Method of repair of electronic device and repair system

A technology for electronic devices and repair methods, applied in electrical components, printed circuit parts, printed circuit maintenance/correction and other directions, can solve problems such as circuit board distortion, high temperature heating deterioration, and reduce the reliability of solder joints, to suppress distortion, The effect of gentle temperature changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

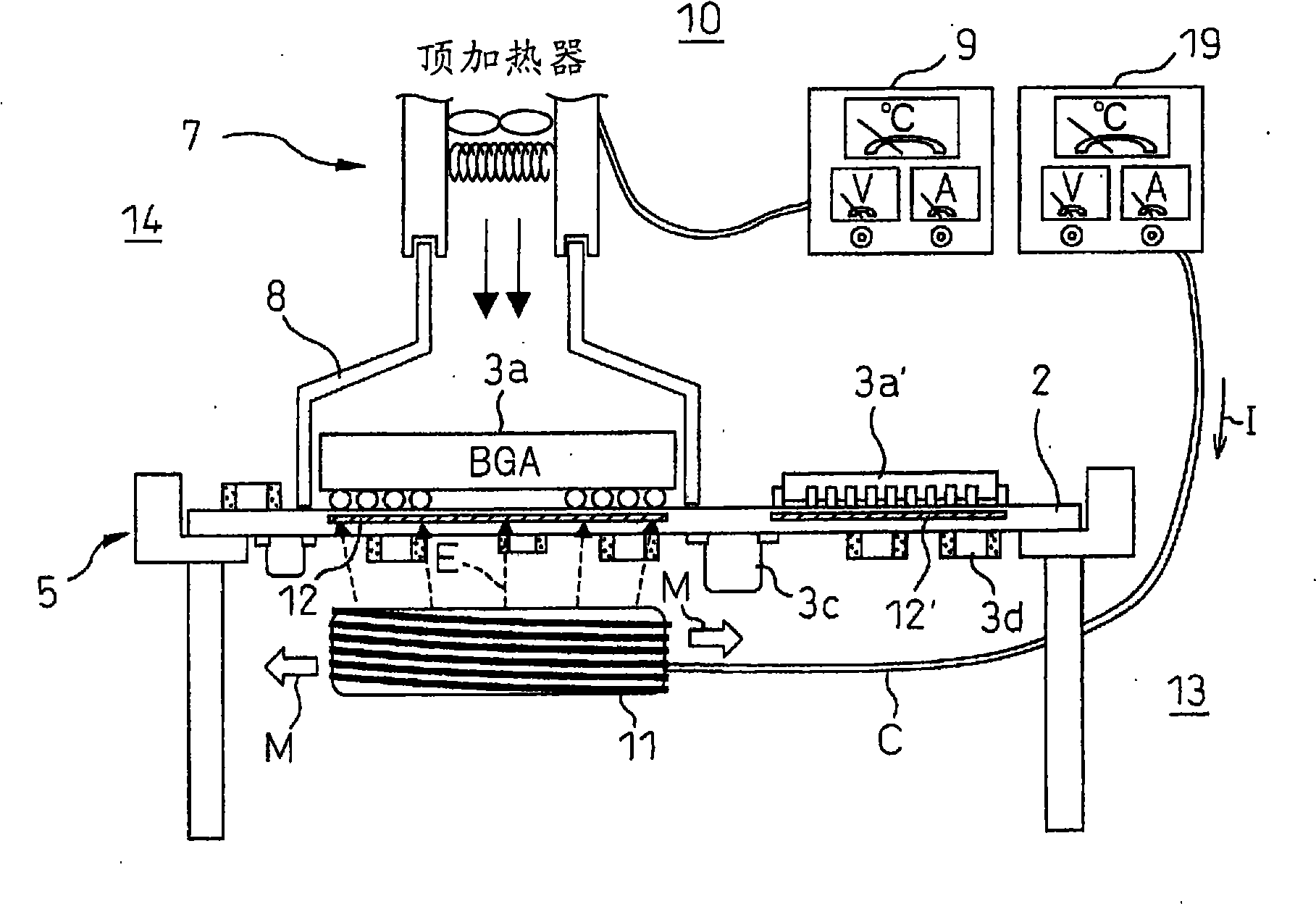

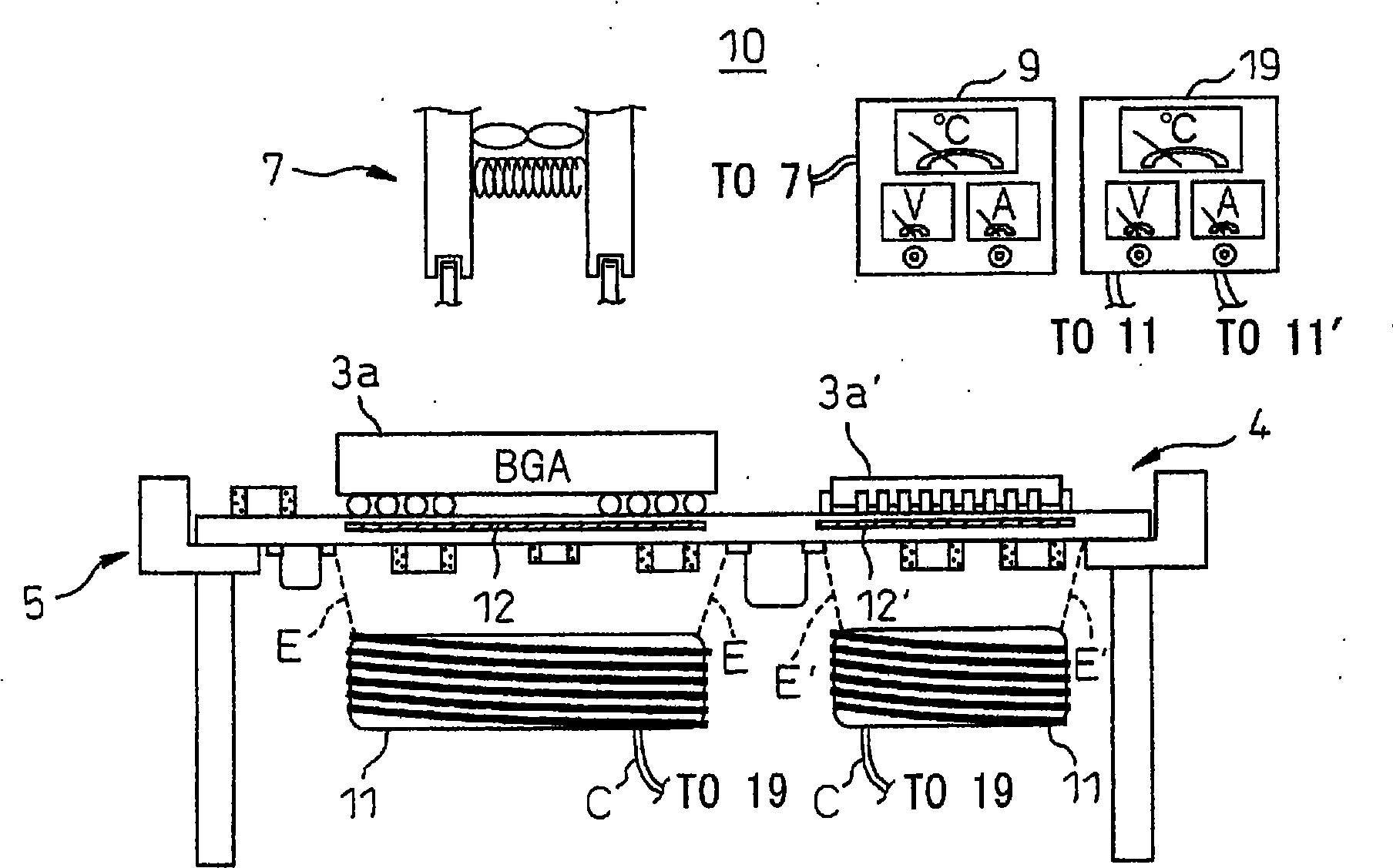

