High purity instant protein powder producing method

A technology of protein powder and production method, which is applied in the direction of plant protein processing and texturization to achieve the effects of high nutritional value, mellow taste and ash reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

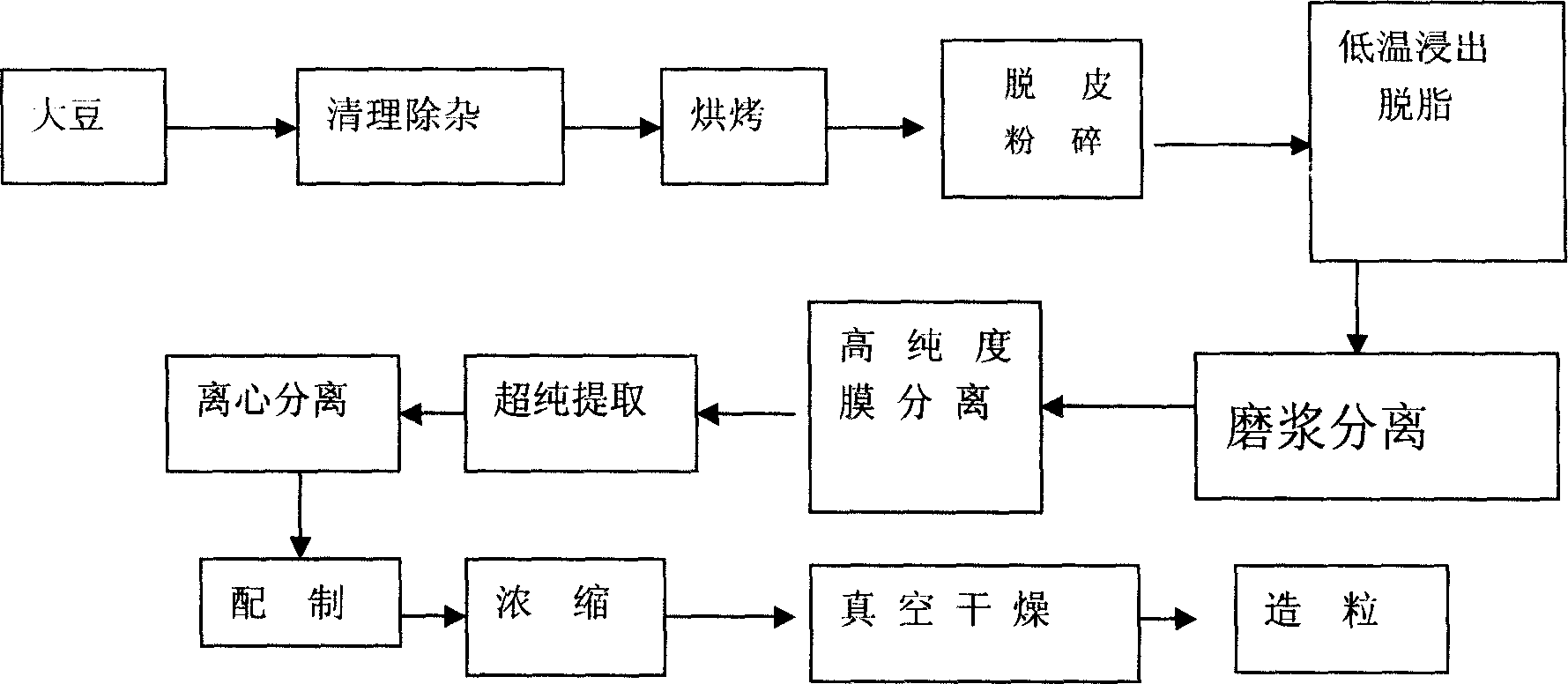

Method used

Image

Examples

Embodiment approach

[0018] First of all, select soybeans, that is, select fresh, bright color, uniform and intact particles, less impurities, and no mold spots. At the same time, soybeans should be screened and cleaned by dry cleaning. Vibration screening and vacuum transportation are used for separation and cleaning. . Then dry it by dry method until the water content is 8%, then it can be crushed and peeled, so that the husk content of the crushed soybeans is less than 8%, and finally crushed and classified by a hammer mill, so that the product particles can be kept at 0.2mm-0.5mm , The requirement of this process is not to use strong heat treatment, the drying temperature should not exceed 80 ℃, avoid direct steam heating so as to ensure the solubility of the product, and the protein retention rate is above 95%.

[0019] The degreasing method is degreasing by extracting meal with low denaturation. The protein denaturation degree of the extracting meal obtained by this method is low, and high-q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com