Press die casting device and press die casting method

A pressurized casting and pressure-increasing technology, which is applied in the field of pressurized casting, can solve the problems of increasing pressurized pressure and inability to obtain quality casting products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

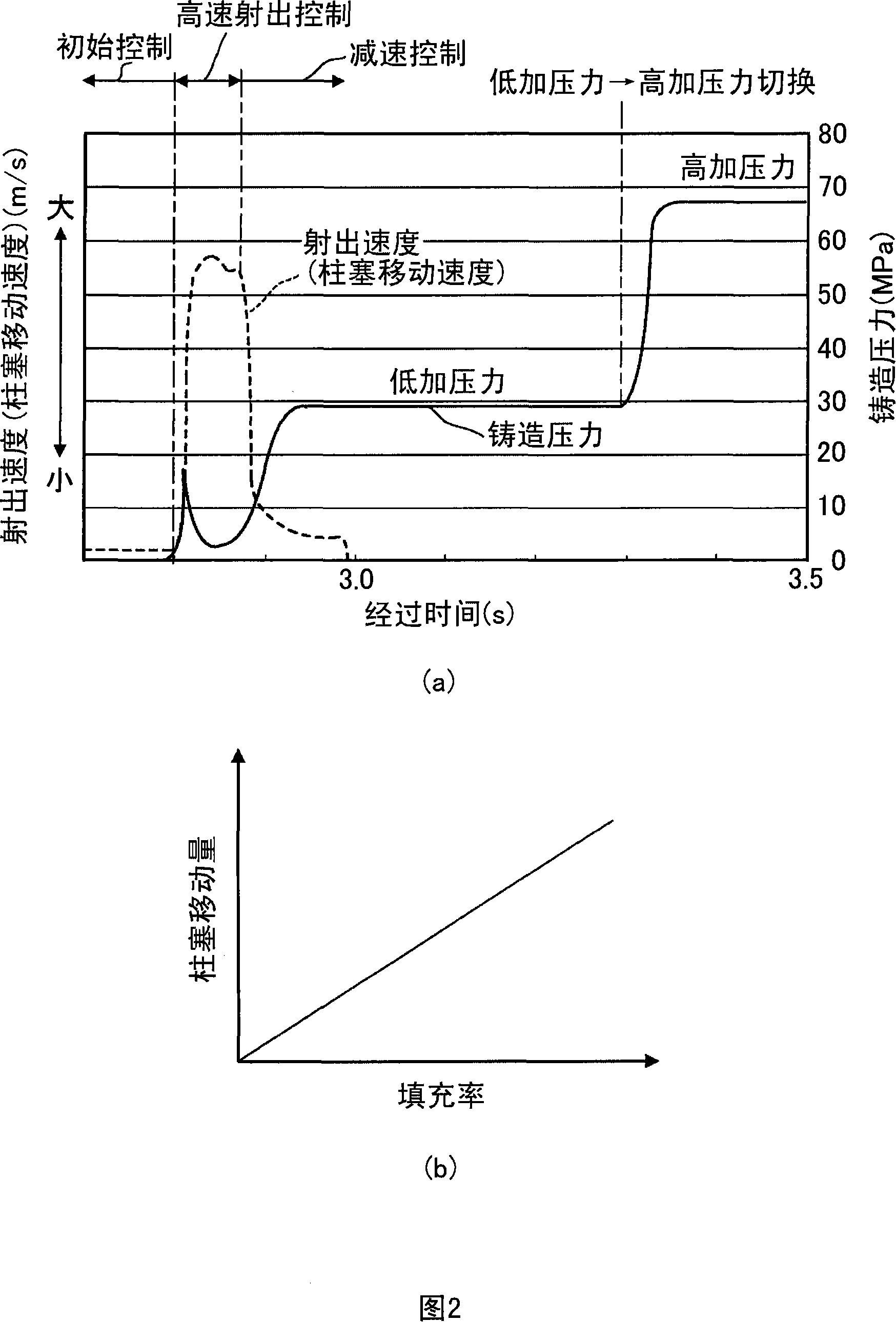

[0059] Casting roughness was investigated in the case of changing the filling rate at the timing of switching from high-speed injection control to deceleration control, and increasing the pressure after filling the melt in one step and in two steps. The amount of mouth and the incidence of trachoma. The casting object is the cylinder block of the engine, and the melt is aluminum alloy melt. The pressurization pressure after filling the molten metal is about 70MPa in one stage, about 30MPa in the first stage and about 70MPa in the second stage in two stages. When the pressurization pressure after filling the melt is increased in two stages, the timing of switching the pressurization pressure is 0.45 seconds after the measurement from the time when the fill rate of the melt reaches 92%.

[0060] Fig. 4 is a schematic diagram showing experimental results. Fig. 4(a) shows the relationship between the amount of casting burrs and the filling rate as the timing for switching from hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com