Composite purification device for continuously removing zinc slag in heat zinc coating liquid

A composite purification, hot-dip galvanizing technology, applied in hot-dip plating process, process efficiency improvement, coating and other directions, can solve the problems of increasing the cost of hot-dip galvanizing, insufficient purification efficiency and effect of zinc pot, waste of resources, etc. The effect of reducing slag defects, reducing zinc consumption, and reducing zinc slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

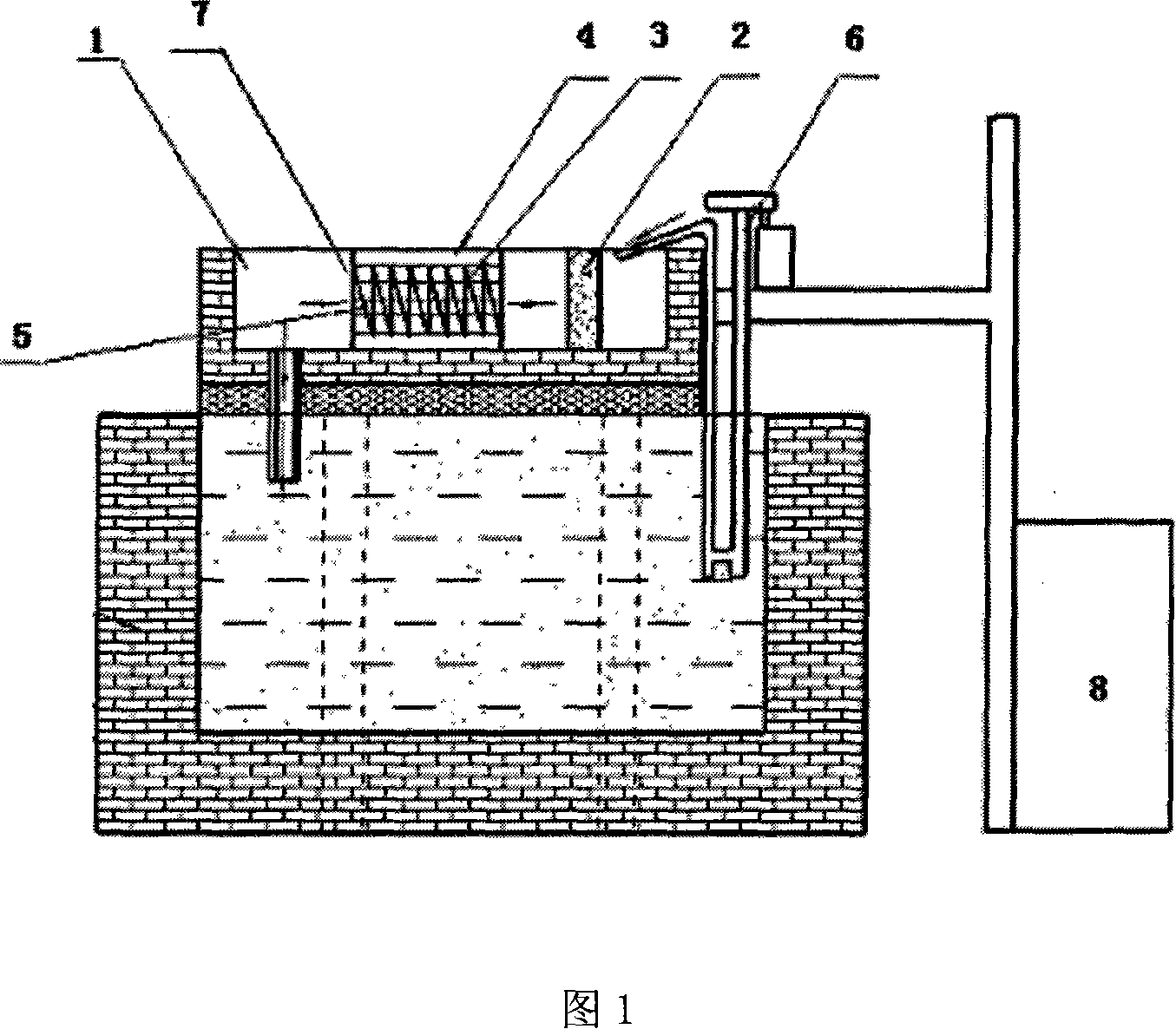

[0012] The embodiments of the present invention are described in detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and processes are provided, but the protection scope of the present invention is not limited to the following implementations example.

[0013] As shown in Fig. 1, this embodiment includes: a liquid zinc conveying device, a primary filter and a secondary electromagnetic slag removal device. The liquid zinc conveying device includes a liquid zinc pump 6 and a liquid zinc launder 1 . The primary filter is a ceramic foam filter 2. The secondary electromagnetic slag removal device includes an induction coil 3 , a heat insulation sleeve 4 , a porous ceramic tube 5 and a refractory shell 7 . The zinc liquid pump 6 is placed above the zinc pot, the zinc pump 6 pumps the zinc pipe and is immersed in the zinc pot, the foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com