Coordination hydride catalyzed reversible hydrogen storage materials and method of preparing the same

A technology of coordination hydride and hydrogen storage material, applied in the field of coordination hydride catalyzed reversible hydrogen storage material and its preparation, can solve the problems of slow hydrogen absorption and desorption kinetics and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

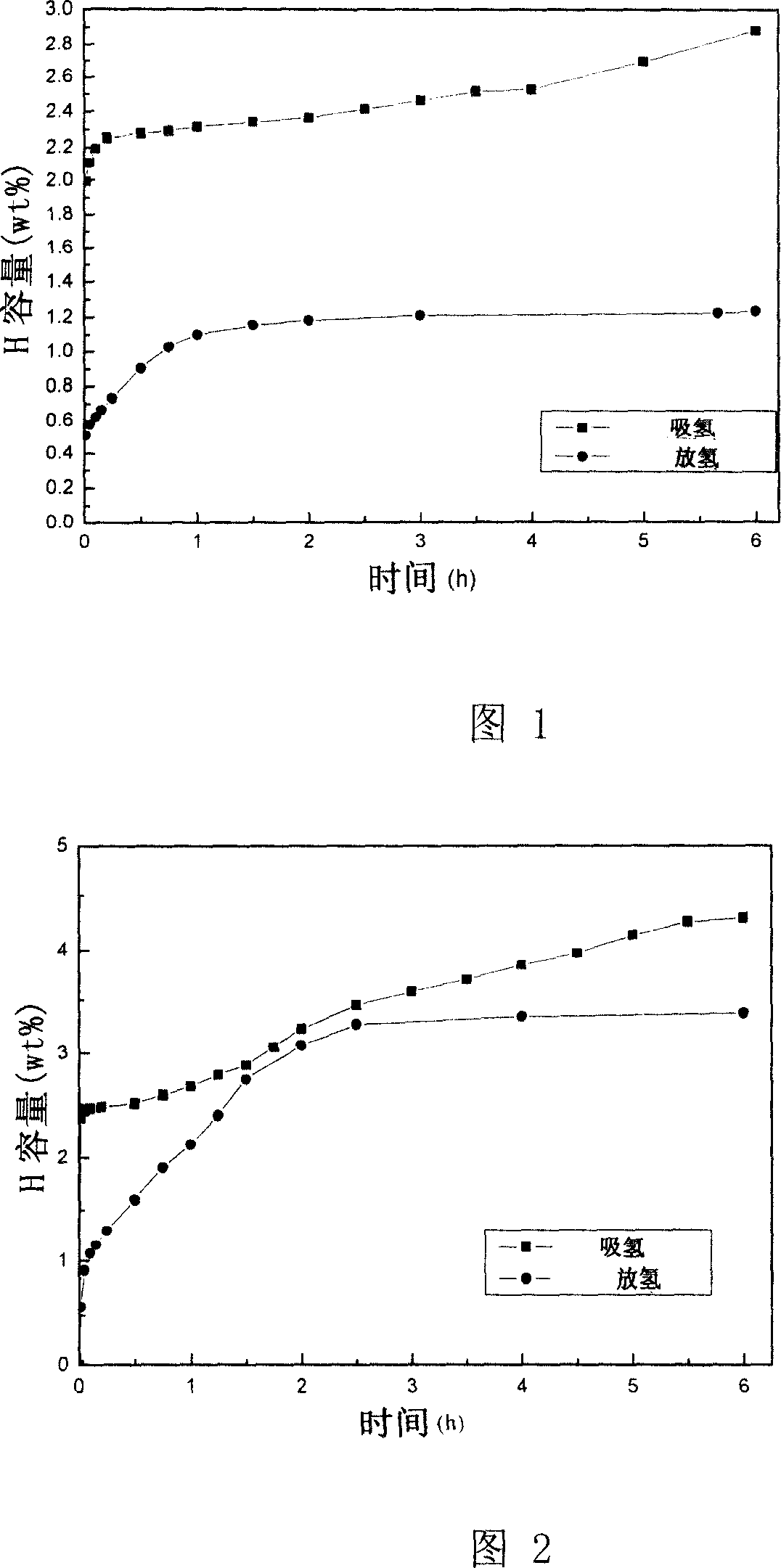

[0036] NaAlH was prepared by high-energy ball milling (weight ratio of ball to material 4 / 1, hydrogen pressure 3MPa). 4 Add 1mol% Ti(OC 4 h 9 ) 4 The hydrogen absorption and desorption kinetic curve at 150°C of the material ball milled for 4 hours is shown in Figure 1. The hydrogen absorption and desorption amount of the material reached 2.9wt% within 6 hours, and the hydrogen desorption amount was only 1.2wt%.

