Combined insulator

A technology for composite insulators and sheds, which is applied in the high-voltage field, can solve the problems of affecting the safe operation of the power grid, the short life of composite insulators, and the flashover of composite insulators. reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

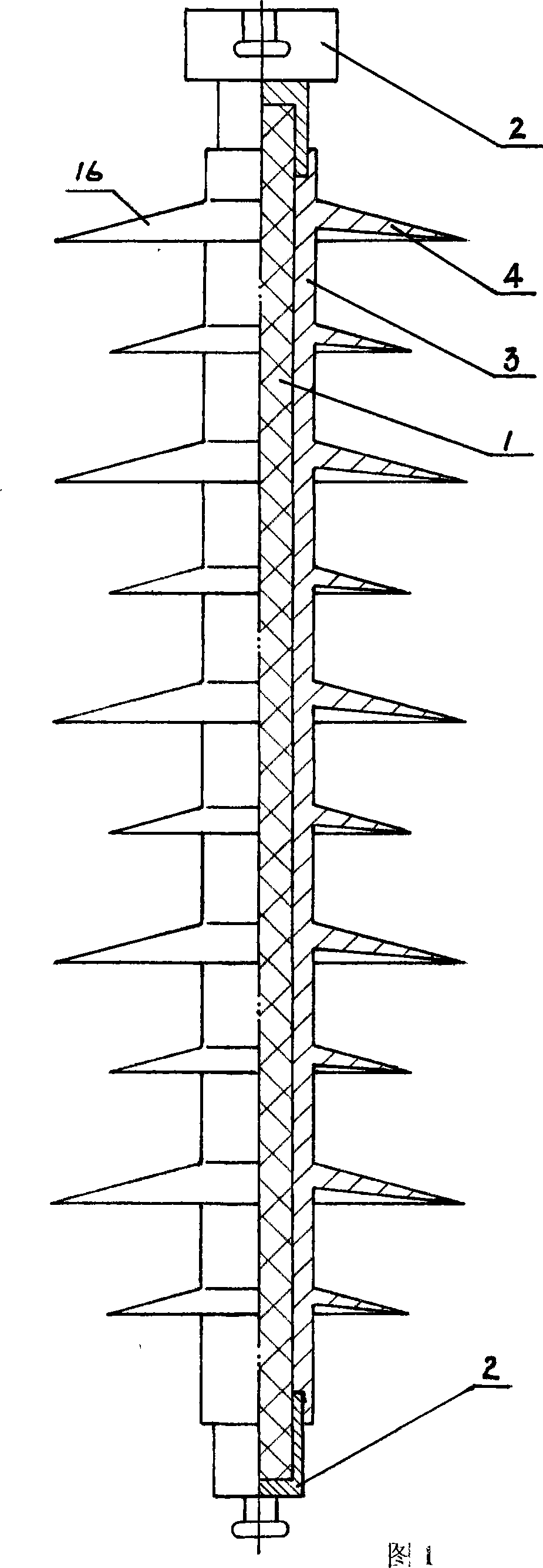

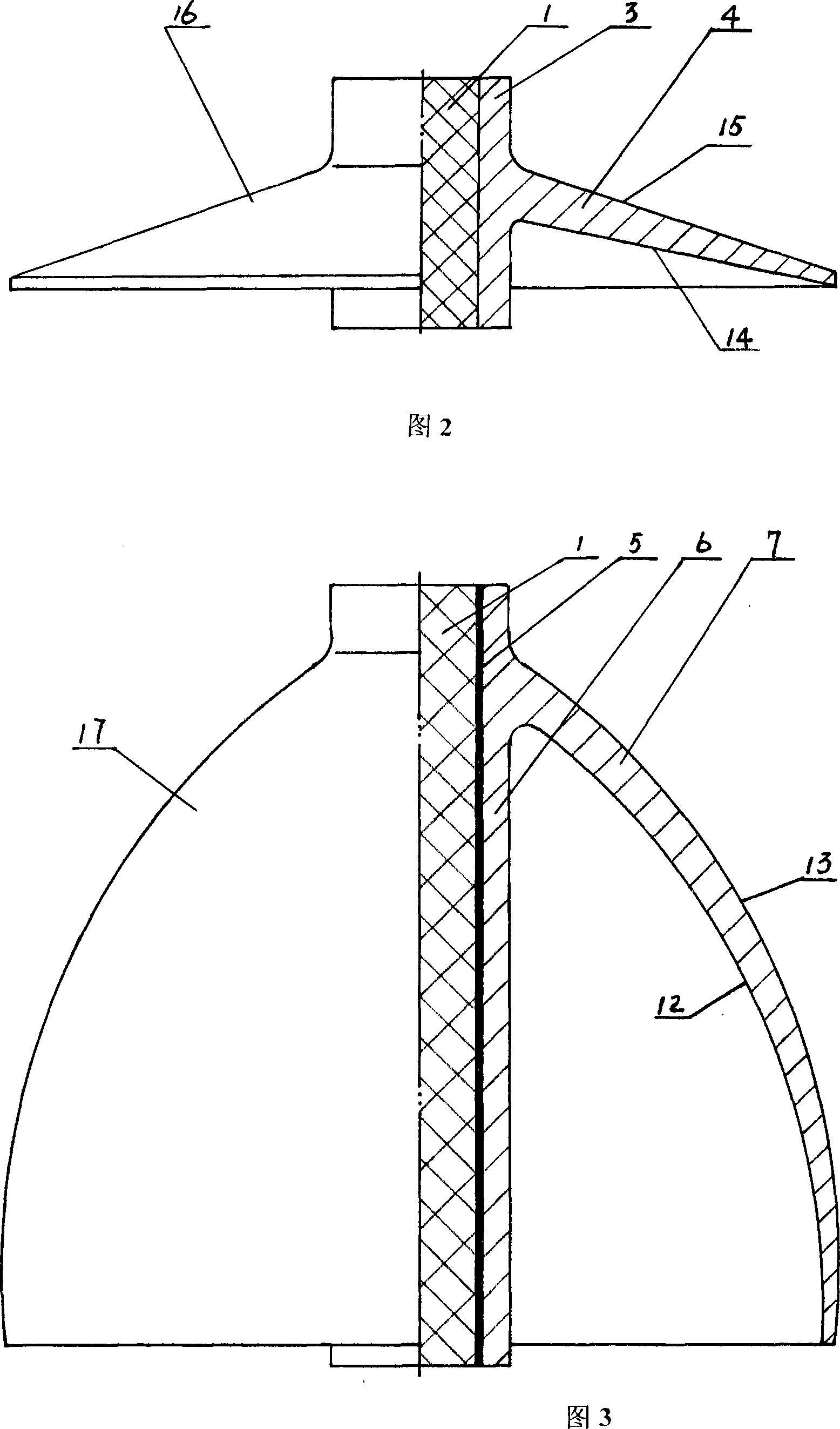

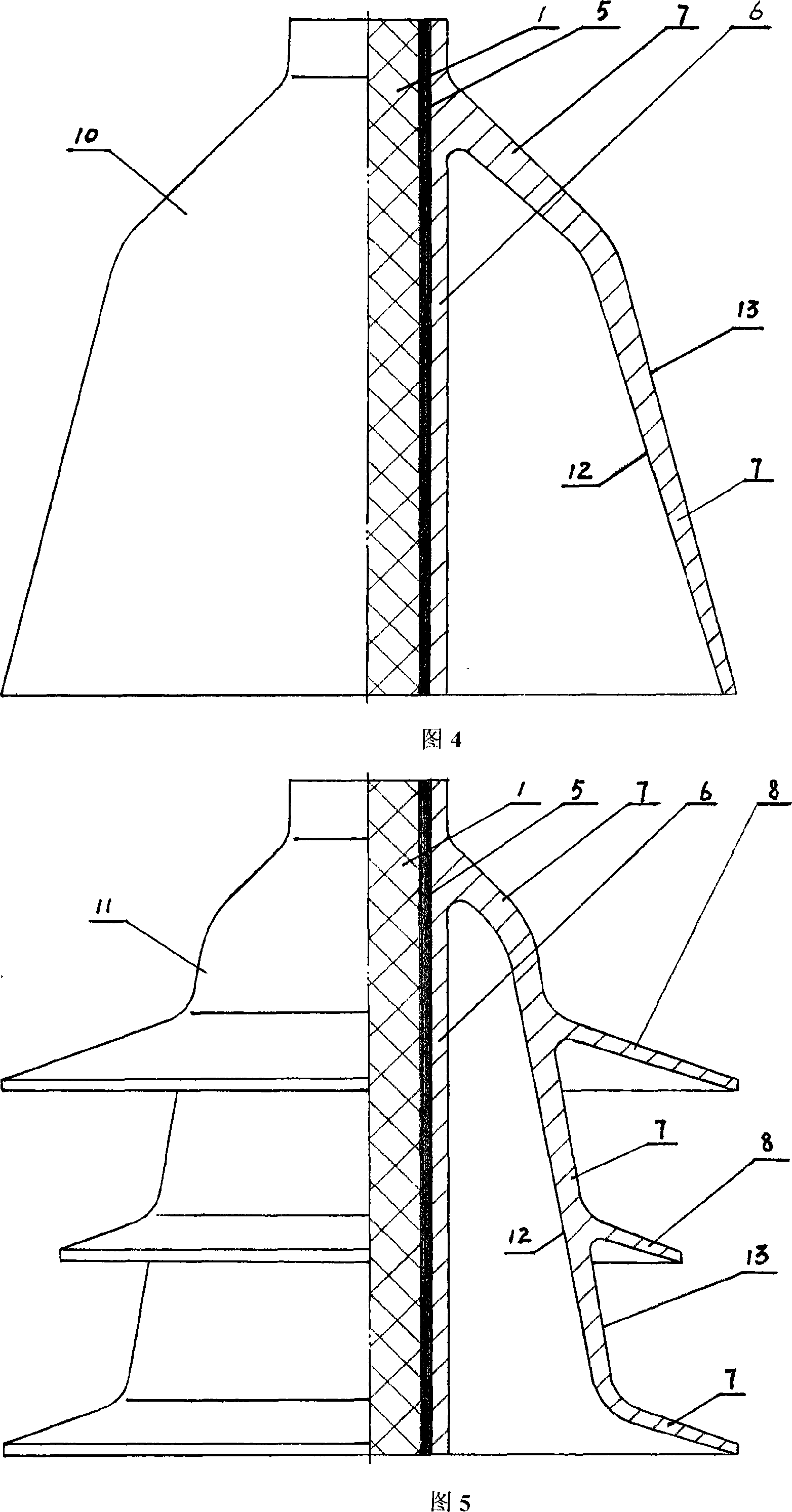

[0021] Fig. 6 is a structural schematic diagram of a composite insulator of the present invention. The upper part of the composite insulator adopts a plurality of existing sheds, and the lower part adopts two arc-shaped "bell jars" as shown in Fig. 3 Umbrella skirts are connected in series, and the center line of the axial half-section of the main shed skirt of the arc-shaped "bell-type" sheath is an arc segment, and the inclination angle of some arc segments is greater than 60°. Cavity depth greater than 45mm. A composite insulator of the present invention shown in Fig. 6 is produced in the following way: 1) use the arc-shaped "bell type" umbrella shed special mold to press and form two silicon rubber materials as shown in Fig. 3 and connect with outer sheath respectively Arc-shaped "bell-type" sheds, and cleaned and inspected; 2) Put the clean and dry mandrel into the existing integral mold for sheds and sheaths, place it on the injection vulcanizing machine, and inject it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com