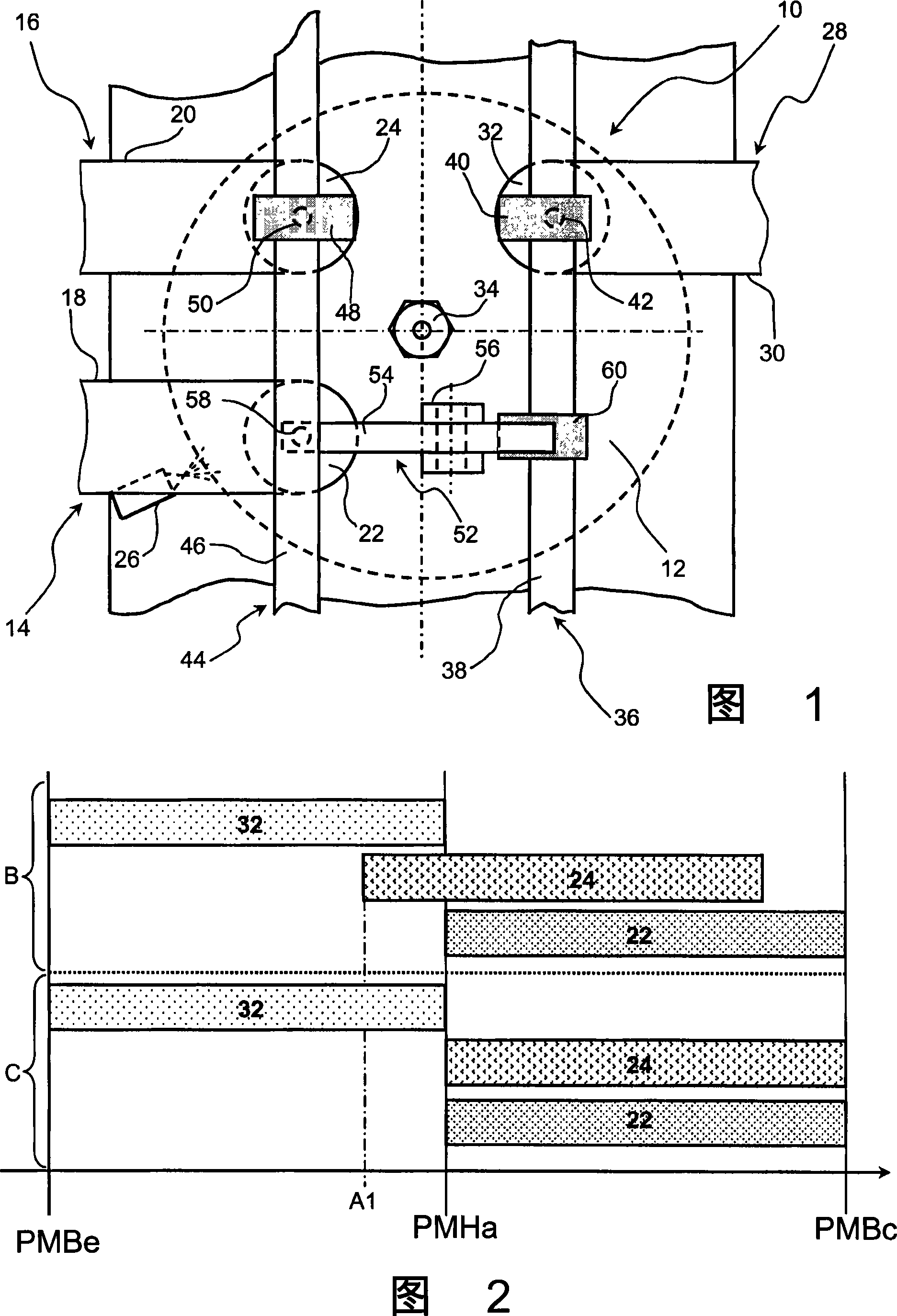

[0027] Figure 1 shows a supercharged internal combustion engine, especially of the indirect fuel injection type, more specifically a spark ignition engine.

[0028] This engine comprises at least one cylinder 10 in which a piston (not shown) reciprocates in a straight line at a first position called top dead center (PMH in the figure) and at a first position called bottom dead center (PMB). ) to another location. The cylinder comprises a combustion chamber 12 in which air or a mixture of charge air and fuel, or a mixture of charge air and fuel to which recirculated exhaust gas (EGR) has been added, is combusted.

[0029] The cylinder 10 includes a charge air (or carbonized air) intake 14 and a charge air (or air) intake 16 , the latter air being non-carbonated air in the example shown.

[0030] These air intake means generally consist of an orifice provided in the cylinder head, the engine usually being equipped with pipes 18, 20 communicating with this orifice and means 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com