Laser cladding working head adapted for cladding layer capability gradient change

A gradient change and laser cladding technology, which is applied in laser welding equipment, metal material coating process, coating, etc., can solve the continuous change of continuous change and the continuous change of cladding layer performance. Incompatibility and other problems, to achieve the effect of reducing the outflow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

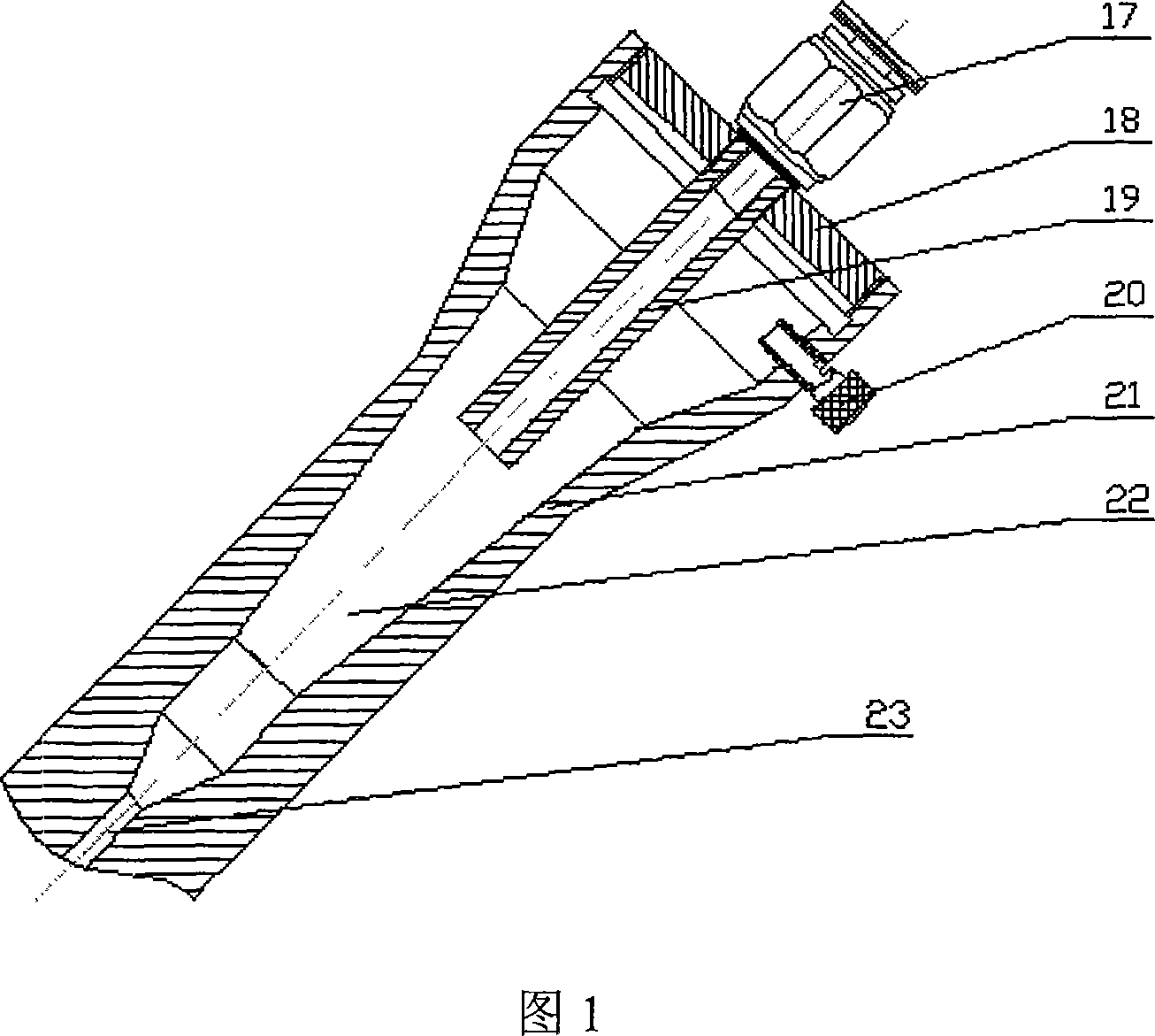

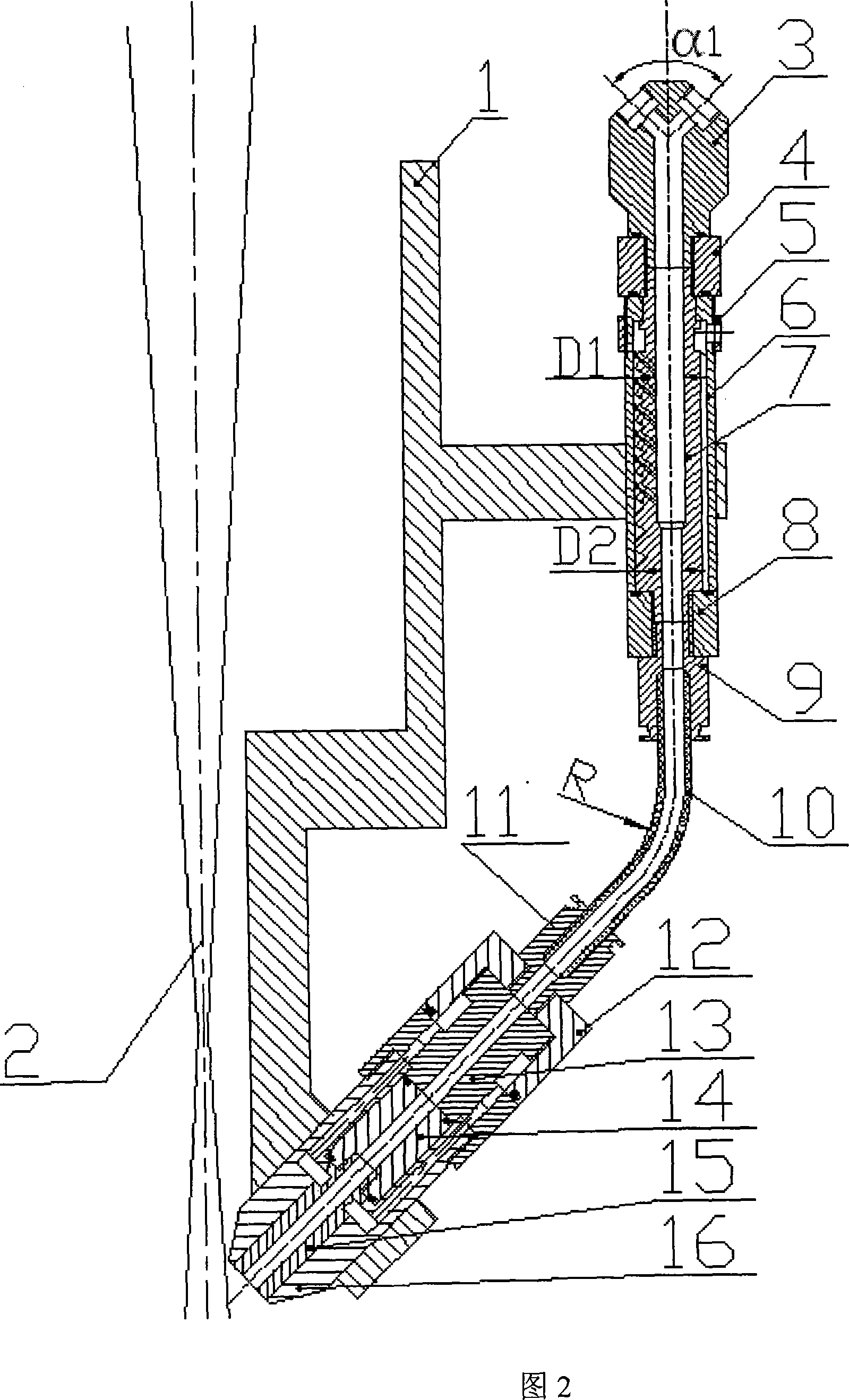

