Two-stage series reactor for synthesis of natural gas hydrates

A series reactor, natural gas technology, applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of hydrate ice blockage and difficulty in timely drainage of spray reactors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

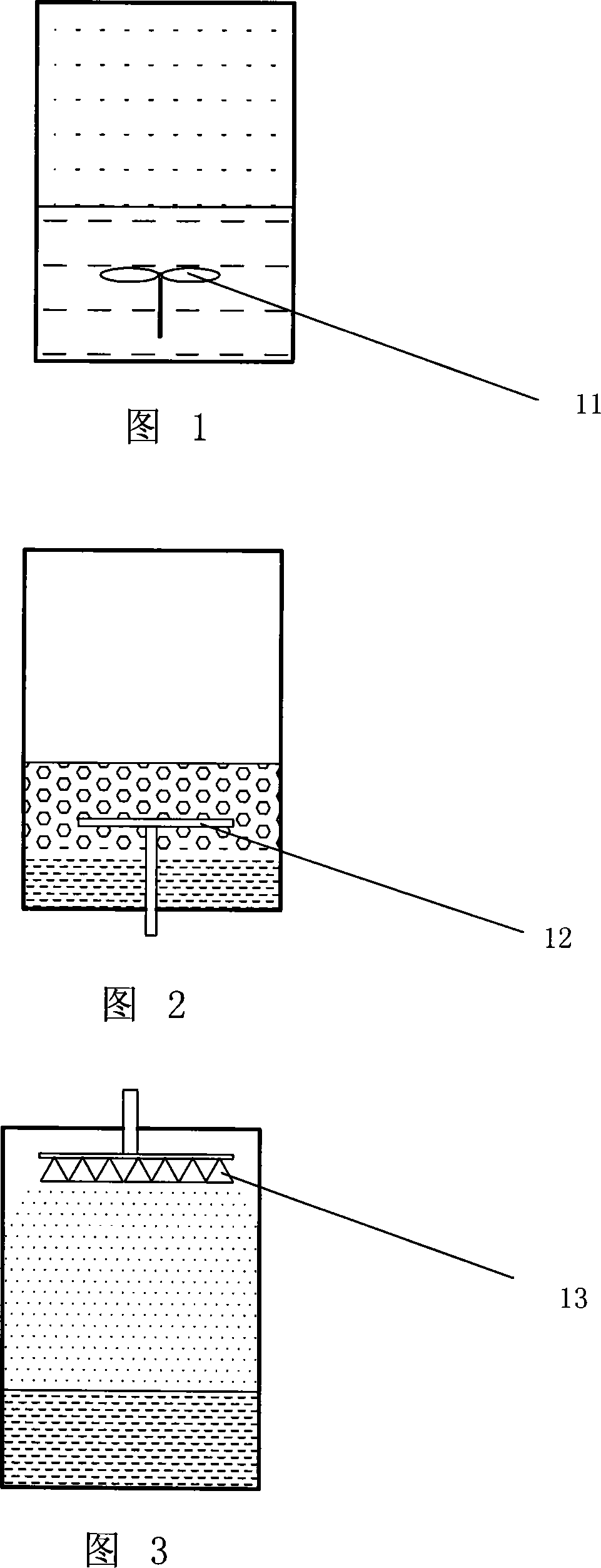

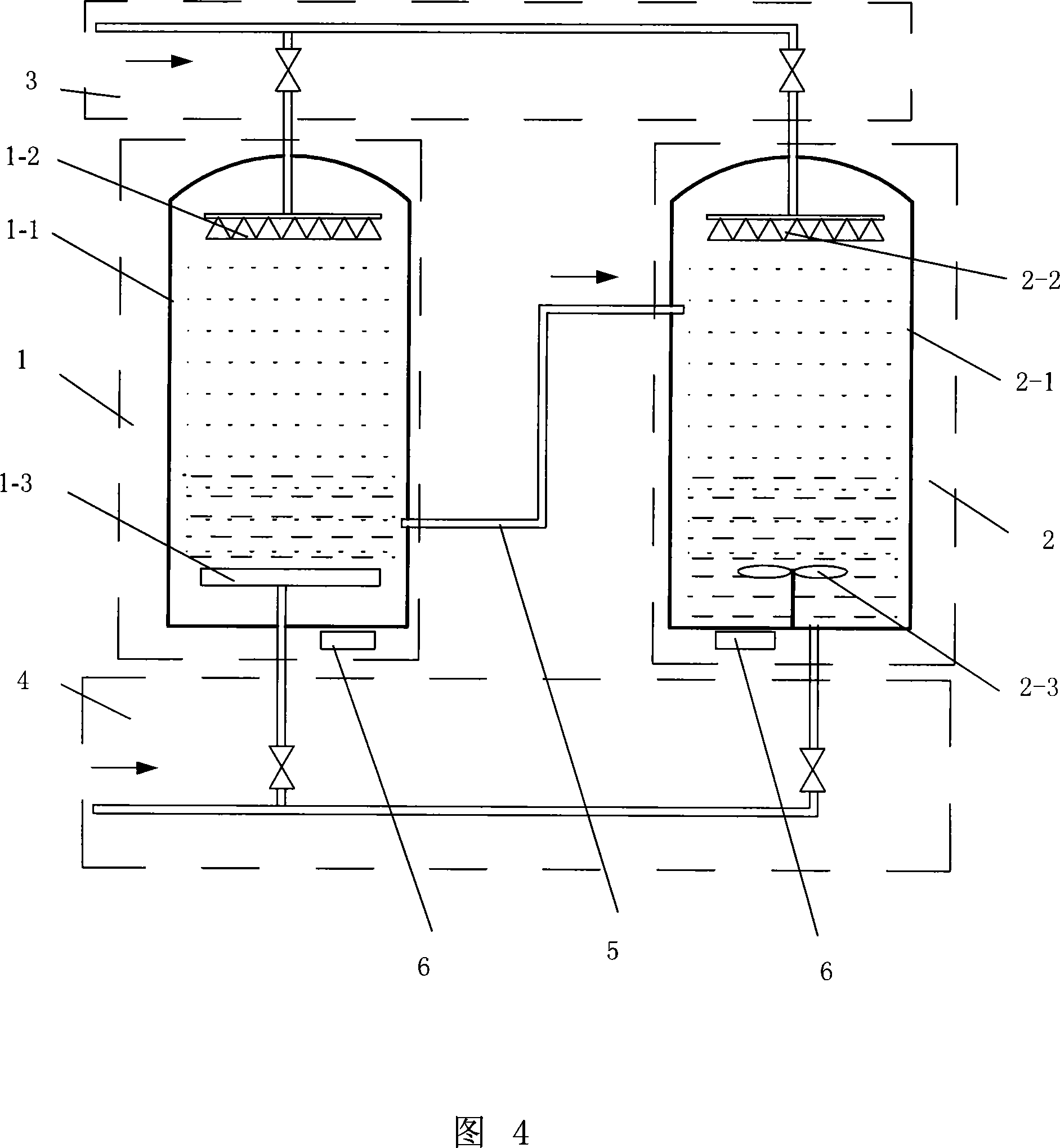

[0009] Specific Embodiment 1: The present embodiment will be specifically described below with reference to FIG. 4 . This embodiment is composed of No. 1 reactor 1, No. 2 reactor 2, water inlet pipe 3, natural gas inlet pipe 4 and delivery pipeline 5. No. 1 reactor 1 is composed of No. 1 kettle body 1-1 and No. 1 spraying device. 1-2 and orifice device 1-3, the No. 2 reactor 2 is composed of the No. 2 kettle body 2-1, the No. It is arranged on the upper top of the inner cavity of the No. 1 kettle body 1-1 and communicates with the water inlet pipe 3. The orifice device 1-3 is arranged at the bottom of the inner cavity of the No. 1 kettle body 1-1 and communicated with the natural gas inlet pipe 4. The No. 2 spraying device 2-2 is arranged on the upper top of the No. 2 still body 2-1 inner cavity and communicates with the water inlet pipe 3, and the stirring device 2-3 is arranged on the bottom of the No. 2 still body 2-1 inner cavity. The bottom of the No. 2 kettle body 2-1 i...

specific Embodiment approach 2

[0010] Specific Embodiment 2: The present embodiment will be specifically described below with reference to FIG. 4 . The difference between this embodiment and Embodiment 1 is that ultrasonic generators 6 are provided at the bottom of No. 1 kettle body 1-1 and the bottom of No. 2 kettle body 2-1. The action of ultrasonic waves can increase the gas storage density of hydrates and accelerate the synthesis speed of hydrates.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com