Heating high temperature valve and uses thereof

A valve and high-temperature technology, which is applied in the field of heating high-temperature valves, can solve problems such as air leakage, electric heating wire out of the groove, and tight closure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

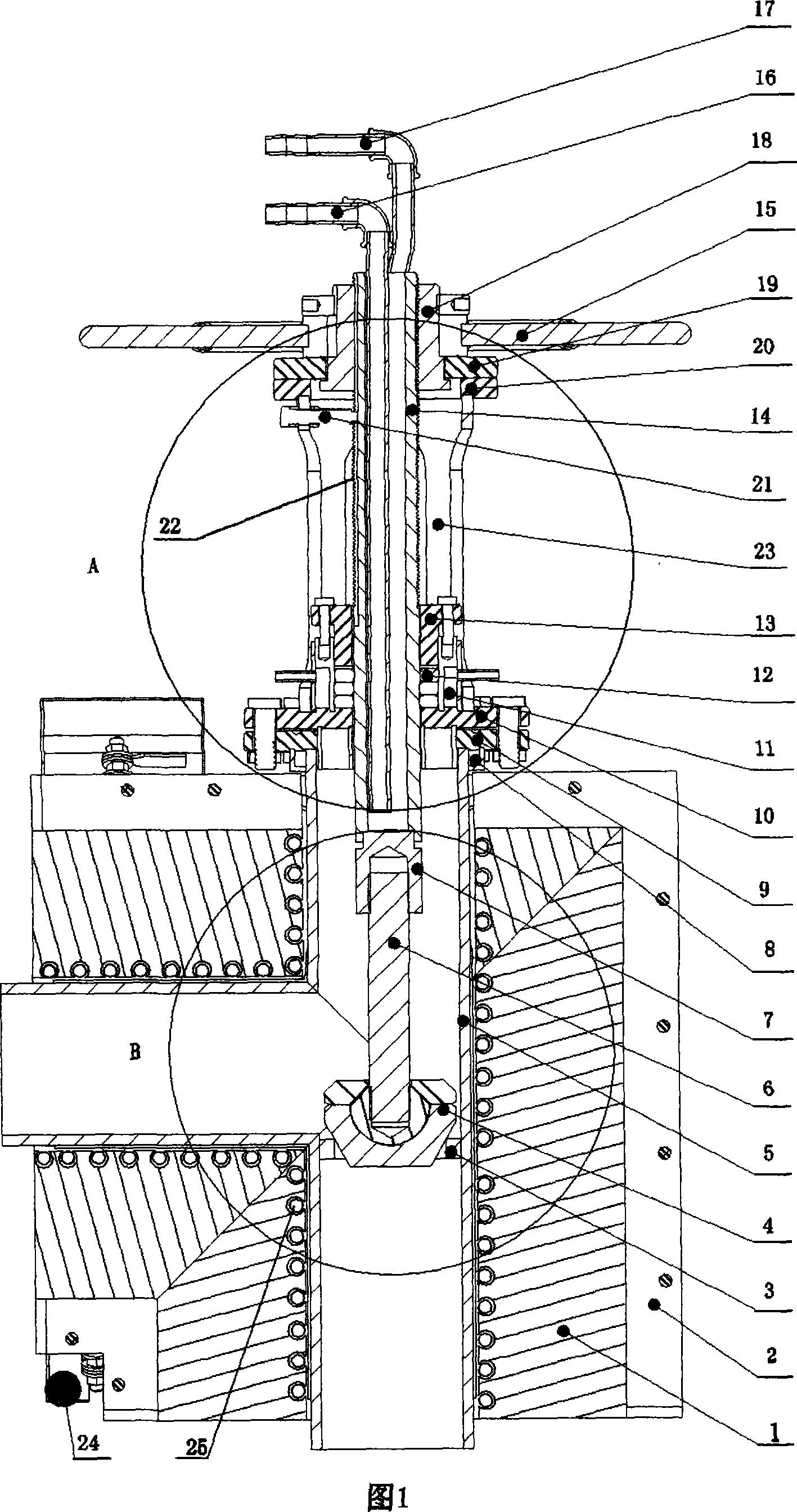

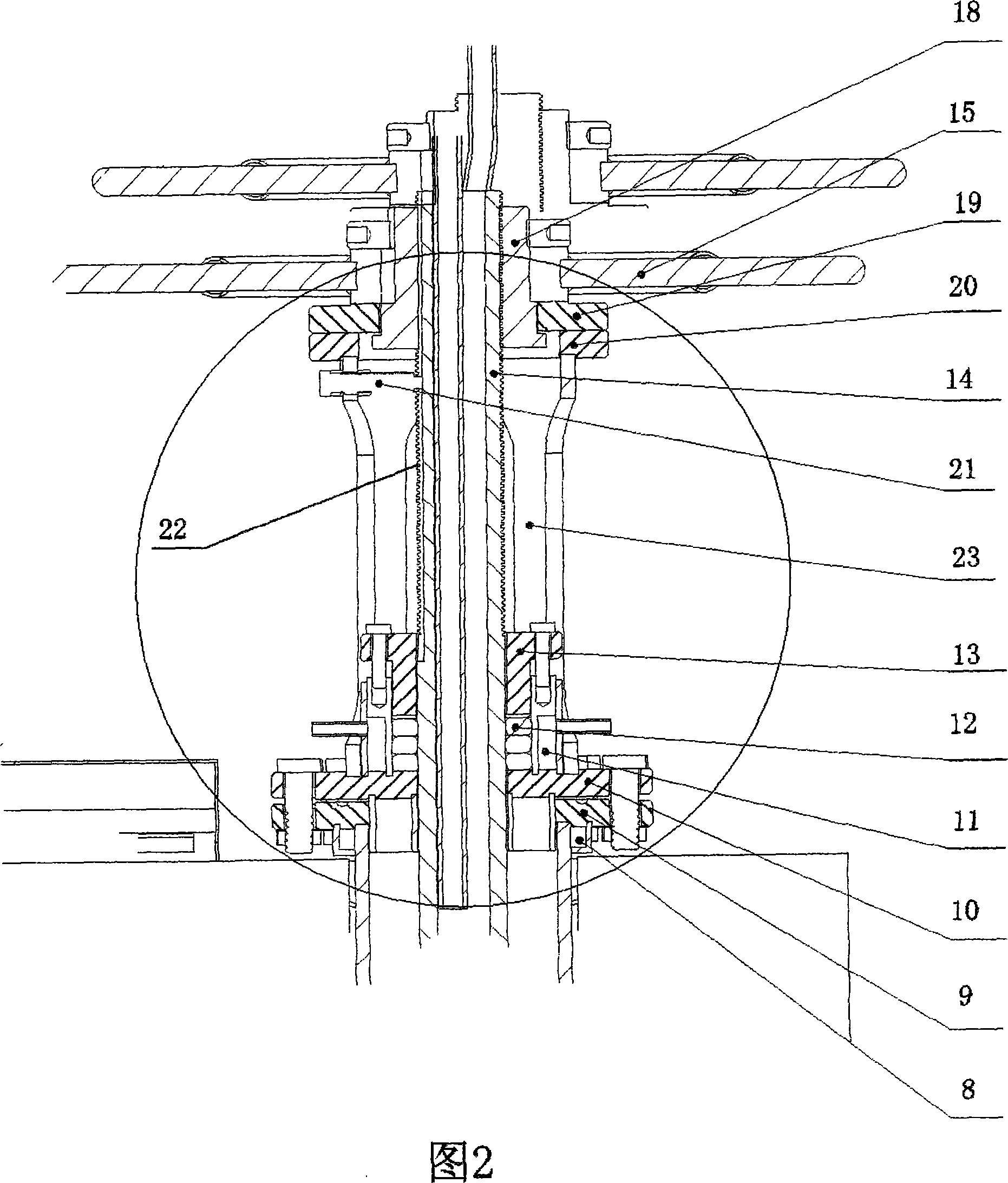

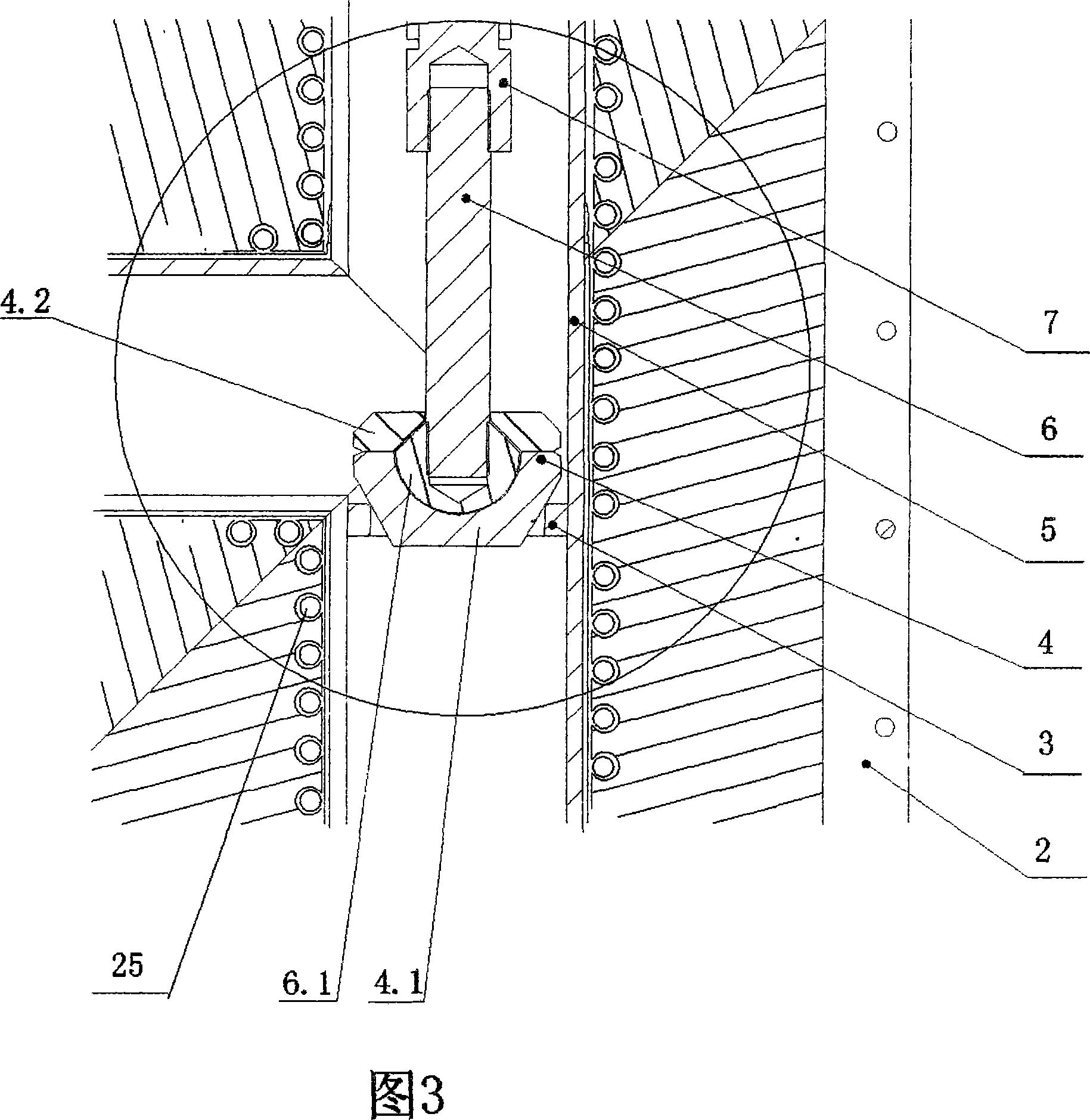

[0008] A heating high-temperature valve, which is installed with a ring valve seat 3 in the valve body 5 of the three-way structure, and a valve body flange 9 with a cooling water jacket 8 is installed on the upper end of the valve body 5, and the valve stem 6 and the transmission mechanism are both Installed on the bracket flange, and then connected to the valve body flange 9 through the lower flange 10 of the bracket flange, a sealing ring 12 and a cooling water jacket 11 are arranged in the flange of the lower flange 10 of the bracket flange, and the sealing ring Compression ring 13 is arranged on the top of 12. The so-called bracket flange is formed by connecting the upper flange 20 and the lower flange 10 by the bracket 23 . A water-cooled lead screw 14 is installed in the bracket flange, and the water-cooled lead screw 14 is connected to the valve stem 6 through the valve stem joint 7, and the lower end of the valve stem 6 is threaded to the valve stem head 6.1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com