Embodiment 2

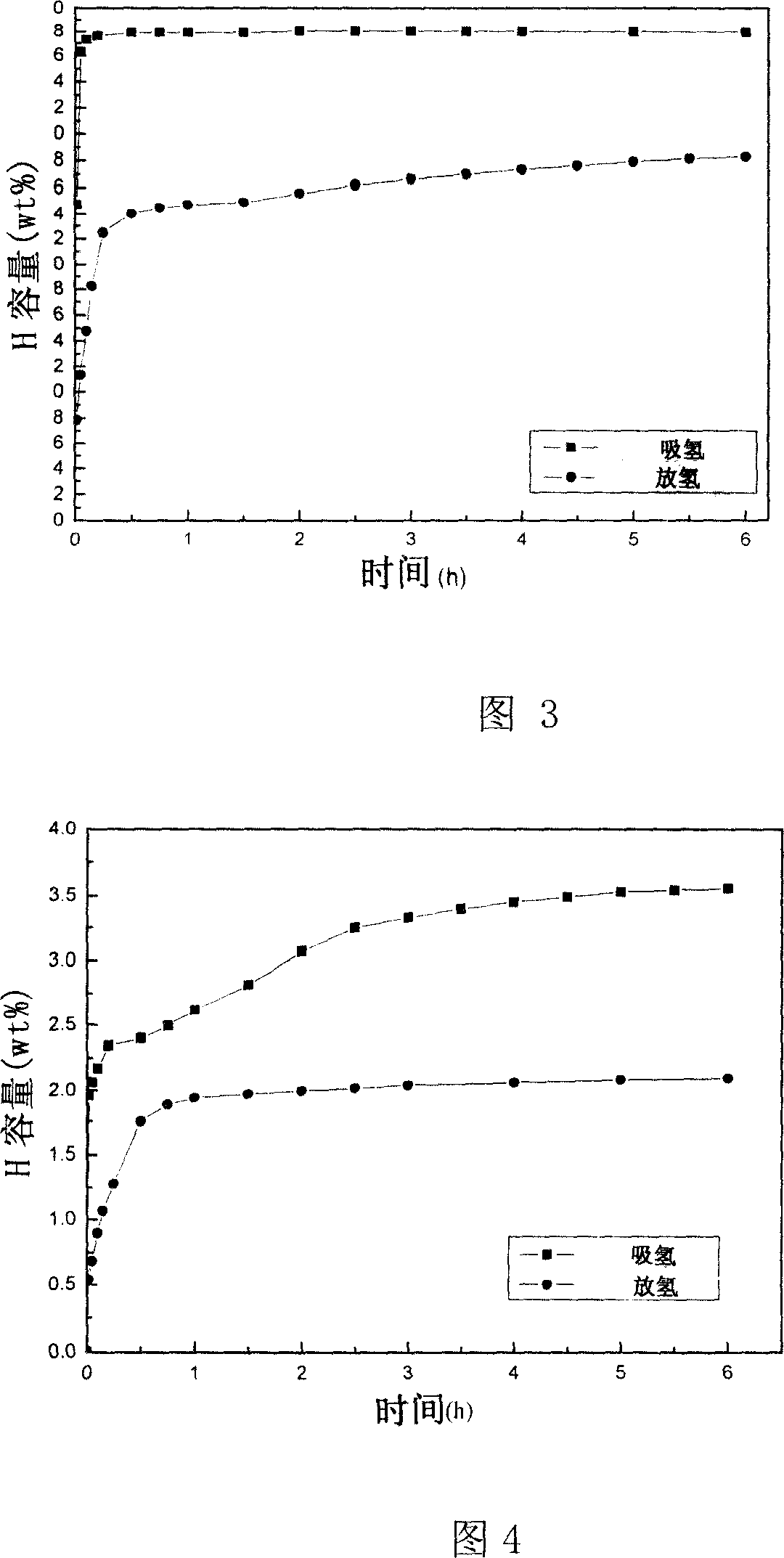

[0038] NaAlH was prepared by high-energy ball milling (weight ratio of ball to material 10 / 1, hydrogen pressure 3MPa). 4 Add 2mol%Ti(OC 4 h 9 ) 4 The hydrogen absorption and desorption kinetic curve at 150°C of the material ball milled for 4 hours is shown in Figure 2. The hydrogen absorption and desorption amount of the material can reach 4.3wt% and 3.4wt% within 6 hours.

Embodiment 3

[0040] NaAlH was prepared by high-energy ball milling (weight ratio of ball to material 20 / 1, hydrogen pressure 3MPa). 4 Add 6mol% Ti(OC 4 h 9 ) 4 The hydrogen absorption and desorption kinetic curve at 150°C of the material ball milled for 4 hours is shown in Figure 3. The hydrogen absorption and desorption amount of the material reached 3.8wt% and the hydrogen desorption amount reached 2.7wt% within 6 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com