Apparatus for treating substrates

A technology for processing devices and substrates, which is used in photomechanical processing of originals, patterned surface photoengraving process, optics, etc., and can solve the problems of complicated structure, long time and cost of processing liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

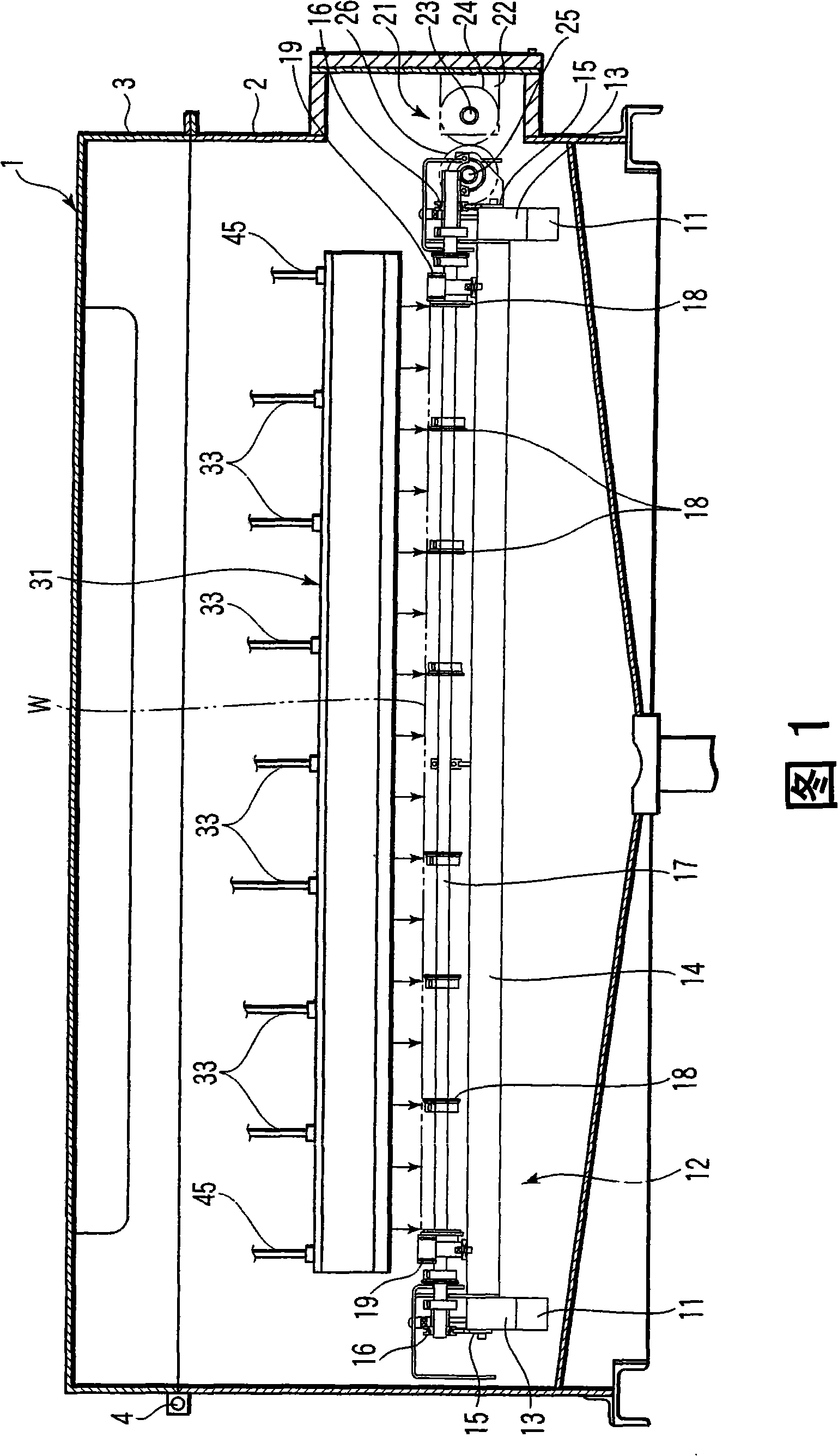

[0040] Figure 1 to Figure 4 Showing the first embodiment of the invention, figure 1 It is a longitudinal cross-sectional view along the width direction of the processing apparatus. This processing device includes a chamber 1 . The chamber 1 is composed of a main body 2 with an open upper surface and a cover 3 capable of opening and closing the upper surface opening of the main body 2 . One side in the width direction of the cover body 3 is rotatably connected to the above-mentioned main body 2 via a hinge 4 , and a handle (not shown) is provided on the other side in the width direction.