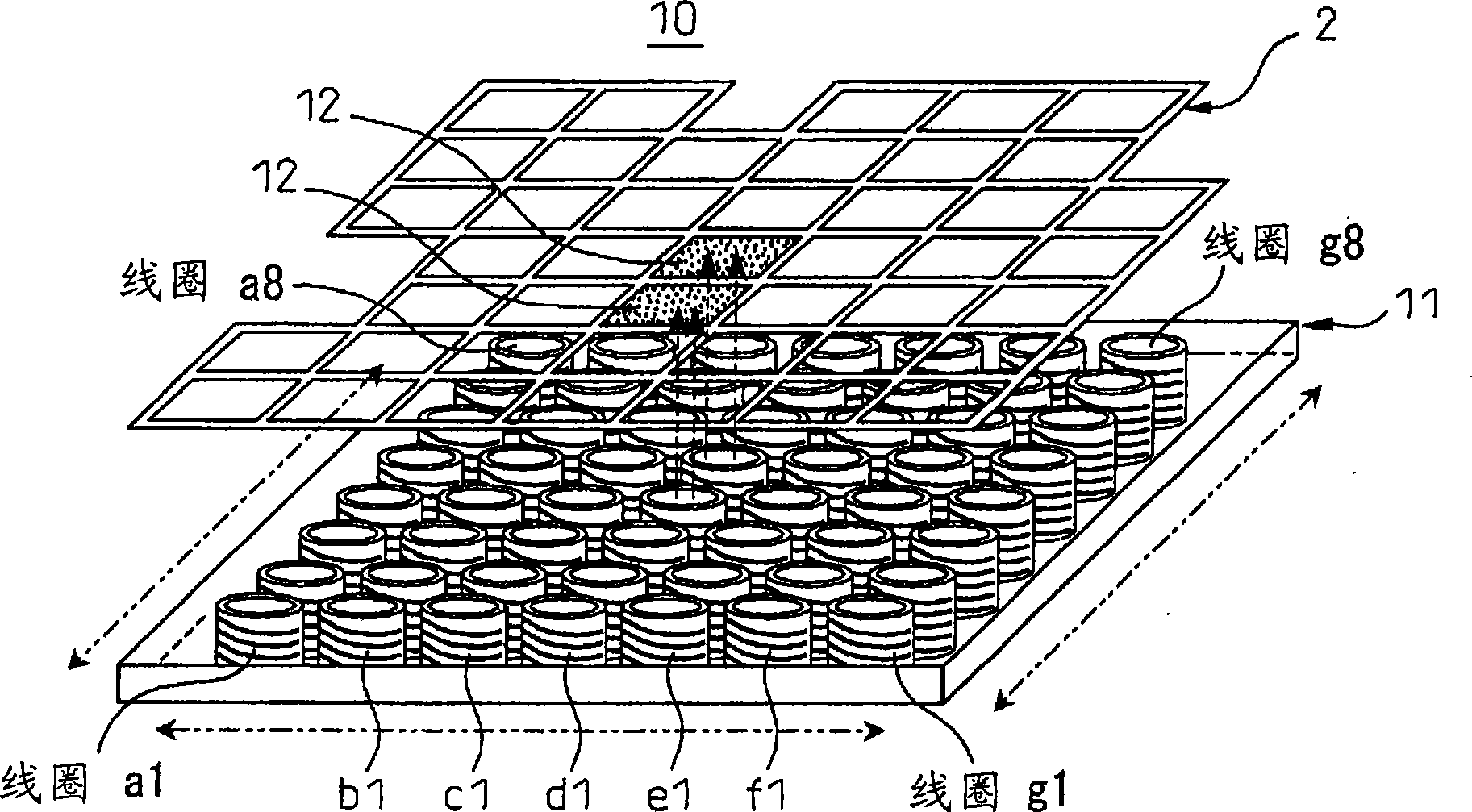

[0037] Before describing the embodiments, the prior art and its disadvantages are described with reference to the related drawings. In order to clarify the effect of the restoration system disclosed here, the conventional restoration system will be described first.

[0038] Figure 15 is a diagram showing a conventional restoration system 1 . In this figure, a plurality of electronic components 3a, 3b are mounted on the first surface (front side) of the circuit board 2 (for simplicity, only three are shown). Among these electronic devices, 3a denotes the above-mentioned BGA as an example of a large-sized device to be repaired (repaired device). 3b, on the other hand, represents an electronic device (IC) that generally does not need to be repaired.

[0039] On the second surface (back) of the circuit board 2 are mounted a plurality of electronic components 3c, 3d (seven are shown for simplicity). Among these electronic devices, 3c denotes an electrolytic capacitor as an exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com