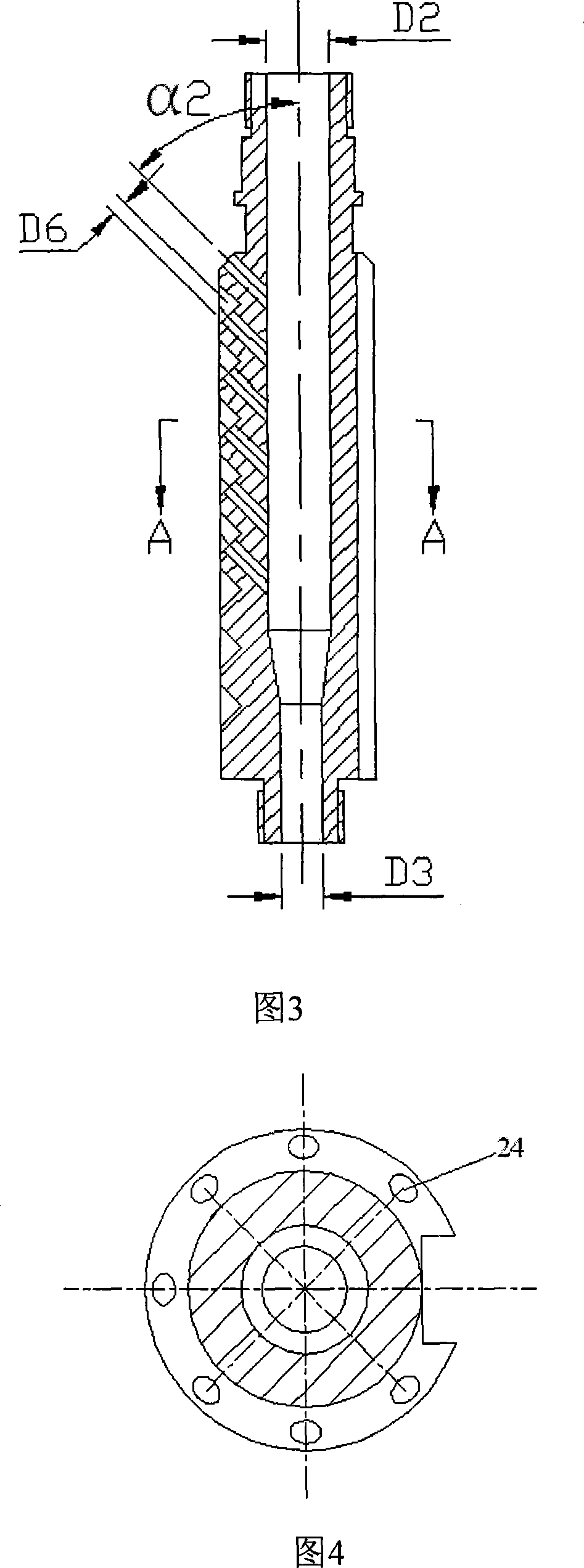

[0018] The present invention is a laser cladding working head suitable for the gradient change of cladding layer performance. It consists of two parts: powder gas separation and powder conveying. It is processed and assembled according to the design of Fig. 2 to Fig. 3. The powder conveying part includes the upper connecting head 9, Powder conveying connecting pipe 10, lower connecting head 11, sealing cap 12, protective gas input cylinder 13, powder feeding nozzle pressure cap 14, powder feeding nozzle 15, powder feeding nozzle seat 16, wherein: powder feeding nozzle 15 passes through the upper screw thread The powder feeding nozzle pressure cap 14 is connected together, the powder feeding nozzle 15 and the powder feeding nozzle pressure cap 14 are installed in the powder feeding nozzle seat body 16, the protective gas input cylinder 13 is threaded on the upper part of the powder feeding nozzle body 16, and the cap is sealed 12 is threaded on the upper part of the protective g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com