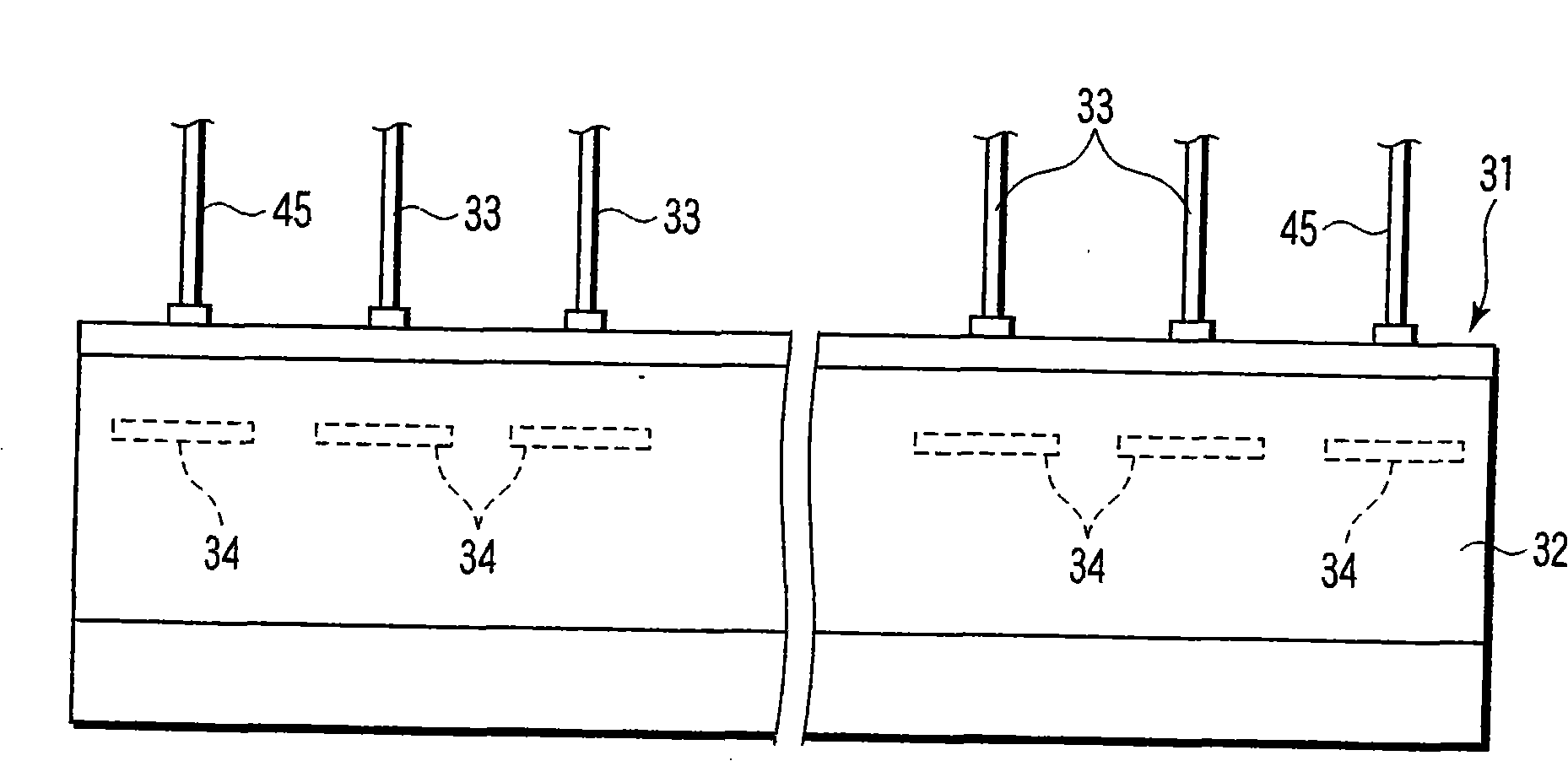

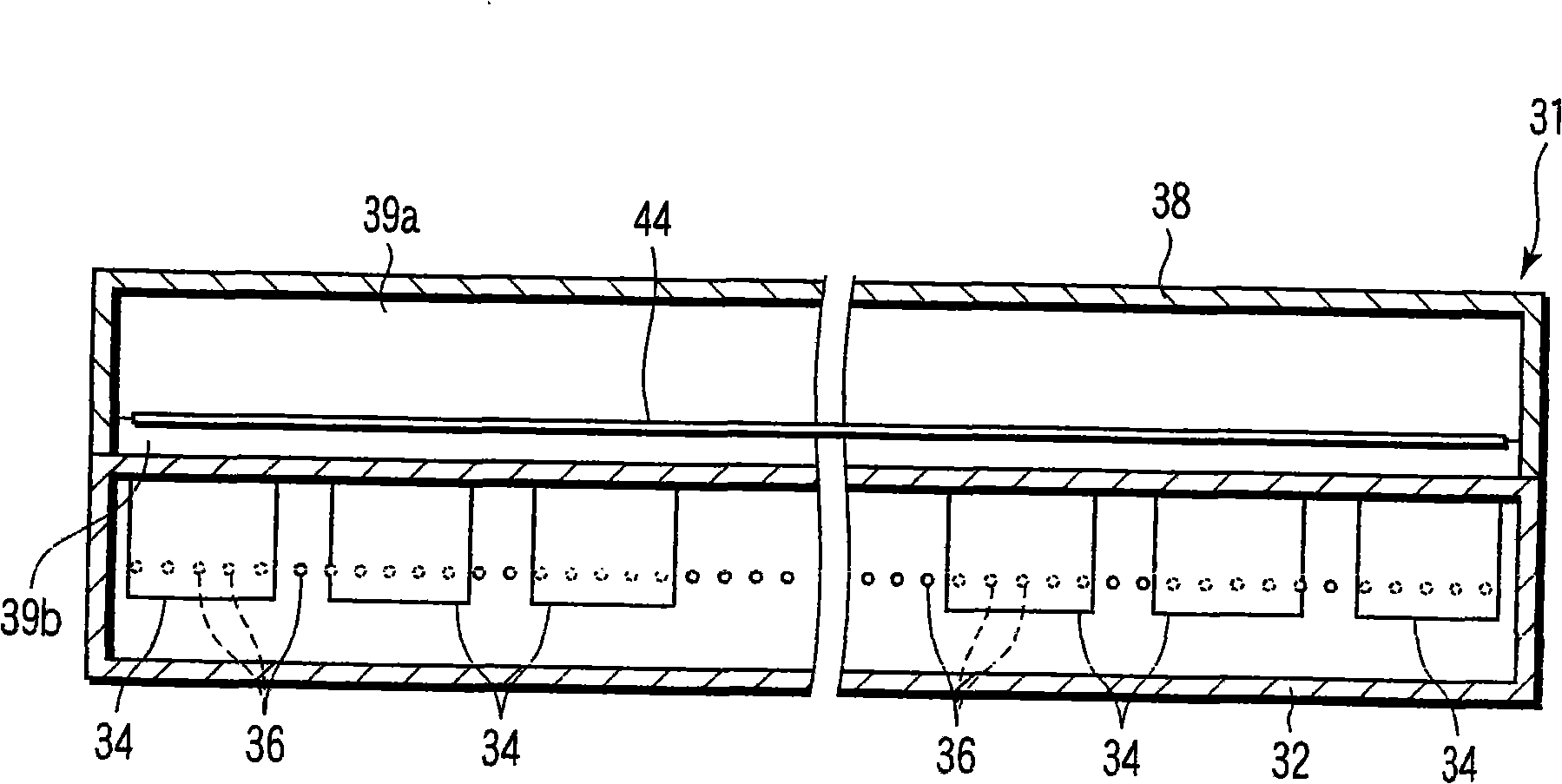

[0041] Support members 11 are provided on both ends in the width direction of the bottom of the main body portion 2 of the chamber 1 . A unitized conveyance device 12 is detachably provided on the pair of supporting members 11 . This carrier device 12 has a pair of base members 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com