Industrial production method of corn protein polypeptide from corn protein powder by enzymatical process

A corn gluten meal, corn gluten technology, applied in fermentation and other directions, can solve the problems of difficult control of the reaction process and the final product, amino acid damage, difficult to filter and other problems, and achieve the effect of improving scientific and technological content and quality, small molecular weight, and easy filtration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

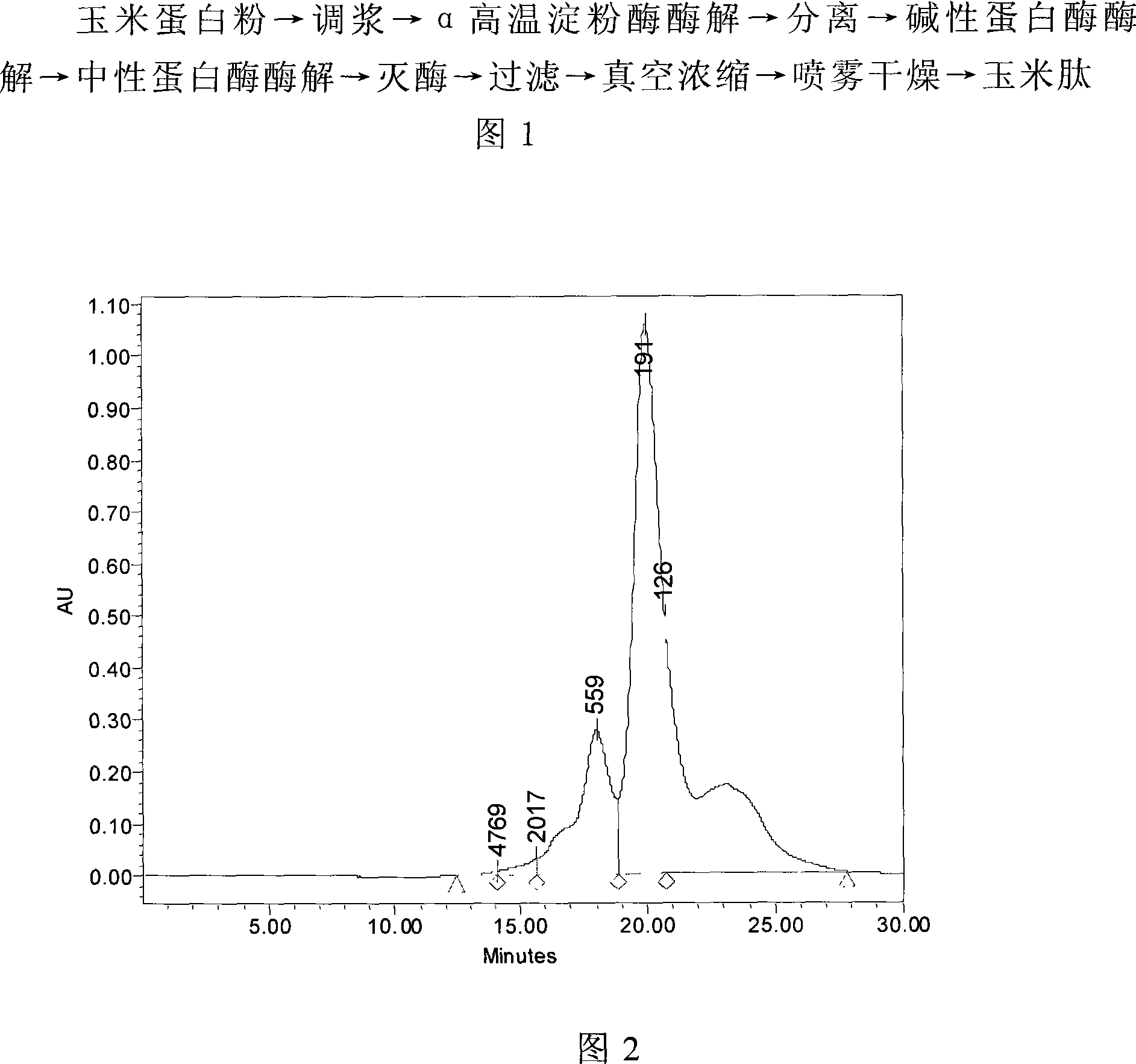

[0023] Accompanying drawing is a kind of specific embodiment of the present invention. As shown in Figure 1, this embodiment includes the following steps:

[0024] 1. Raw material requirements

[0025] ③ Corn Gluten Powder: Moisture ≤6.0%, Protein ≥64%, Ash ≤2.0%

[0026] ④Ion-free water: PH7.5-10 conductivity≤50us / cm

[0027] ⑤Enzyme preparation: α high temperature amylase 20000u / g alkaline protease 360000u / g

[0028] Neutral protease 130000u / g

[0029] 2. Put in 1kg of corn gluten powder, add 11500-7500ml of deionized water (sizing concentration 8-12%) after feeding, heat at 95-98°C and soak for 1 hour, and cut through the emulsifying shear at the bottom of the tank. and flow back into the tank.

[0030] 3. Add 15-20ml of 30% calcium hydroxide to adjust the pH of the feed solution to 6.5-7.0 and heat to 95-98°C, add 6.25-8.0ml of 0.625-0.8% α high-temperature amylase, and start enzymatic hydrolysis. 0.5 hours pH6.0-6.4 plus 30% calcium hydroxide 8-15ml pH6.5-7.0, 1.5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com