Automatic plate moving mechanism of large-diameter high-accuracy glass polishing machine

A high-precision, polishing machine technology, used in grinding machine parts, grinding/polishing equipment, and machine tools suitable for grinding workpiece planes, etc., can solve problems such as cumbersome operation procedures, downtime, etc. The effect of reducing workplace injuries, reducing procedures and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

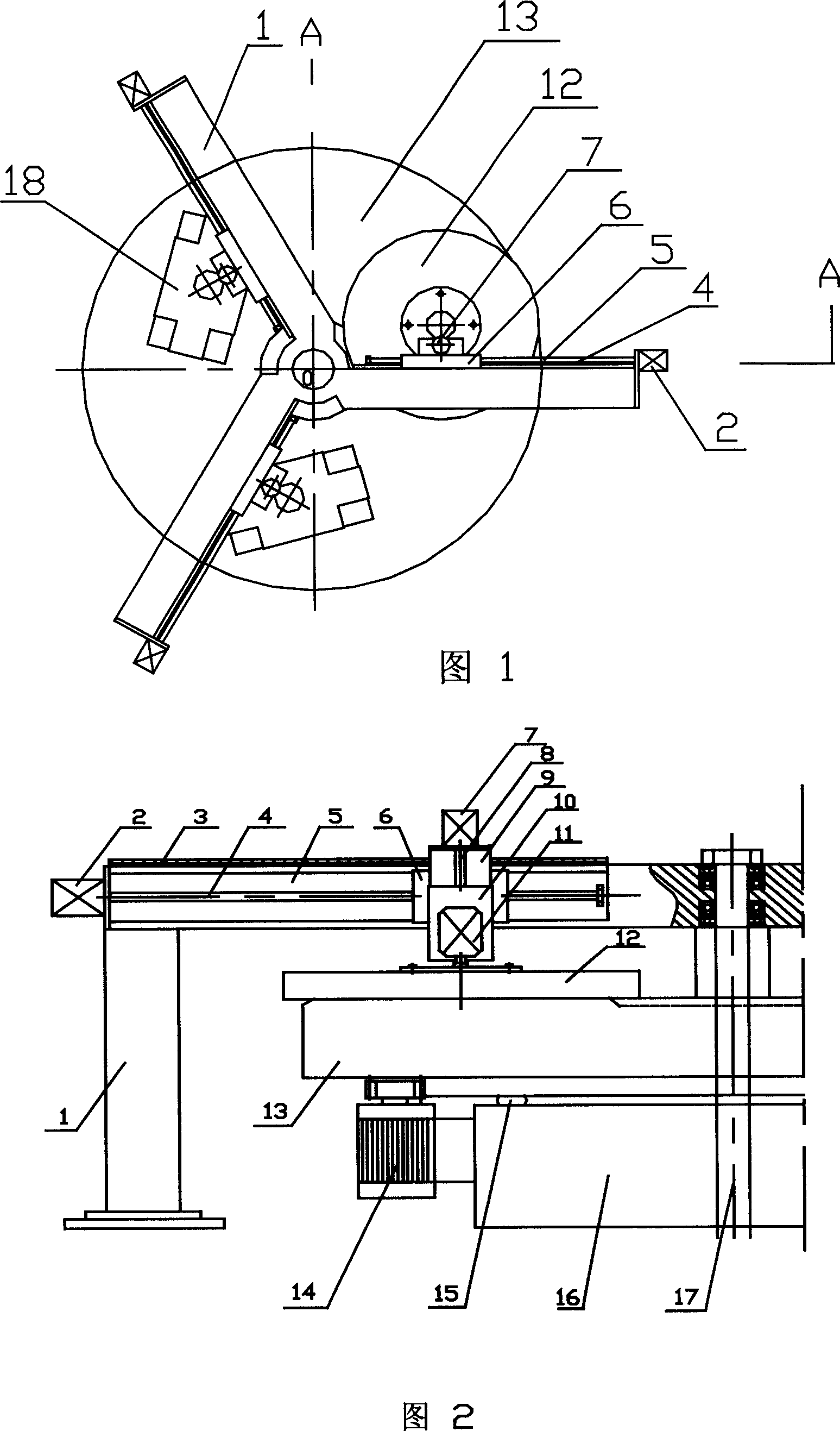

[0017] An embodiment of the present invention is shown in Fig. 1 and Fig. 2 . It mainly includes a large turntable 13 pivotally arranged on the base 16, the upper layer of the large turntable is provided with a plastic plate with abrasives, and a trimming plate 12 and two workpiece plates 18 are placed on the rubber plate.

[0018] There is a tripod support 1 outside the large turntable 13, and the three horizontal beams of the support 1 are located above the large turntable 13 and intersect at the center of the large turntable.

[0019] Each horizontal beam is respectively provided with a radial disk shifting mechanism: the mechanism consists of a radial screw 4, a radial guide rail 5 and a radial seat frame 6 driven by the radial screw 4 and can move radially. And the stepper motor 2 that drives the radial screw 4.

[0020] All be provided with vertical lifting mechanism on each radial seat frame 6: this mechanism is by a vertical screw rod 8, vertical guide rail 9 and a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com